Treatment method for full-amount resource utilization of municipal wet garbage

A treatment method and resource recovery technology, applied in the field of organic solid waste environmental protection, can solve the problems of reducing the possibility of resource utilization of nutrients, high risk of breeding, and insufficient land, so as to improve the benefits of carbon sequestration and emission reduction, and increase biogas production efficiency, and the effect of avoiding carbon emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

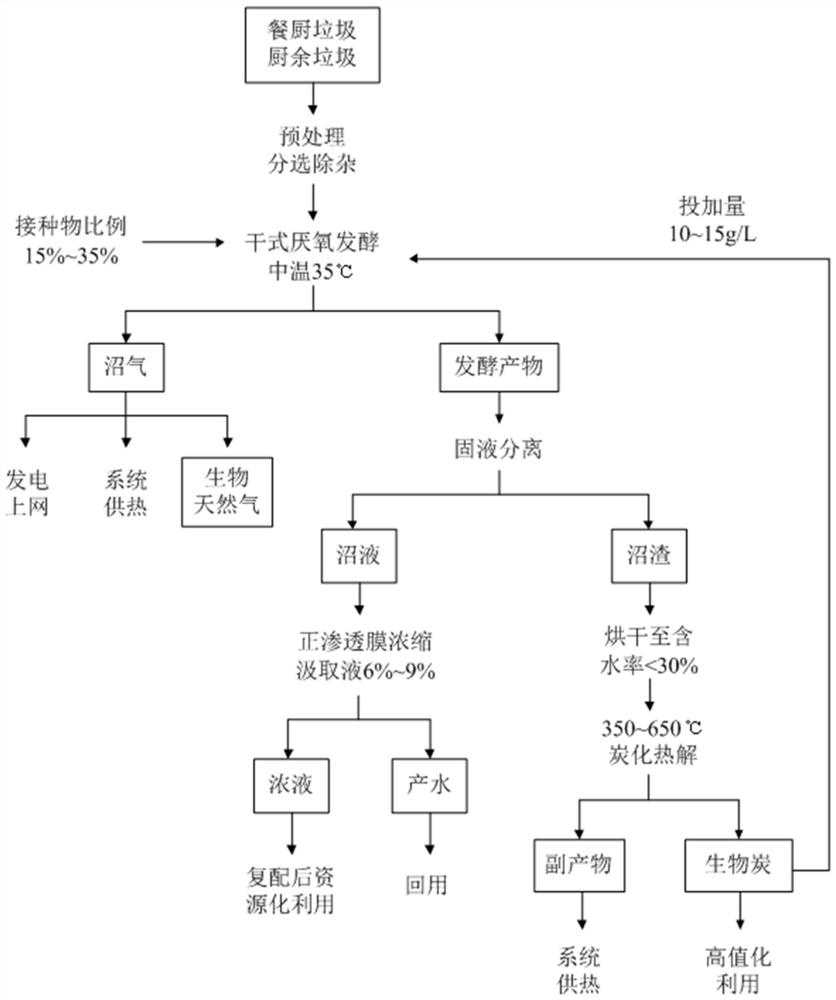

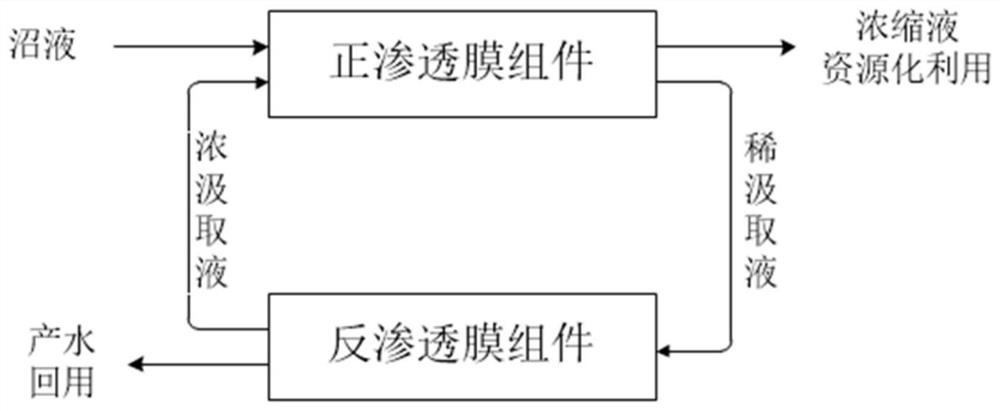

[0048] In this embodiment, municipal wet garbage is used as raw material, and all products after anaerobic fermentation are fully utilized as resources. The system includes the following steps:

[0049] Anaerobic fermentation of kitchen waste: Kitchen waste is first pretreated to complete sorting, impurity removal, and pulping, then put inoculation sludge at 25%, add biochar at 15g / L, and biogas slurry backflow to adjust the moisture content of the material to 80 %, medium-temperature dry anaerobic fermentation is adopted, the fermentation temperature is 35°C, and the fermentation time is 25 days. Biogas and fermentation mixture are produced after anaerobic fermentation. Part of the biogas provides heat for the entire system through heating equipment, and the rest is powered to the grid through the power generation system;

[0050] Preparation of biochar from biogas residue: the solid phase after dehydration of the fermentation mixture is biogas residue, the drying temperature is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com