Continuous overflowing type membrane filtering device and method

A membrane filtration and over-flow technology, applied in the field of liquid solute concentration or filtration devices, continuous over-flow membrane filtration devices, can solve the problems of low membrane flux, intensive pressure pump, membrane element pollution, etc. Membrane filtration benefits, high safety and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

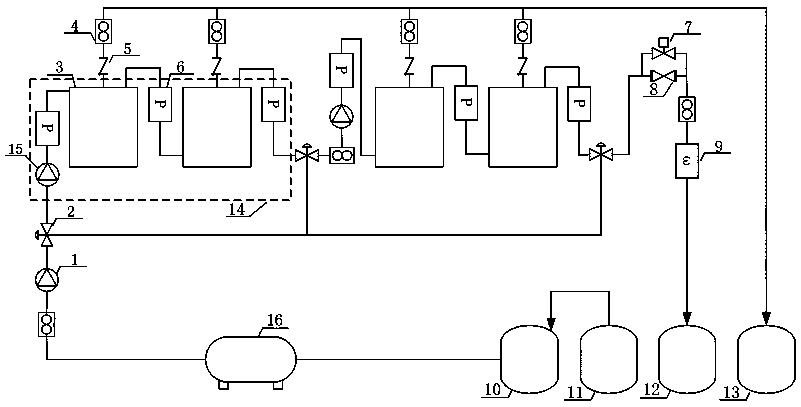

[0029] Such as figure 1 As shown, a continuous overflow membrane filtration device includes a feed pump 1, a stock solution buffer tank 10, a stock solution tank 11, a concentrated solution tank 12, and a dialysate tank 13, and is characterized in that it includes 2 filter modules connected in series 14. Each filter module 14 includes 2 sections of filter groups 3 connected in series in sequence, and the number of membrane shells in each filter group 3 decreases successively; the filter groups 3 are connected in series through a feeding pipe, and the input ends of each filter module 14 are provided with increasing Press the pump 15, the filtrate output end of each section of the filtration group 3 is connected to the dialysate tank 13 after converging, the thick liquid output end of the second filter module 14 is connected to the concentrated solution tank 12, and the output end of the stock solution tank 11 is connected to the The feed pump 1 is connected to the input end of ...

Embodiment 2

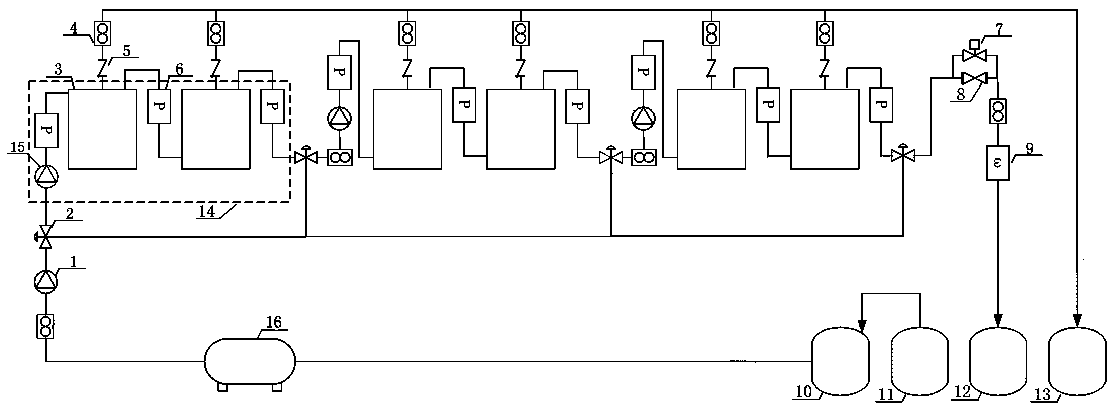

[0039] Such as figure 2 As shown, a continuous membrane concentration device includes a feed pump 1, a stock solution buffer tank 10, a stock solution tank 11, a concentrated solution tank and a dialysate tank 13, and is characterized in that: it includes 3 concentration modules connected in series in sequence, each concentration The module includes 2 sections of filter groups 3 connected in series in sequence, and the number of membrane shells in each filter group 3 decreases successively; the filter groups 3 are connected in series through feeding pipes, and the input ends of each concentration module are provided with a booster pump 15, and each The filtrate output ends of the section filtration group 3 are connected to the dialysate tank 13 after converging, the strong liquid output end of the third concentration module is connected to the concentrate tank, and the output end of the stock solution tank 11 is connected to the input end of the stock solution buffer tank 10, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com