Preparation method of moisture power generation device based on titanium dioxide/silicon dioxide

A silicon dioxide and titanium dioxide technology, which is applied to generators, electrical components, generators/motors, etc. that convert kinetic energy into electrical energy, can solve problems such as ecological damage and cost increase, and achieve low equipment requirements, simple preparation process, The effect of easy availability of materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

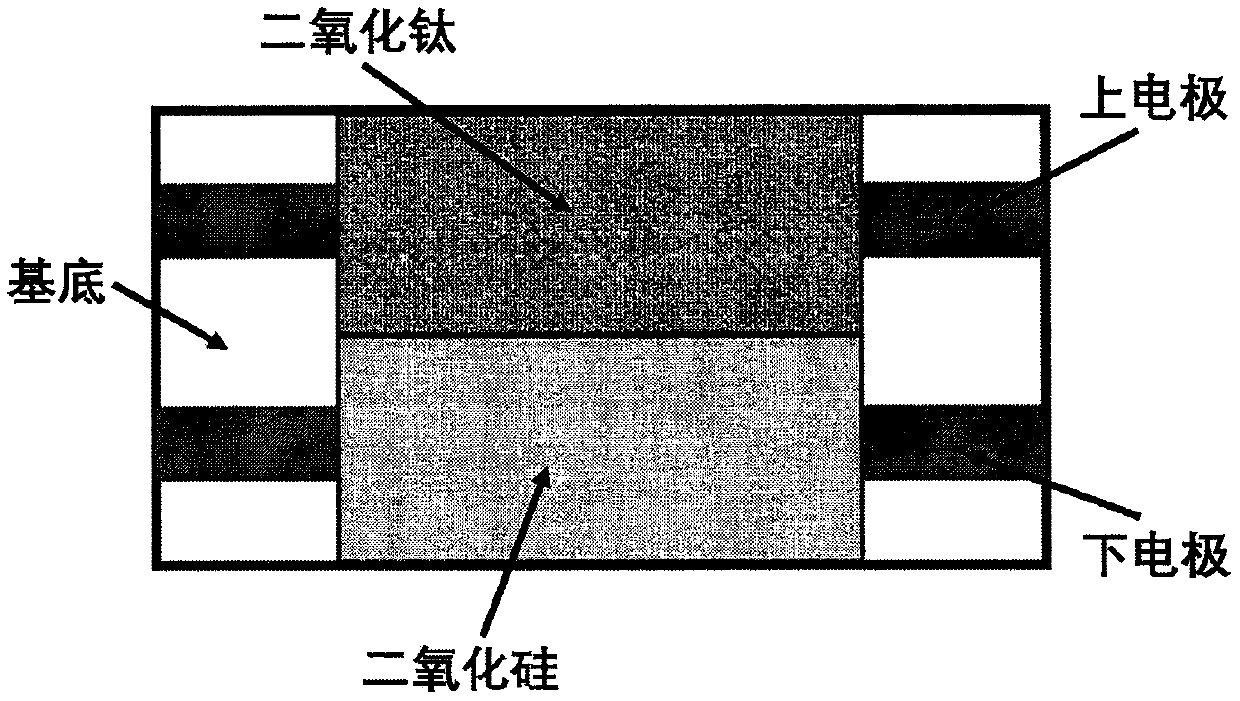

[0024] (1) Disperse silica nanofibers with an average diameter of 10nm and a length of 500nm and titania nanofibers with an average diameter of 10nm and a length of 500nm in ethanol. The masses of silica nanofibers and titania nanofibers are compared with ethanol. The mass ratio is the same as 7:3, and the slurry is obtained by ultrasonic for 20 minutes.

[0025] (2) Two carbon electrodes are coated on the base polyester resin film, the electrode width is 1 cm, the electrode length is 20 cm, and the distance between the upper electrode and the lower electrode is 4 cm.

[0026] (3) On the side of the substrate with the upper electrode and the lower electrode, the upper and lower ends are respectively coated with silica nanofiber slurry and titanium dioxide nanofiber slurry. After drying, an asymmetric moisture power generation device is obtained. The thickness of the coating It is 50μm.

[0027] (4) The device is placed in a humid environment with a humidity greater than 70%, and the...

Embodiment 2

[0029] (1) Disperse silica nanoparticles with an average particle size of 50nm and titanium dioxide nanoparticles with an average particle size of 50nm in ethanol, respectively. The mass ratio of silica to titania to ethanol is 7:3, ultrasonic 20min to obtain slurry.

[0030] (2) Two carbon electrodes are coated on the base polyester resin film, the electrode width is 1 cm, the electrode length is 20 cm, and the distance between the upper electrode and the lower electrode is 4 cm.

[0031] (3) On the side of the substrate with the upper electrode and the lower electrode, the upper and lower ends are respectively coated with silica slurry and titanium dioxide slurry, and after drying, an asymmetric moisture power generation device is obtained, and the thickness of the coating is 50 μm.

[0032] (4) The device is placed in a humid environment with a humidity greater than 70%, and the device generates voltage and current signals.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com