Environment-friendly composition for thermoplastic polyurethane foam and application thereof

A thermoplastic polyurethane and composition technology, which is applied in the field of thermoplastic polyurethane foam and composition for environment-friendly thermoplastic polyurethane foam, can solve problems such as easy occurrence of delamination, and achieve the effects of good sound absorption performance and good thermal insulation performance.

Inactive Publication Date: 2020-08-14

上海玓墨化工科技有限公司

View PDF3 Cites 1 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Most of the compositions currently on the market add a cell opener, such as Evonik Specialty Chemicals O-501. After adding a cell opener, the composition is prone to delamination during placement, and it needs to be mixed again before use; at the same time, the composition Physical blowing agents are also added, such as fluorodichloroethane (HCFC-141b), dichloromethane, pentafluoropropane (HFC-245fa), 1,1,1,3,3-pentafluorobutane (HFC -365mfc) and other low-boiling blowing agents to assist foaming and cell opening, these blowing agents have problems with ozone depletion potential (ODP) and / or high greenhouse gas effect (GWP)

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

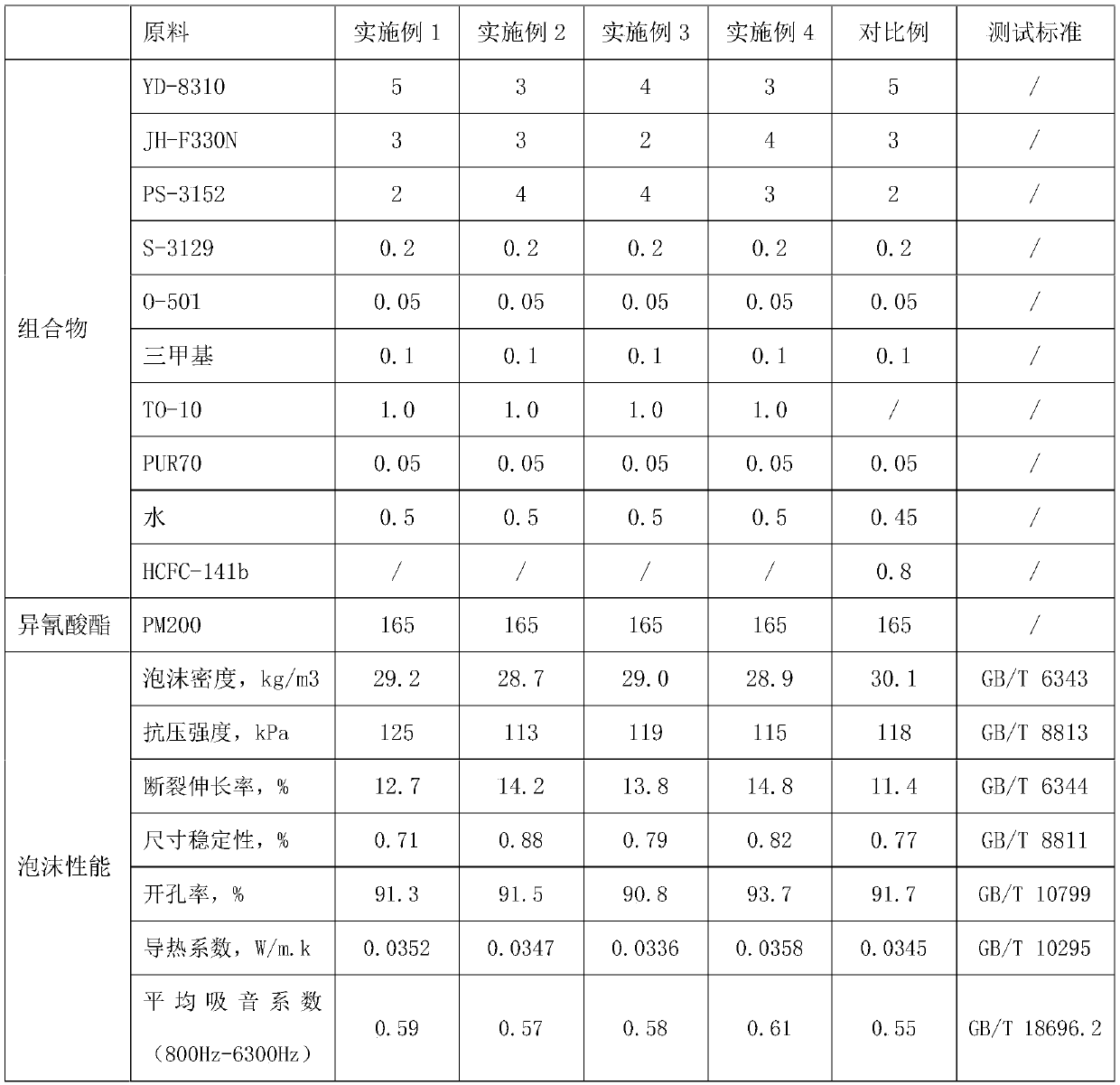

[0042] Embodiment: preparation environment-friendly thermoplastic polyurethane foam composition and thermoplastic polyurethane foam

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention discloses an environment-friendly composition for thermoplastic polyurethane foam and application thereof. Polyether polyol A, polyether polyol B and polyester polyol C are used as mainraw materials, an organosilicon surfactant, a pore opening agent, a catalyst, water and an emulsifier are used as assistants, no chlorofluorocarbon physical foaming agent is added, and the compositionhas a good environmental effect; the emulsifier is an environment-friendly product, and the composition does not contain a nonylphenol emulsifier, and is non-toxic and harmless to a human body; meanwhile, a reactive catalyst is adopted, so that organic volatile matters in the foam product are reduced. The thermoplastic polyurethane foam obtained through foaming is of an open-cell structure, the foam density is 30 kg / m<3>, the compressive strength is larger than or equal to 100 kPa, the aperture ratio is larger than or equal to 90%, the elongation at break is larger than or equal to 10%, and good sound absorption performance and good heat preservation performance are achieved.

Description

technical field [0001] The invention relates to an environment-friendly thermoplastic polyurethane foam composition and the thermoplastic polyurethane foam prepared by foaming the composition, belonging to the technical field of chemical synthesis. Background technique [0002] Sound absorption and sound insulation are important measures for noise reduction in automobiles. The materials used must be environmentally friendly, light in weight, good in strength, corrosion-resistant, and insect-proof. Thermoplastic polyurethane foam is a porous material and the pores are interconnected to form continuous voids, which have the functions of sound absorption and noise reduction; at the same time, thermoplastic polyurethane foam has the advantages of strong foam density, excellent mechanical properties, and mildew resistance; therefore, 80% of high-end cars currently use thermoplastic Polyurethane foam is used as a sound insulation material, and thermoplastic polyurethane foam also ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C08G18/40C08G18/42C08G18/48C08J9/08C08G101/00

CPCC08G18/4018C08G18/4211C08G18/4816C08G2110/0083

Inventor 信延垒任丽任洁洁

Owner 上海玓墨化工科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com