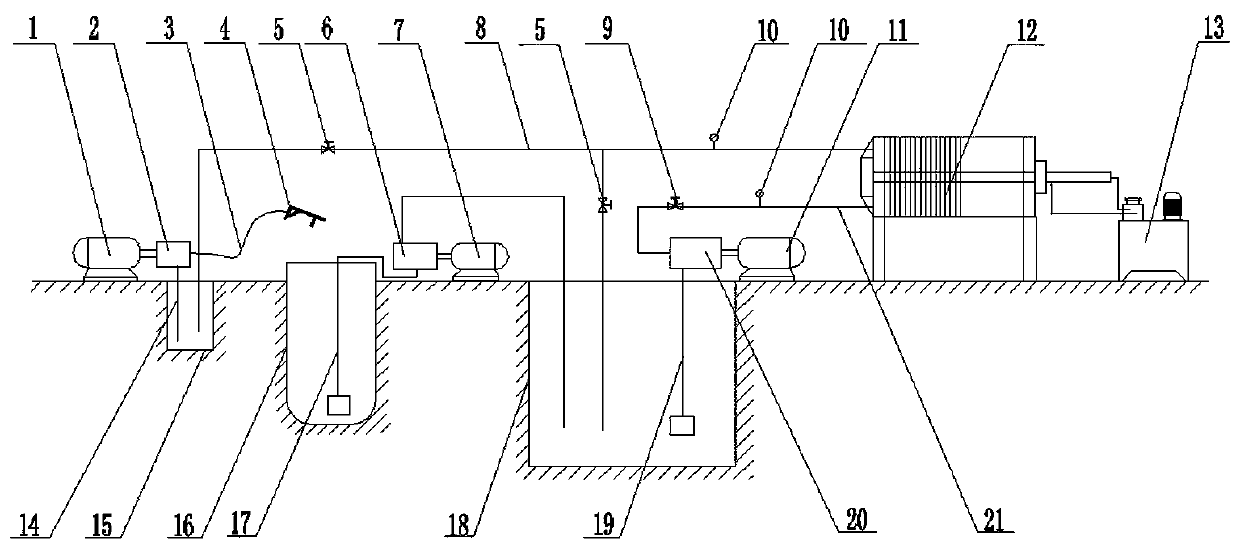

Rapid treatment device for internal attachments of magnesium alloy smelting crucible and treatment method thereof

A technology for smelting crucibles and processing devices, which is applied in the field of rapid processing devices for magnesium-containing metals and refining agent slurries, can solve the problems of ineffective reuse of water, low crucible utilization rate, and large manual workload, etc. Improve the effective utilization rate, reduce the labor intensity and save the soaking time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Take the cleaning of the inner wall of the crucible for the production of VW63 rare earth magnesium alloy products after the production of AZ31B magnesium alloy as an example.

[0046] AZ31B magnesium alloy products contain more aluminum elements, and VW63 magnesium alloy needs to strictly control the content of aluminum elements, so the requirements for the cleanliness of the inner wall of the crucible are extremely high. The specific cleaning process is as follows:

[0047] First, according to the normal AZ31B magnesium alloy smelting crucible treatment method, clean up the residual metal liquid in the crucible as much as possible, after the cleaning is completed, power off and cool down, after the temperature in the crucible drops to 400°C, water is injected into the crucible to produce circulating water, and the circulating water soaks the crucible 18h (After the production circulating water is injected, a large amount of water vapor overflows, which needs to be extr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com