Nickel-cobalt bimetallic oxide composite material, nickel-cobalt bimetallic sulfide composite material and supercapacitor

A double metal oxide and composite material technology, applied in the field of supercapacitor electrode materials, can solve the problems of low energy density and limited application of supercapacitors, and achieve the effects of excellent electrochemical performance, high power density and good conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] (1-1) Weigh 0.13g (0.003mol) NaOH, pour it into a 50mL beaker, add a mixed solution of 9mL absolute ethanol and 1mL deionized water, stir on a constant temperature magnetic stirrer until the solid is completely dissolved, then , add 0.4626g (0.003mol) thiosalicylic acid, at room temperature, stir for 30min, until the thiosalicylic acid is completely dissolved, to obtain solution A;

[0033] (1-2) Weigh 0.1785g (0.00075mol) CoCl 2 ·6H 2 O and 0.1782g (0.00075mol) NiCl 2 ·6H 2 O was added to a 25mL beaker and dissolved in 5mL of deionized water to obtain solution B;

[0034] (1-3) Add solution B dropwise to solution A, and continue to stir for 30 minutes;

[0035] (1-4) Pour the mixed solution into a 50mL reaction kettle, seal it, and react it in a 120°C electric blast drying oven for 96h. After washing for the first time, dry it in an electric blast drying oven at 80°C to obtain a black solid powder, that is, a nickel-cobalt double metal complex;

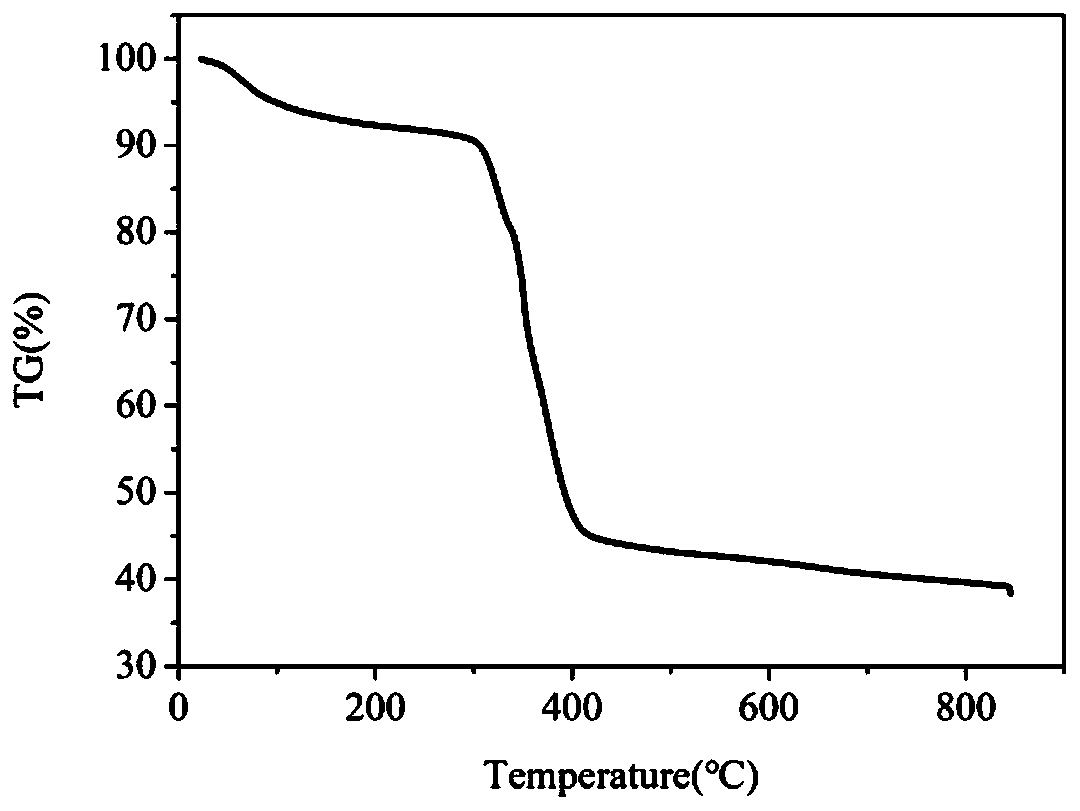

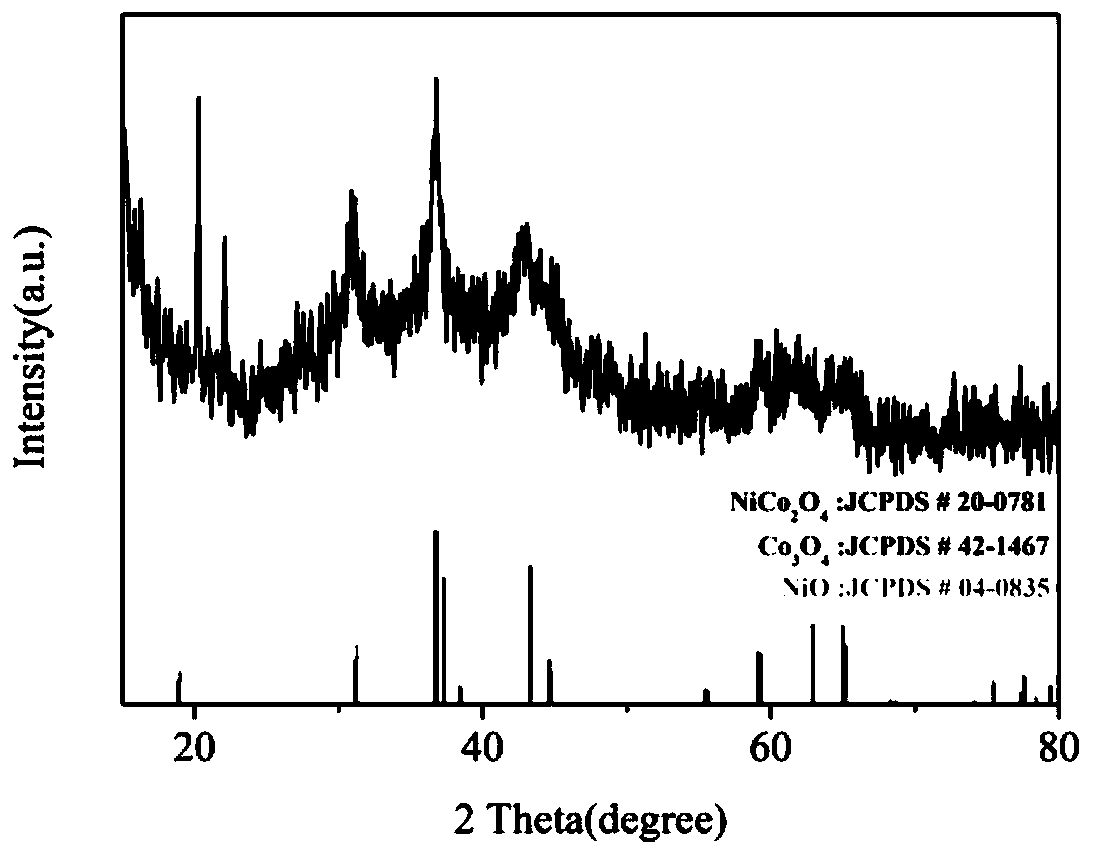

[0036] (1-5) Put...

Embodiment 2

[0040] (2-1) Weigh 0.15 g of the nickel-cobalt double metal oxide composite material prepared in Example 1 and 0.03 g of thioacetamide according to a mass ratio of 5:1, and add thioacetamide to a 25 mL beaker, Dissolve in 15mL of deionized water, stir on a constant temperature magnetic stirrer for 15min, after the dissolution is complete, add nickel-cobalt double metal oxide composite material, and continue stirring for 30min;

[0041] (2-2) Pour all the mixed solution into a 25mL reaction kettle, seal it, and react it in an electric blast drying oven at 160°C for 10h. After the reaction is completed, cool it to room temperature to obtain the product;

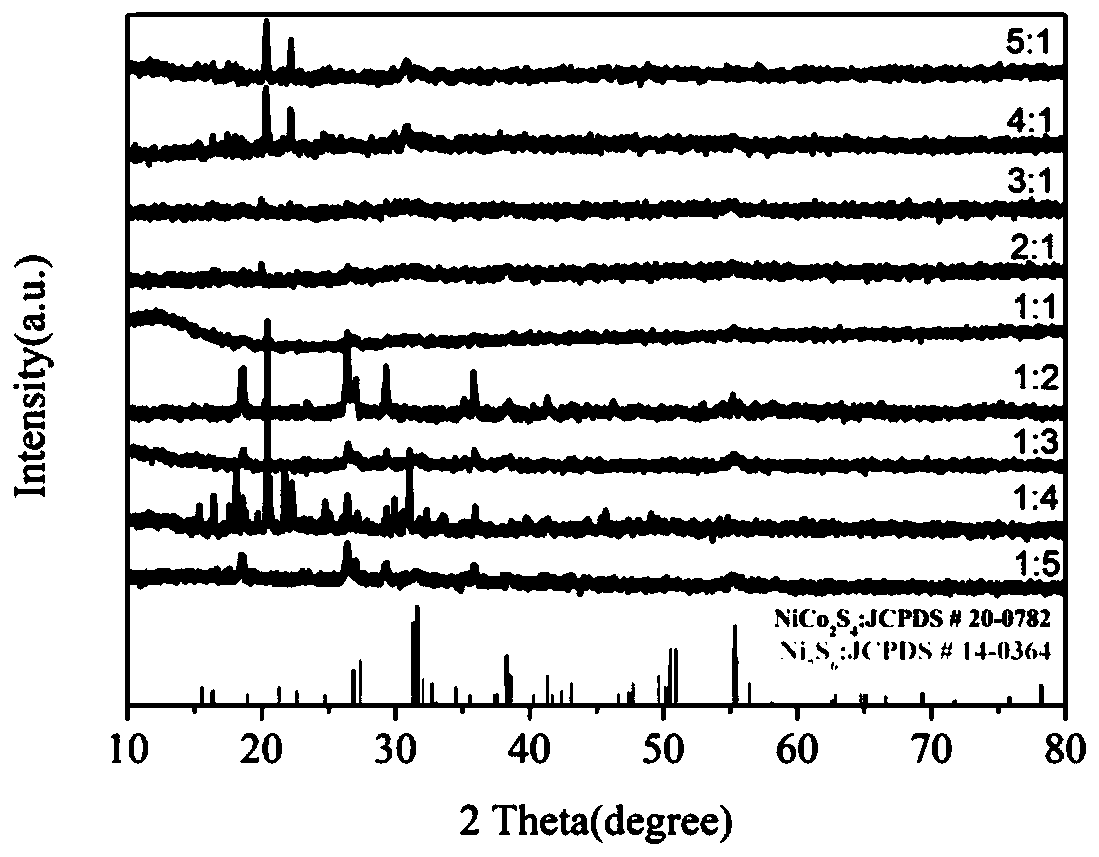

[0042] (2-3) The product is washed several times with deionized water, and dried in an electric blast drying oven at 60°C to obtain a nickel-cobalt bimetallic sulfide composite material, which is represented by 5:1 in the accompanying drawings. Using the same vulcanization method, according to the mass ratio of nickel-cobalt doub...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com