Method for preparing U3O8 from uranium-containing sodium carbonate solution

A technology of sodium carbonate and solution, which is applied in the field of uranium water smelting, can solve the problems of ammonium carbonate leaching and crystallization blockage, and achieve the effects of improving crystallization and impurity removal, avoiding bed blockage, and increasing uranium concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

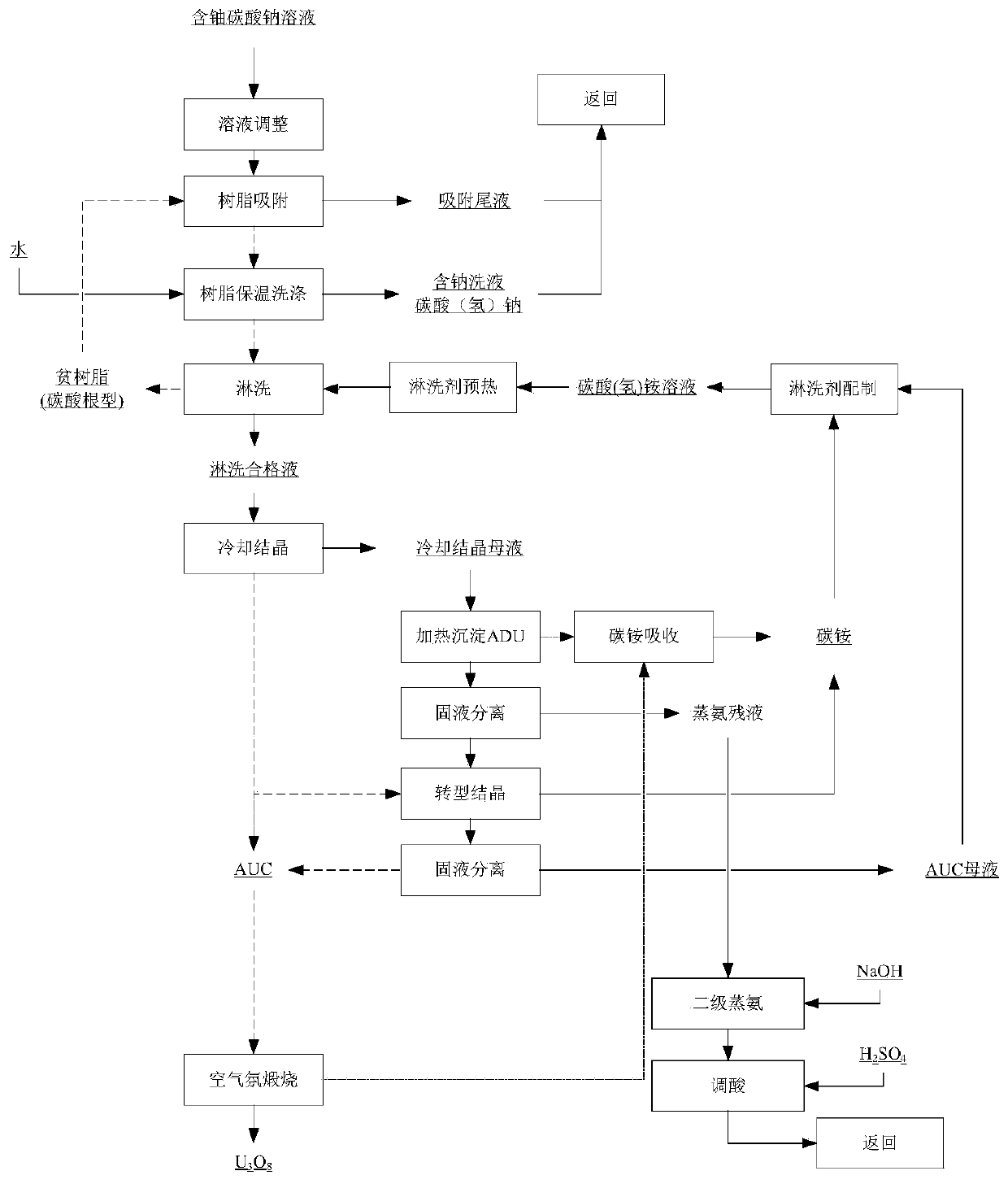

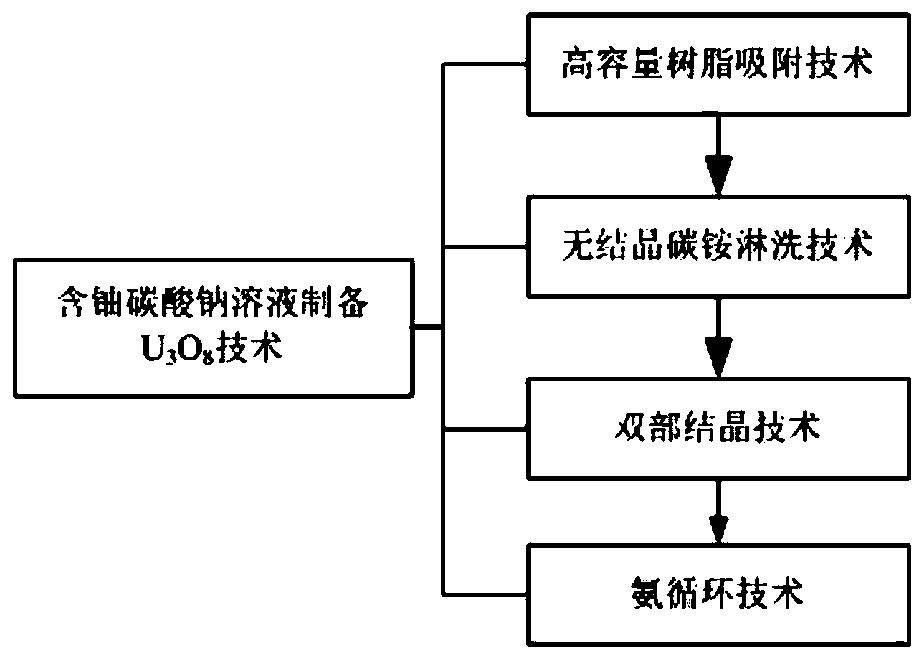

[0032] Such as image 3 As shown, a preparation of U from uranium-containing sodium carbonate solution 3 o 8 method, including the following steps:

[0033] Such as figure 1 Shown, step 1, sodium carbonate system high-capacity resin adsorption;

[0034] a) Adjust the uranium-containing carbonate solution by adding NaOH or H 2 SO 4 or CO 2 or NaHCO 3 or Na 2 CO 3 , or other acids and bases, adjust the pH value to 9-10.5, and increase the resin adsorption capacity under this system through pH adjustment.

[0035] b) Using strong basic resin to adsorb uranium in the adjusted solution at room temperature, washing the saturated resin with water, and returning the adsorption tail liquid and washing liquid.

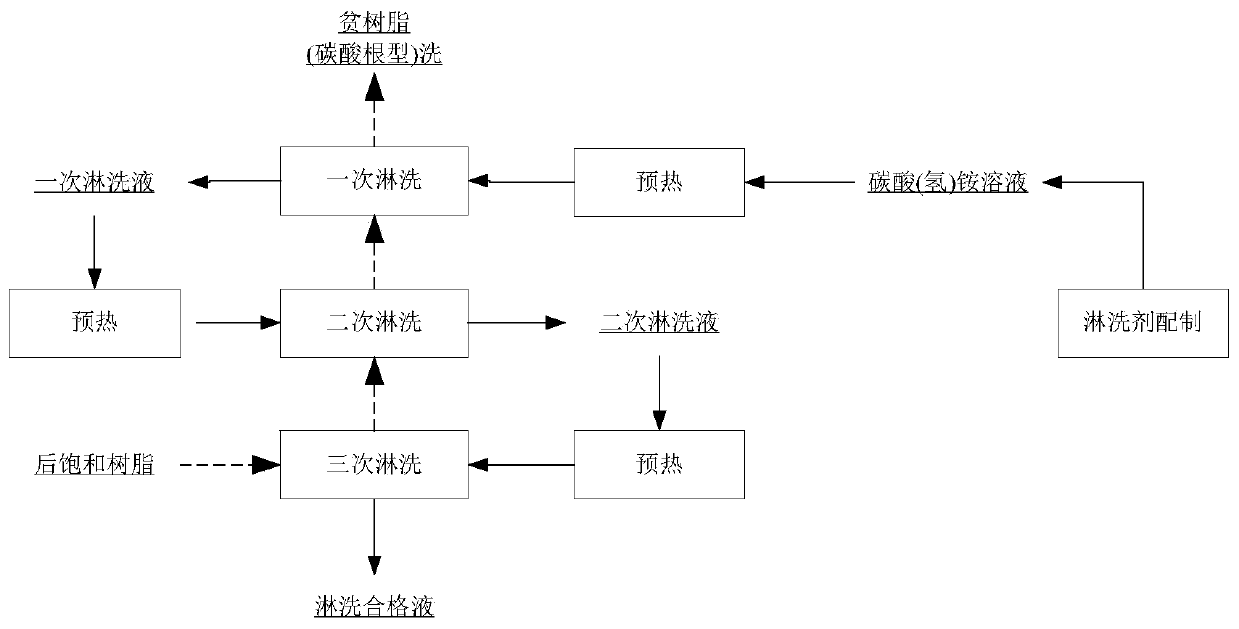

[0036] Such as figure 2 As shown, step 2, rinsing without crystalline ammonium bicarbonate;

[0037] Preheat the resin tower and keep it warm to keep the temperature stable at a certain value t1, which is between 35 and 50°C. Use hot ammonium bicarbonate rinse agen...

Embodiment 2

[0046] (1) A sodium carbonate solution containing uranium is the carbonate eluent of the resin. The uranium concentration is 4g / L, the total carbonate is 1mol / L, and the pH=9. Add NaOH to adjust the pH to 10, and use 201×7 resin to adsorb the adjusted solution. The resin capacity after adsorption is 54mg / ml. After the adsorption tail liquid is drained from the resin tower, the resin is washed with water, and the washing volume is 1BV , to obtain a saturated resin. The adsorption tail liquid and washing liquid are returned to the pre-adsorption process.

[0047] The saturated resin is rinsed with ammonium carbonate, and the cycle rinse process is applied 3 times. Before rinsing, the resin tower is heated and kept at 40°C, the pipeline is heated, and the eluent is heated to 40°C before feeding. The eluent concentration is 110g / LNH 4 HCO 3 +30g / L(NH 4 ) 2 CO 3. The eluting qualified liquid enters the cooling crystallization tank, and slowly stirs to cool down to room tem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com