Concrete admixture and preparation method thereof

A concrete admixture and monomer technology, which is applied in sustainable waste treatment, solid waste management, climate sustainability, etc., can solve the problems of high cost and mass use, unsatisfactory performance, and inability to meet the technical requirements of filling mining production. , to achieve the effect of low cost, short production cycle and good environmental effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

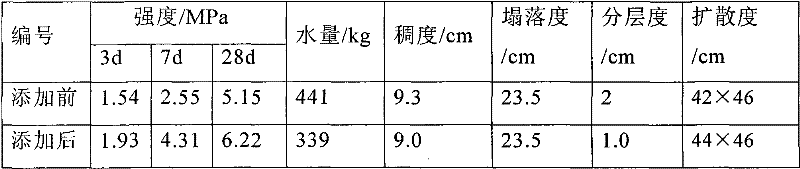

Embodiment 1

[0039] A preparation method of concrete admixture, the method comprises the following steps:

[0040] (1) Prepare materials according to the following components and contents: methacrylic acid 3kg, polyethylene glycol monoether acrylate monomer 25kg, allyl sodium sulfonate 1kg, polyether acrylate monomer 0.5kg, ferrous sulfate 5kg , industrial salt 4kg, fly ash 5kg, 325 mesh calcium carbonate powder 8kg;

[0041] (2) Place methacrylic acid, polyethylene glycol monoether acrylate monomer, sodium allyl sulfonate and polyether acrylate monomer in a reactor for copolymerization reaction, control the reaction temperature to 55°C, and react The time is 3h, obtain copolymer, store separately;

[0042] (3) Control the reaction temperature to 30°C, mix and stir ferrous sulfate and industrial salt for 1 min, then add fly ash and calcium carbonate powder therein, continue stirring for 5 min to obtain the mixture, and store it separately;

[0043] (4) Mix the copolymer and the mixture a...

Embodiment 2

[0053] A preparation method of concrete admixture, the method comprises the following steps:

[0054] (1) Prepare materials according to the following components and contents: methacrylic acid 6kg, polyethylene glycol monoether acrylate monomer 12kg, allyl sodium sulfonate 2kg, polyether acrylate monomer 1kg, ferrous sulfate 25kg, Industrial salt 20kg, fly ash 1kg, 425 mesh calcium carbonate powder 15kg;

[0055] (2) Place methacrylic acid, polyethylene glycol monoether acrylate monomer, sodium allyl sulfonate and polyether acrylate monomer in a reactor for copolymerization reaction, control the reaction temperature to 90°C, and react The time is 0.5h to obtain the copolymer, which is stored separately;

[0056] (3) Control the reaction temperature to 15°C, mix and stir ferrous sulfate and industrial salt for 2 minutes, then add fly ash and calcium carbonate powder therein, continue stirring for 8 minutes to obtain the mixture, and store it separately;

[0057](4) Mix the co...

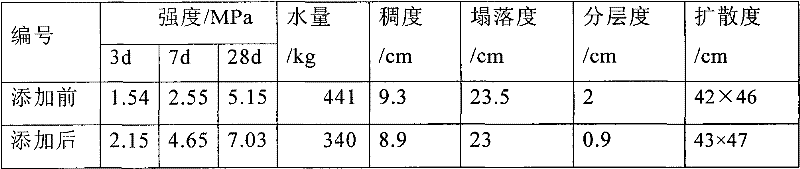

Embodiment 3

[0067] A preparation method of concrete admixture, the method comprises the following steps:

[0068] (1) Prepare materials according to the following components and contents: methacrylic acid 5kg, polyethylene glycol monoether acrylate monomer 20kg, allyl sodium sulfonate 2kg, polyether acrylate monomer 1kg, ferrous sulfate 20kg, Industrial salt 10kg, fly ash 3kg, 400 mesh calcium carbonate powder 10kg;

[0069] (2) Place methacrylic acid, polyethylene glycol monoether acrylate monomer, sodium allyl sulfonate and polyether acrylate monomer in a reactor for copolymerization reaction, control the reaction temperature to 80°C, and react Time is 2h, obtains copolymer;

[0070] (3) Control the reaction temperature to be 20° C., mix and stir ferrous sulfate and industrial salt for 2 minutes, then add fly ash and calcium carbonate powder therein, and continue stirring for 6 minutes to obtain a mixture;

[0071] (4) Mix the copolymer and the mixture at room temperature for 6 minute...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| slump | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com