Hand-held descaling device and descaling method for a voltage equalizing electrode based on ultrasonic waves

A pressure-equalizing electrode and ultrasonic technology, applied in the field of cooling system, can solve the problems of cumbersome removal of pressure-equalizing electrodes, blockage of cooling water pipes, loose sealing gaskets, etc., and achieve the effect of improving battery life, light weight and ensuring safe operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The technical solutions in the embodiments of the present invention will be described clearly and in detail below with reference to the accompanying drawings in the embodiments of the present invention. The described embodiments are only some of the embodiments of the invention.

[0038] The technical scheme that the present invention solves the above-mentioned technical problems is:

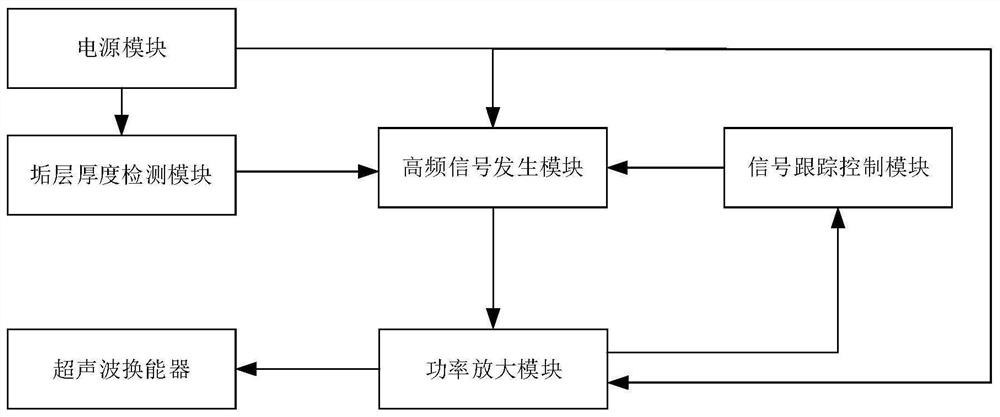

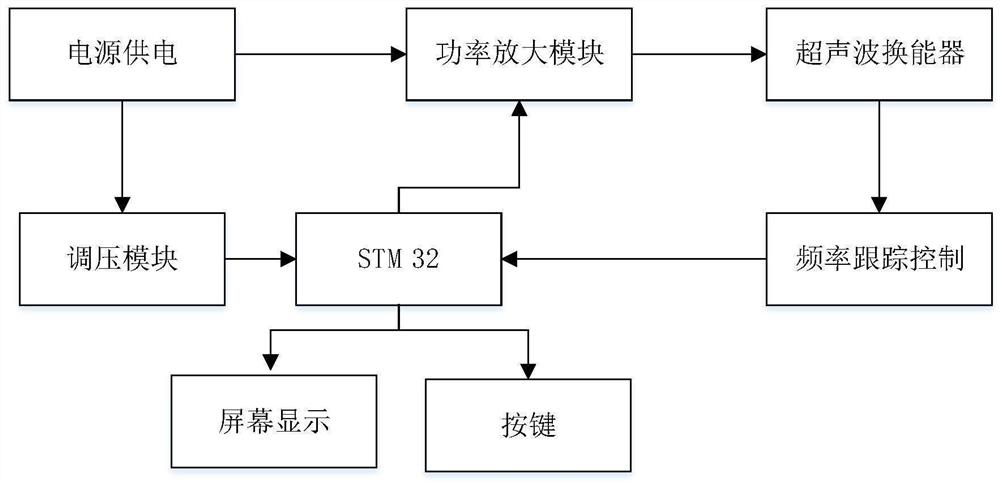

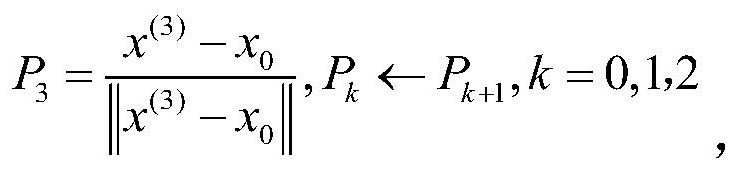

[0039] like figure 1 As shown in the figure, an ultrasonic-based pressure equalizing electrode handheld descaling device includes: a power module, a scale thickness detection module, a high-frequency signal generation module, a high-frequency signal detection module, a power amplification module, and a signal tracking control module. and an ultrasonic transducer, wherein the power supply module is respectively electrically connected with the scale layer thickness detection module, the high frequency signal generation module and the power amplification module, the scale layer thickness de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com