Production method of super-hydrophobic ice coating for ship deck deicing

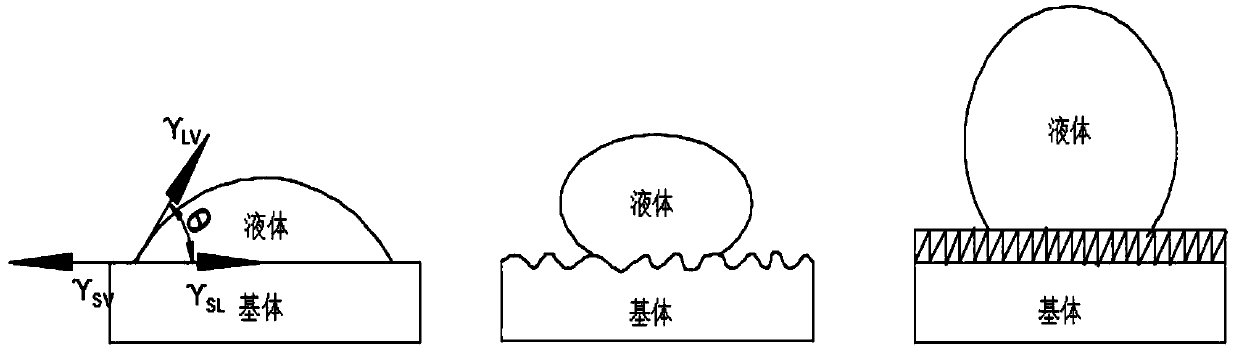

A ship deck and coating technology, applied to the hull deck, coating, hull, etc., can solve the problems of difficult operation of equipment, consume a lot of energy, consume less energy, etc., to reduce the chance of ice nucleation, small contact area, The effect of low adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Such as Figure 1-6 As shown, the present invention will be described in detail below in conjunction with specific embodiments. The described examples are helpful for the understanding and implementation of the present invention, and do not constitute limitations to the present invention; the scope of protection of the present invention is not limited to specific embodiments. Rather, it is defined by the claims;

[0037] 1. Dissolve 30mL TEOS in a certain amount of absolute ethanol to form a 350mL mixture and put it in a 500mL three-necked flask;

[0038] 2. Configure distilled water solution: the volume ratio of distilled water and ammonia water is 2:7;

[0039] 3. Turn on the electric stirrer, and evenly drop the distilled aqueous solution into the three-necked flask at a speed of 15mL / min, and continue to stir for 1 hour to obtain nano-SiO 2 solution;

[0040] 4. Incorporate nano-SiO 2 The solution was dried in a drying oven at 120°C for 24 hours to obtain nano-S...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com