High-grade woodware artware coating and preparation method thereof

A technology for handicrafts and woodware, applied in the field of high-grade wood handicraft coatings and its preparation, can solve the problems affecting the protective performance of wooden handicrafts, lack of corrosion resistance, etc., achieve excellent anti-corrosion and protection, not easy to foam, mild reaction Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

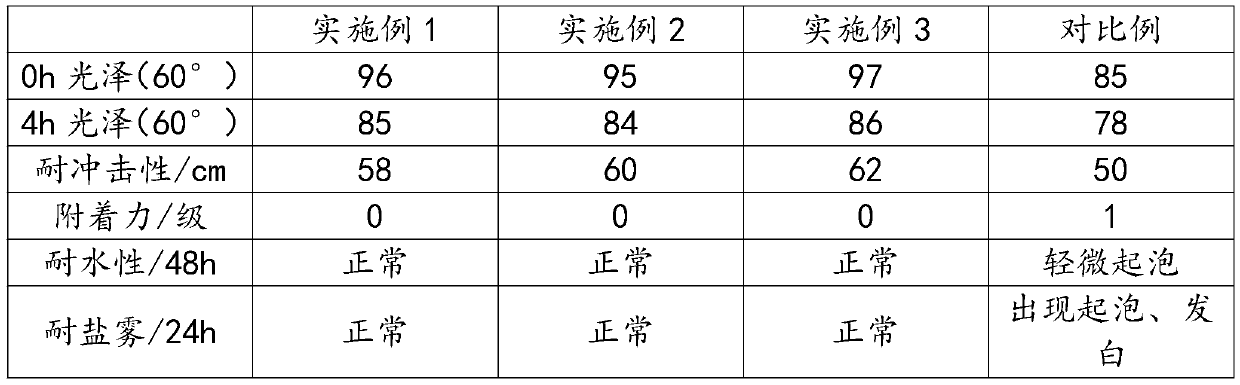

Examples

preparation example Construction

[0033] The preparation method of this coating is as follows:

[0034] The first step, after mixing water and modified epoxy resin, add graphene oxide, coupling agent, defoamer, substrate wetting agent, leveling agent and dipropylene glycol butyl ether while stirring, and then continue stirring for 25-30min , and then add the thickener, after adding, continue to stir for 10-20min, filter to obtain the primer;

[0035] The second step is to mix the primer and the curing agent evenly to prepare the coating.

Embodiment 1

[0037] A high-grade wood handicraft coating, including a primer and a curing agent, the primer includes the following raw materials in parts by weight: 60-70 parts by weight of modified epoxy resin, 2-3 parts of graphene oxide, 0.8-1 parts of coupling agent, and defoaming agent 0.2-0.3, 0.4-0.5 parts of thickener, 0.7-0.9 parts of substrate wetting agent, 0.1-0.2 parts of leveling agent, 4-5 parts of dipropylene glycol butyl ether, 12-15 parts of water;

[0038] The curing agent is polyisocyanate curing agent WT101, wherein the ratio of the amount of hydroxyl groups to isocyanate groups in the modified epoxy resin is controlled to be 1:1.3-1.4.

Embodiment 2

[0040] A high-grade wood handicraft coating, including a primer and a curing agent, the primer includes the following raw materials in parts by weight: 60-70 parts by weight of modified epoxy resin, 2-3 parts of graphene oxide, 0.8-1 parts of coupling agent, and defoaming agent 0.2-0.3, 0.4-0.5 parts of thickener, 0.7-0.9 parts of substrate wetting agent, 0.1-0.2 parts of leveling agent, 4-5 parts of dipropylene glycol butyl ether, 12-15 parts of water;

[0041] The curing agent is polyisocyanate curing agent WT101, wherein the ratio of the amount of hydroxyl groups to isocyanate groups in the modified epoxy resin is controlled to be 1:1.3-1.4.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com