Two-component polyurethane binding agent and grinding wheel applying same

A polyurethane binder and two-component technology, used in the field of polyurethane, can solve the problems of high brittleness and easy cracking of grinding wheels, and achieve the effects of strong activity, good product stability and improved toughness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

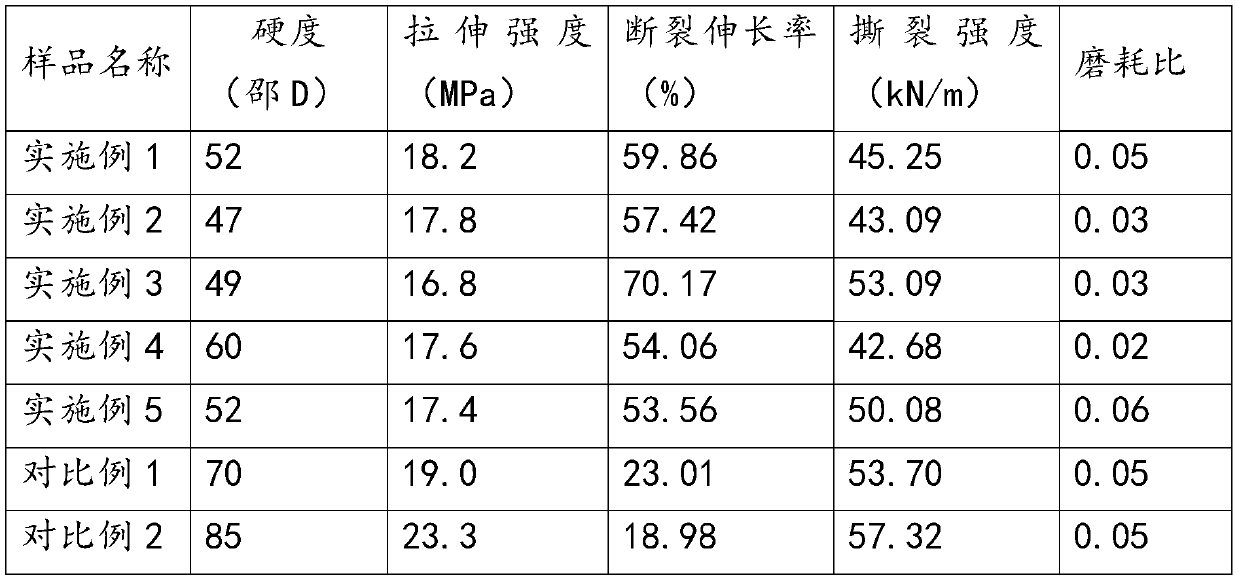

Examples

Embodiment 1

[0047] This embodiment relates to a two-component polyurethane binder, which forms the matrix of the grinding wheel after curing in the abrasive tool, wherein the two-component polyurethane binder specifically includes the following raw materials:

[0048] Combination material: 50 kg of polypropylene oxide polyether polyol with a functionality of 2 and a number average molecular weight of 200, 25 kg of a trimethylolpropane polyether polyol with a functionality of 3 and a number average molecular weight of 800, and a functionality of 3 , 25kg of polypropylene oxide polyether polyol with a number average molecular weight of 4800, 3kg of silane coupling agent KH550, 0.03kg of dibutyltin dilaurate, 1kg of 4A molecular sieve;

[0049] Isocyanate: PM200 75kg and liquefied MDI 25kg.

[0050] Two-component polyurethane binders are cured as follows:

[0051] After mixing the combination material and isocyanate in proportion, take 100kg combination material and 50kg isocyanate, mix and...

Embodiment 2

[0053] This embodiment relates to a two-component polyurethane binder, which forms the matrix of the grinding wheel after curing in the abrasive tool, wherein the two-component polyurethane binder specifically includes the following raw materials:

[0054] Combination material: 40kg of polypropylene oxide polyether polyol with a functionality of 2 and a number average molecular weight of 300, 35kg of trimethylolpropane polyether polyol with a functionality of 3 and a number average molecular weight of 800, and a functionality of 3, 25kg of polypropylene oxide polyether polyol with a number average molecular weight of 3000, 3kg of silane coupling agent KH550, 0.03kg of stannous octoate, 1kg of 4A molecular sieve;

[0055] Isocyanate: PM200 75kg and liquefied MDI 25kg.

[0056] Two-component polyurethane binders are cured as follows:

[0057] After mixing the combination material and isocyanate in proportion, take 100kg combination material and 50kg isocyanate, mix and stir eve...

Embodiment 3

[0059] This embodiment relates to a two-component polyurethane binder, which forms the matrix of the grinding wheel after curing in the abrasive tool, wherein the two-component polyurethane binder specifically includes the following raw materials:

[0060] Combination material: 50 kg of polypropylene oxide polyether polyol with a functionality of 2 and a number average molecular weight of 200, 25 kg of a trimethylolpropane polyether polyol with a functionality of 3 and a number average molecular weight of 500, and a functionality of 3, 25kg of polypropylene oxide polyether polyol with a number average molecular weight of 4800, 3kg of silane coupling agent KH550, 0.03kg of bismuth laurate, 1kg of 4A molecular sieve;

[0061] Isocyanate: PM200 100kg.

[0062] Two-component polyurethane binders are cured as follows:

[0063] After mixing the combination material and isocyanate in proportion, take 100kg combination material and 50kg isocyanate, mix and stir evenly, pour it into t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com