Preparation process of high hydrophobic antibacterial polyurethane film

A technology of polyurethane film and preparation process, which is applied in rayon manufacturing, single-component synthetic polymer rayon, fiber chemical characteristics, etc., can solve the problems of shortened service life, weak antibacterial performance, poor hydrophobicity, etc., and achieve surface roughness The effect of increasing, excellent adsorption performance, and ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

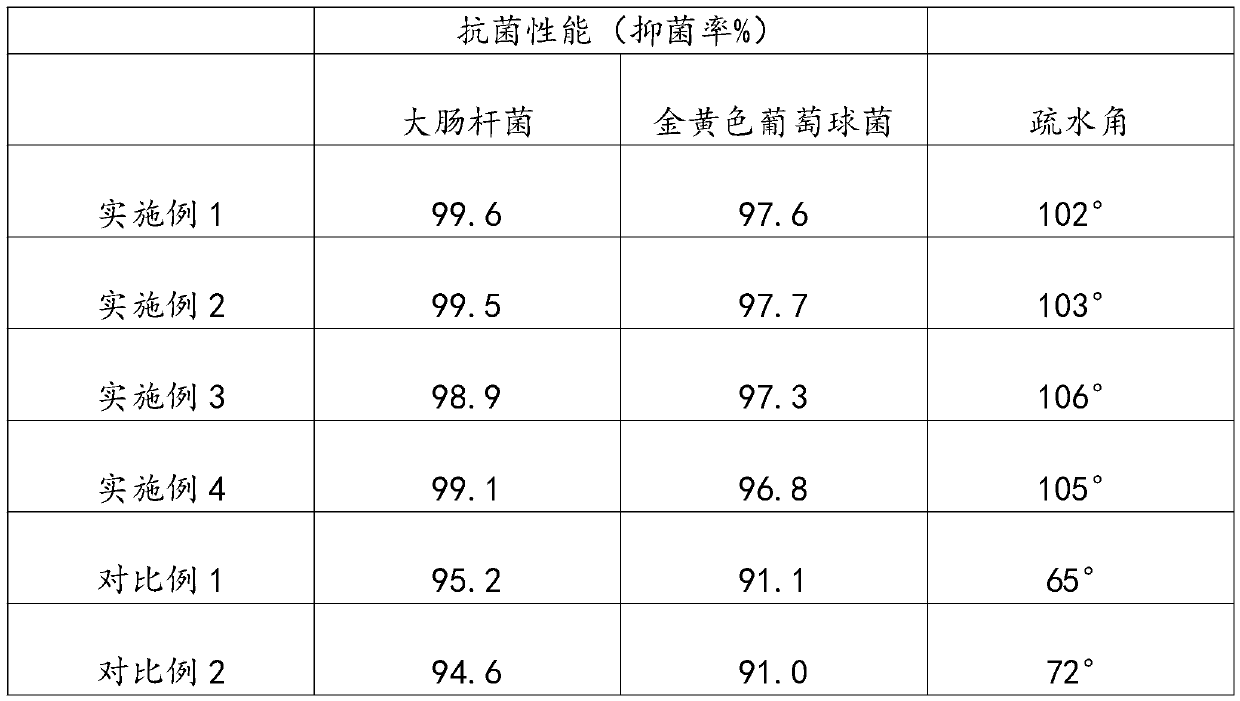

Examples

Embodiment 1

[0025] A preparation process for a highly hydrophobic antibacterial polyurethane film, comprising the steps of:

[0026] The first step, weighing the following raw materials by weight: 100 parts of acetone, 30 parts of fluorine-containing alkyl polyether glycol, 1 part of monobutyltin oxide, 20 parts of diisocyanate, 0.5 part of 1,4-butanediol, 5 parts of KH550, 20 parts of dimethylformamide, 3 parts of antibacterial agent;

[0027] The second step is to mix acetone and fluorine-containing alkyl polyether diol evenly, then add the mixed catalyst, stir magnetically for 30 minutes, then heat in a water bath at 40°C, and add diisocyanate dropwise, and control the dropping time for 3 minutes. React for 2 hours, then add 1,4-butanediol, stir at a constant speed and react for 5 hours, then add KH550, raise the temperature to 60°C, and react for 4 hours to obtain fluorine-containing polyurethane;

[0028] Step 3: Add fluorine-containing polyurethane to dimethylformamide, heat in a w...

Embodiment 2

[0033] A preparation process for a highly hydrophobic antibacterial polyurethane film, comprising the steps of:

[0034] The first step, weighing the following raw materials in parts by weight: 105 parts of acetone, 34 parts of fluorine-containing alkyl polyether glycol, 1 part of monobutyltin oxide, 25 parts of diisocyanate, 1.0 part of 1,4-butanediol, 6 parts of KH550, 25 parts of dimethylformamide, 4 parts of antibacterial agent;

[0035] The second step is to mix acetone and fluorine-containing alkyl polyether diol evenly, then add the mixed catalyst, stir magnetically for 30 minutes, then heat in a water bath at 40°C, and add diisocyanate dropwise, and control the dropping time for 3 minutes. React for 2 hours, then add 1,4-butanediol, stir at a constant speed and react for 5 hours, then add KH550, raise the temperature to 60°C, and react for 4 hours to obtain fluorine-containing polyurethane;

[0036]Step 3: Add fluorine-containing polyurethane to dimethylformamide, hea...

Embodiment 3

[0039] A preparation process for a highly hydrophobic antibacterial polyurethane film, comprising the steps of:

[0040] The first step, weighing the following raw materials by weight: 110 parts of acetone, 38 parts of fluorine-containing alkyl polyether glycol, 2 parts of monobutyltin oxide, 35 parts of diisocyanate, 1.2 parts of 1,4-butanediol, 8 parts of KH550, 40 parts of dimethylformamide, 4 parts of antibacterial agent;

[0041] The second step is to mix acetone and fluorine-containing alkyl polyether diol evenly, then add the mixed catalyst, stir magnetically for 30 minutes, then heat in a water bath at 40°C, and add diisocyanate dropwise, and control the dropping time for 3 minutes. React for 2 hours, then add 1,4-butanediol, stir at a constant speed and react for 5 hours, then add KH550, raise the temperature to 60°C, and react for 4 hours to obtain fluorine-containing polyurethane;

[0042] Step 3: Add fluorine-containing polyurethane to dimethylformamide, heat in a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com