Ecological toilet sewage treatment system and treatment process

A sewage treatment system and toilet technology, applied in water/sewage multistage treatment, water/sludge/sewage treatment, sedimentation treatment, etc. problems, to achieve the effects of low capital investment and operating costs, small footprint, and high processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

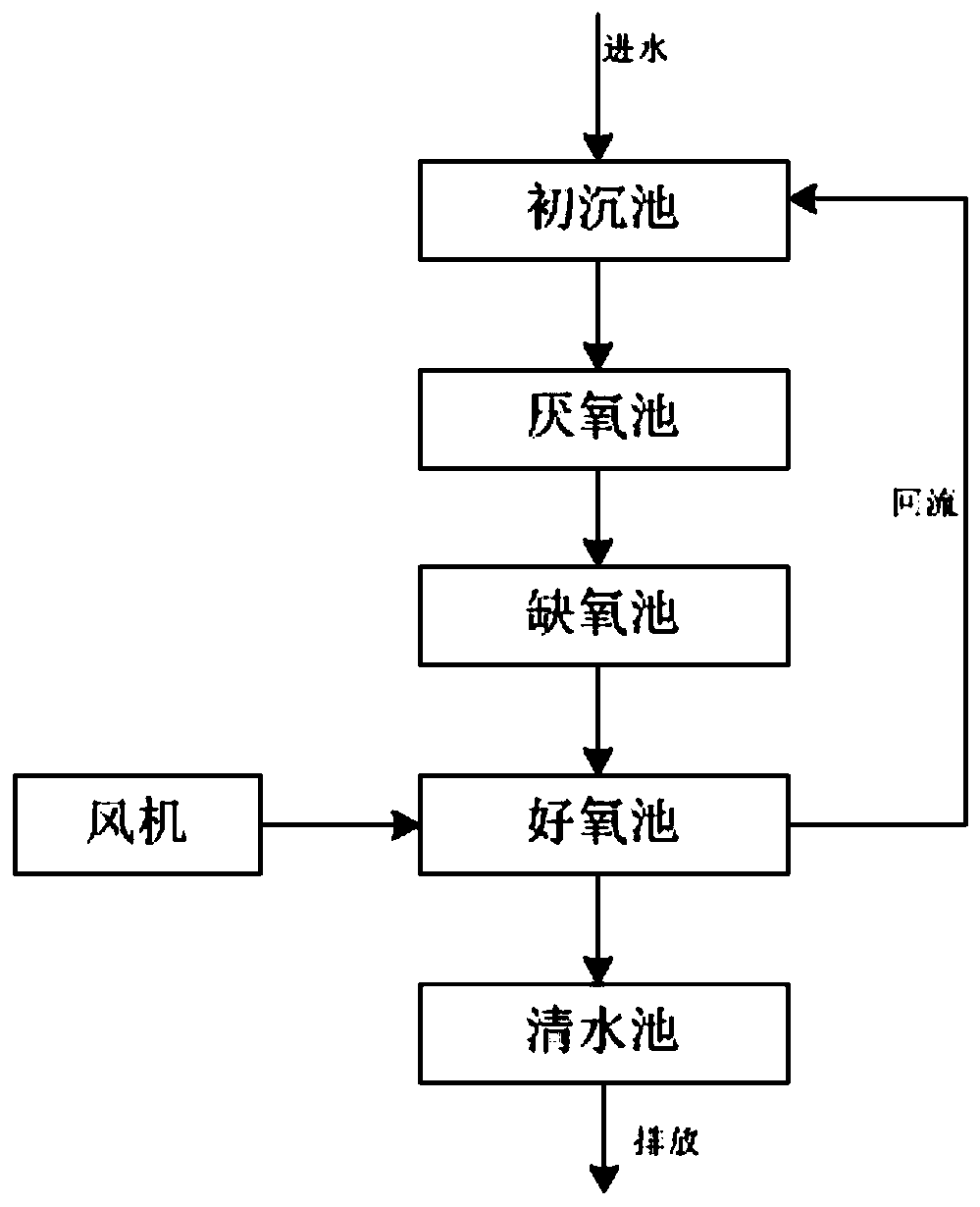

[0022] Such as figure 1 Shown, a kind of ecological toilet sewage treatment system comprises primary sedimentation pond, anaerobic pond, anoxic pond, aerobic pond, clean water pond, and the sewage that ecological toilet produces flows into in the primary sedimentation pond after pipeline collection; The settling tank is used to adjust the water volume and uniform water quality. In this embodiment, in order to prevent the floating matter in the primary settling tank from blocking the pipeline pump body and affecting the next treatment process, ensure the normal operation of the subsequent treatment structures and effectively reduce the processing load, the system is The long-term normal operation is guaranteed, and a grid ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com