Method for removing zinc, calcium and magnesium ions in manganese sulfate solution by synergistic extraction method

A manganese sulfate solution and extraction technology, which is applied in the field of hydrometallurgy, can solve the problems such as the inability of the extractant to be recycled for a long time, the high water solubility of the extractant, the residual fluoride ion, etc., so as to save energy and auxiliary materials, and reduce the water solubility. , the effect of less consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

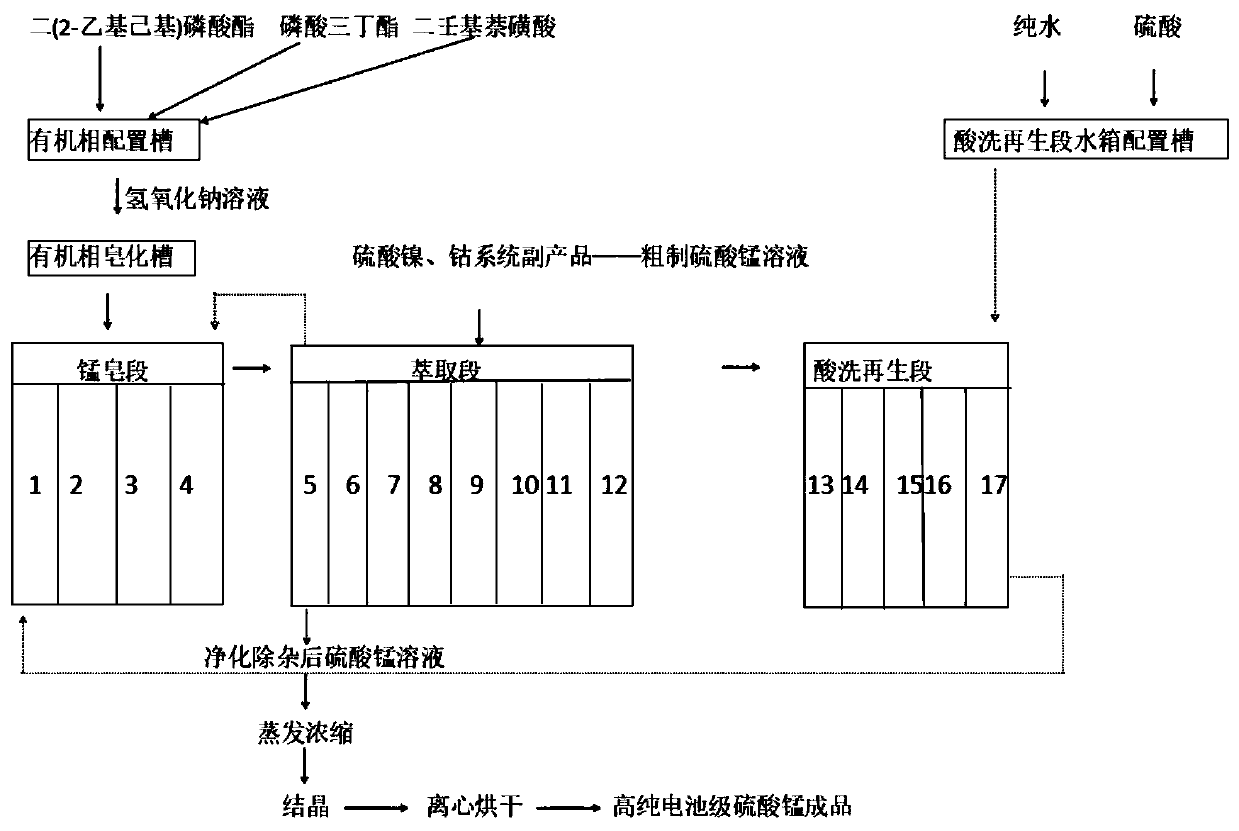

[0023] The method for removing zinc, calcium and magnesium ions in manganese sulfate solution by cooperative extraction is characterized in that, comprising the following steps:

[0024] Step 1. According to the weight ratio of di(2-ethylhexyl) phosphate, tributyl phosphate and dinonyl naphthalene sulfonic acid, the extractant is configured in a ratio of 5:2:3, and the volume ratio of extractant to sulfonated kerosene is Adding sulfonated kerosene to the extractant at a ratio of 3:7 is configured as an organic phase with an extractant concentration of 30%; the crude manganese sulfate solution is the water phase; the pH of the crude manganese sulfate solution is 2.0, and the crude The content of each element in the manganese sulfate solution is manganese 115g / L, iron 0.0008g / L, zinc 8.55g / L, calcium 0.3g / L, magnesium 0.005g / L, nickel 0.003g / L, sodium 0.005g / L;

[0025] Step 2, adding the organic phase configured in step 1 into a sodium hydroxide solution with a concentration of...

Embodiment 2

[0032] The method for removing zinc, calcium and magnesium ions in manganese sulfate solution by cooperative extraction is characterized in that, comprising the following steps:

[0033] Step 1. According to the weight ratio of di(2-ethylhexyl) phosphate, tributyl phosphate and dinonyl naphthalene sulfonic acid, the extractant is configured in a ratio of 5:1.5:3.5, and the volume ratio of extractant to sulfonated kerosene is Adding sulfonated kerosene into the extractant at a ratio of 3:7 is configured as an organic phase with an extractant concentration of 30%; the crude manganese sulfate solution is the water phase; the pH of the crude manganese sulfate solution is 1.7, and the crude The content of each element in the manganese sulfate solution is manganese 122g / L, iron 0.0009g / L, zinc 8.13g / L, calcium 0.26g / L, magnesium 0.003g / L, nickel 0.004g / L, sodium 0.001g / L;

[0034] Step 2, adding the organic phase configured in step 1 into a sodium hydroxide solution with a concentra...

Embodiment 3

[0041] The method for removing zinc, calcium and magnesium ions in manganese sulfate solution by cooperative extraction is characterized in that, comprising the following steps:

[0042] Step 1. According to the weight ratio of di(2-ethylhexyl) phosphate, tributyl phosphate and dinonyl naphthalene sulfonic acid, the extractant is configured in a ratio of 5:1.5:3.5, and the volume ratio of extractant to sulfonated kerosene is Adding sulfonated kerosene into the extractant at a ratio of 2:8 is configured as an organic phase with an extractant concentration of 20%; the crude manganese sulfate solution is the water phase; the pH of the crude manganese sulfate solution is 2.5, and the crude The content of each element in the manganese sulfate solution is manganese 95g / L, iron 0.0003g / L, zinc 9.71g / L, calcium 0.20g / L, magnesium 0.005g / L, nickel 0.002g / L, sodium 0.001g / L;

[0043] Step 2, adding the organic phase configured in step 1 to a sodium hydroxide solution with a concentratio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Acidity | aaaaa | aaaaa |

| Acidity | aaaaa | aaaaa |

| Acidity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com