A method for microfabrication of glass surface by using red nanosecond laser

A microfabrication and glass surface technology, which is applied in the field of microfabrication of glass surface with red nanosecond laser, can solve the problems of glass burn, microcrack, difficult to achieve precise microstructure processing, etc., and achieve the effect of reducing pulse energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

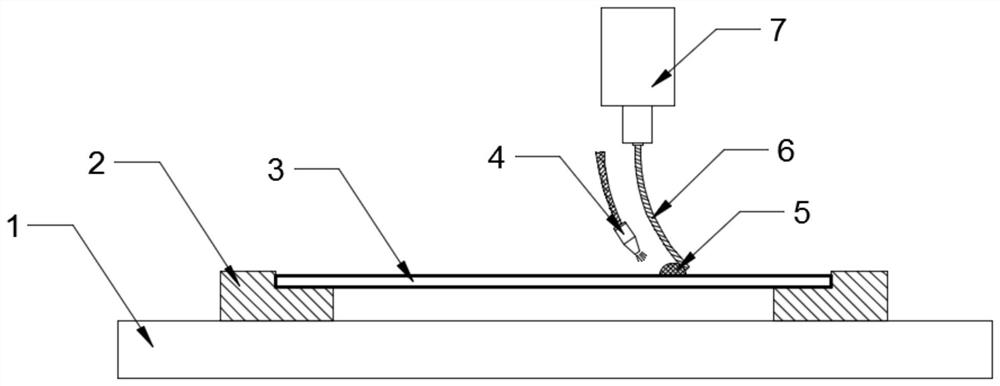

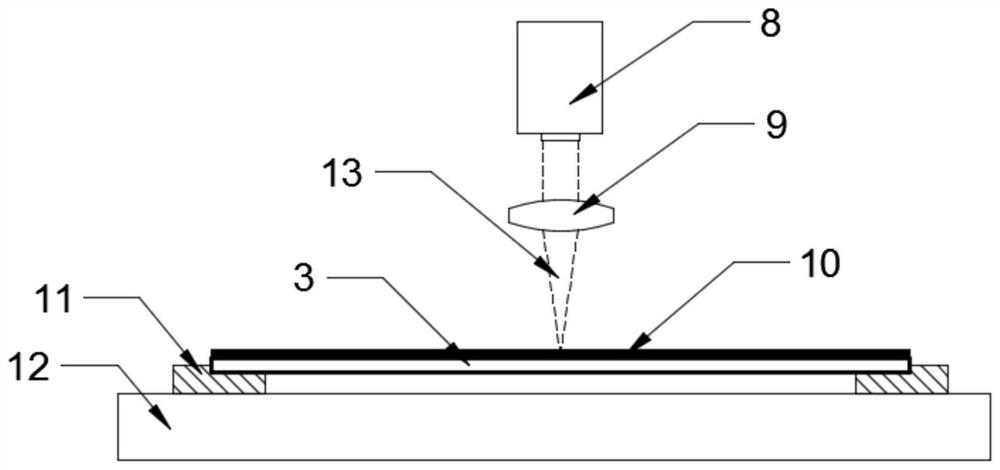

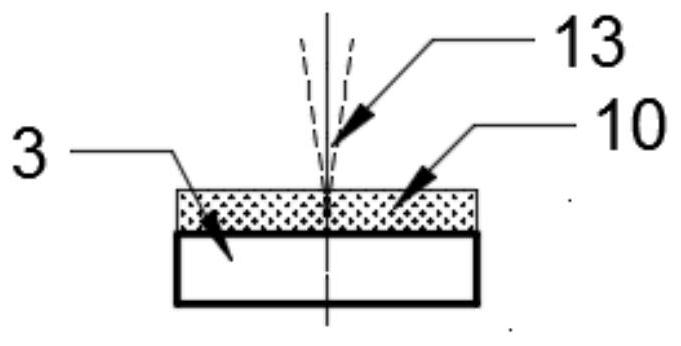

[0024] The present invention will be further described below with reference to the accompanying drawings. like Figure 1-3 As shown in the figure, a method for microfabricating a glass surface by using a red nanosecond laser includes the following steps:

[0025] Step A, the glass material surface is evenly coated with a layer of auxiliary materials 5;

[0026] Before laser processing, the auxiliary material 5 is selected, and the auxiliary material 5 is prepared into an aqueous solution with a solid content of 8% to 15%, and the glass surface is coated with the auxiliary material 5;

[0027] The glass sheet 3 is horizontally installed on the special fixture 2, and the special fixture 2 is fixedly installed on the two-dimensional precision worktable 1, so as to realize the two-dimensional movement of the special fixture 2 in the horizontal plane;

[0028] When coating, drop 0.4-0.6 mL of the auxiliary material 5 on the surface of the glass sheet 3, and drive the elastic elem...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com