Preparation method of functionalized graphene roll hydrovoltaic PN junction

A technology of aminated graphene and carboxylated graphene, which is applied in the field of preparation of wet-gas power generation devices, can solve problems such as cost increase and ecological damage, and achieve the effects of increasing power generation, low equipment requirements, and easy availability of materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] (1) disperse 100mg graphene oxide in water, add 6g sodium hydroxide and 5g monochloroacetic acid, ultrasonic 3h, obtain carboxylated graphene; disperse 100mg graphene oxide in 100mLDMF, add 15g ethylenediamine and 5g Cyclohexylcarboimide was reacted at 120°C for 48h to obtain aminated graphene.

[0029] (2) Carboxylated graphene and aminated graphene were respectively dispersed in ethanol to obtain a slurry, and the concentration of carboxylated graphene and aminated graphene was 4 mg / mL.

[0030] (3) Heating the prepared carboxylated graphene and aminated graphene-graphene solution, and putting the graphene oxide solution into liquid nitrogen to cool after boiling until the solution is completely frozen, and then freezing it in situ Dry to obtain carboxylated graphene rolls and aminated graphene rolls.

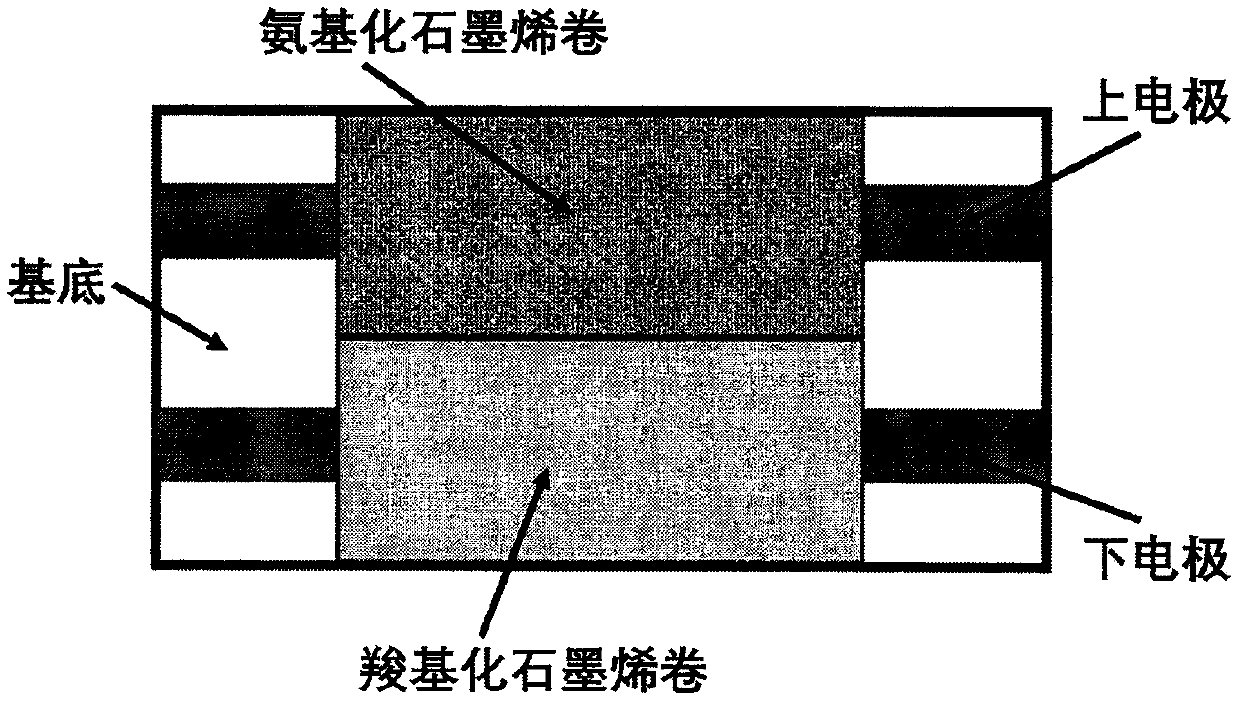

[0031] (4) Two graphene oxide layers are coated on the base polyester resin film, the electrode width is 1cm, the electrode length is 20cm, and the interval between t...

Embodiment 2

[0035] (1) Disperse 100mg of single-sided selective graphene oxide in water, add 6g of sodium hydroxide and 5g of monochloroacetic acid, and ultrasonicate for 3h to obtain carboxylated graphene; disperse 100mg of single-sided selective graphene oxide in 100mLDMF, Add 15g of ethylenediamine and 5g of dicyclohexylcarboimide and react at 120°C for 48h to obtain aminated graphene.

[0036] (2) Carboxylated graphene and aminated graphene were respectively dispersed in ethanol to obtain a slurry, and the concentration of carboxylated graphene and aminated graphene was 4 mg / mL.

[0037] (3) Heating the prepared carboxylated graphene and aminated graphene-graphene solution, and putting the graphene oxide solution into liquid nitrogen to cool after boiling until the solution is completely frozen, and then freezing it in situ Dry to obtain carboxylated graphene rolls and aminated graphene rolls.

[0038] (4) Two single-sided selective graphene oxide layers are coated on the base polyes...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com