Large-ring-diameter silver nanoring and preparation method thereof

A technology of silver nanometer and ring diameter, which is applied in the direction of nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problem of low repeatability, small diameter of silver nanoring ring, unfavorable transparent electrodes and optical nanotechnology. Antenna and other issues, to achieve short response time, reduce production costs, and inhibit lateral growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

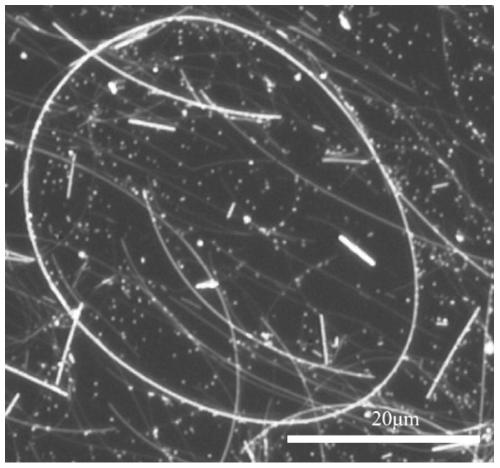

[0032] (1) Weigh 0.92g of polyvinylpyrrolidone with a weight-average molecular weight of 1,300,000 and add it to 70mL of glycerol, adjust the stirring speed of the constant temperature heating magnetic stirrer to 300rpm, stir and heat in the reaction vessel at 160°C until completely dissolved. Weigh 0.26g of tetramethylammonium chloride and dissolve it in 5mL of glycerol, weigh 0.08g of NaBr and dissolve it in 5mL of glycerol, then add it into the above reaction vessel, and stir for 15min. Mix 19mL glycerol with 1mL deionized water, weigh 0.49g AgNO 3 dissolve in it. After complete dissolution, turn off the stirring function of the constant temperature heating magnetic stirrer, and mix the above AgNO 3 The solution was added dropwise into the reaction vessel by a constant flow pump, and after 11 minutes of completion of the dropwise addition, the reaction vessel was closed, and the reaction was continued at 160° C. for 55 minutes to complete the reaction.

[0033] Transfer t...

Embodiment 2

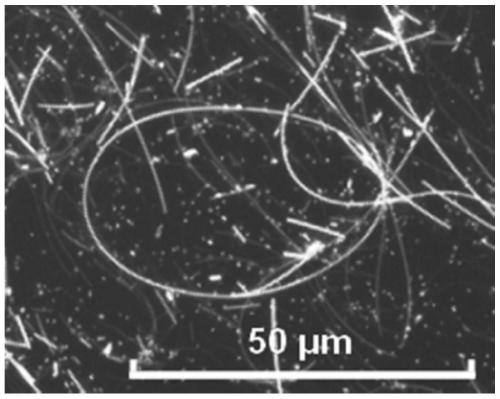

[0035] Weigh 0.92g of polyvinylpyrrolidone with a weight-average molecular weight of 1,300,000 and add it to 70mL of glycerol, adjust the stirring speed of the constant temperature heating magnetic stirrer to 300rpm, stir and heat in the reaction vessel at 160°C until completely dissolved; weigh tetramethyl chloride Dissolve 0.26g of ammonium in 5mL of glycerol, weigh 0.08g of NaBr and dissolve in 5mL of glycerol, then add to the above reaction vessel, stir for 15min; mix 19mL of glycerol with 1.5mL of ethylene glycol, weigh 0.49g of AgNO 3 dissolve in it. After complete dissolution, turn off the stirring function of the constant temperature heating magnetic stirrer, and mix the above AgNO 3 The solution was added dropwise into the reaction vessel by a constant flow pump, and after 11 minutes of completion of the dropwise addition, the reaction vessel was closed, and the reaction was continued at 160° C. for 55 minutes to complete the reaction. The centrifugal washing process...

Embodiment 3

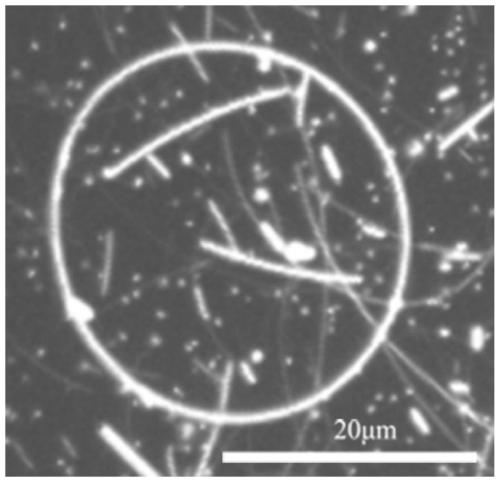

[0037] Weigh 1.38g of polyvinylpyrrolidone with a weight average molecular weight of 360,000 and add it to 70mL of glycerol, adjust the stirring speed of the constant temperature heating magnetic stirrer to 300rpm, stir and heat in the reaction vessel at 170°C until completely dissolved; weigh tetramethyl chloride Dissolve 0.26g of ammonium in 5mL of glycerol, weigh 0.08g of NaBr and dissolve in 5mL of glycerol, then add to the above reaction vessel, stir for 15min; mix 19mL of glycerol with 0.5mL of deionized water, weigh 0.49g of AgNO 3 dissolve in it. After complete dissolution, turn off the stirring function of the constant temperature heating magnetic stirrer, and mix the above AgNO 3The solution was added dropwise into the reaction vessel with a constant flow pump, and after 11 minutes of completion of the dropwise addition, the reaction vessel was closed, and the reaction was continued at 170° C. for 45 minutes to complete the reaction. The centrifugal washing process ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com