Composite retarding and water reducing agent and preparation method thereof

A retarding water reducing agent and modification technology are applied in the field of composite retarding water reducing agent and its preparation to achieve the effects of good retardation, strength enhancement and water reduction rate improvement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

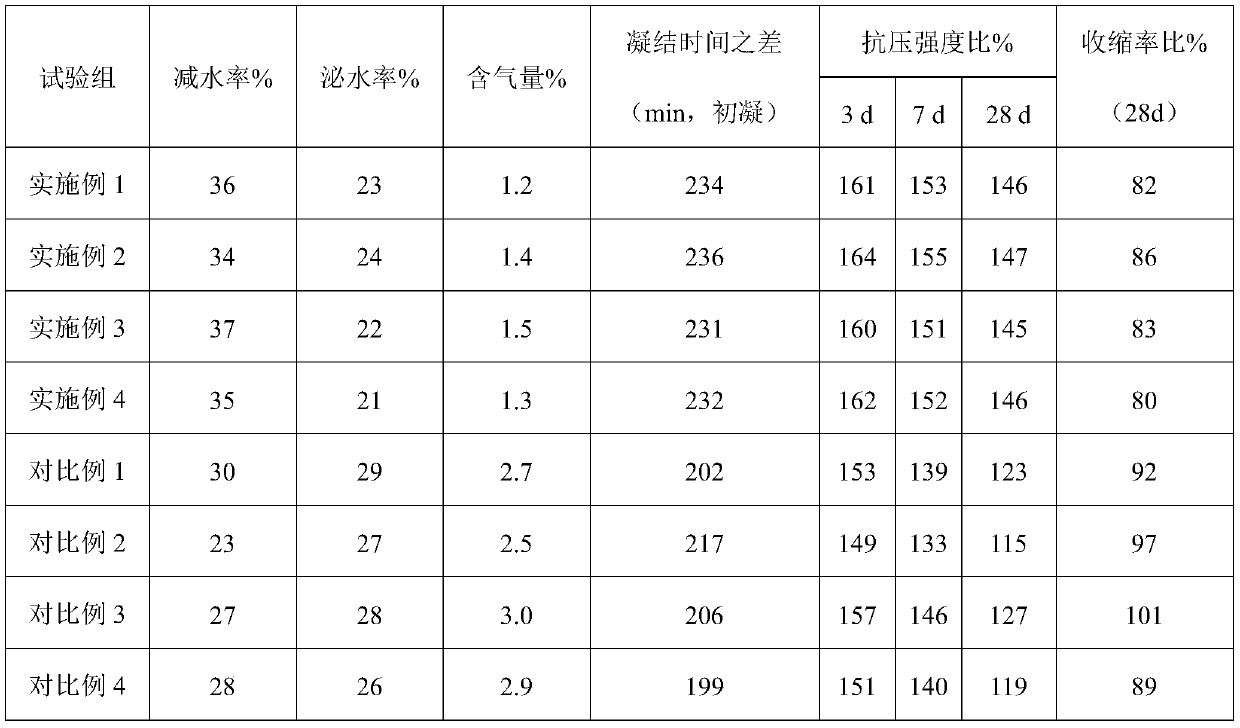

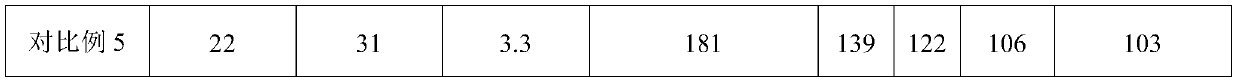

Examples

Embodiment 1

[0042] A composite retarding water reducer, in parts by weight, comprising the following components:

[0043] 100 parts of sodium lignosulfonate, 20 parts of fly ash, 10 parts of calcium silicate, 10 parts of sodium gluconate, 5 parts of silica gel powder, 10 parts of carboxymethyl cellulose (molecular weight 6400), 10 parts of sulfonated humic acid , 80 parts of modified polycarboxylates, 3 parts of citric acid;

[0044] The preparation method of described sulfonated humic acid is:

[0045] Take humic acid (HA), add distilled water, then add potassium hydroxide to dissolve, add NaHSO twice the mass of humic acid 3 The sulfonating agent is reacted at 40°C. After the reaction, the pH value is adjusted to 3, filtered, dried and pulverized to obtain sulfonated humic acid.

[0046] The preparation method of described modified polycarboxylate is:

[0047] Take 1 part of 2-acrylamido-2-methylpropanesulfonic acid and add 15 times of water, add 3 parts of maleic anhydride, add 0.05...

Embodiment 2

[0052] A composite retarding water reducer, in parts by weight, comprising the following components:

[0053]200 parts of sodium lignosulfonate, 10 parts of fly ash, 20 parts of calcium silicate, 5 parts of sodium gluconate, 10 parts of silica gel powder, 15 parts of carboxymethyl cellulose (molecular weight 6000), 5 parts of sulfonated humic acid , 50 parts of modified polycarboxylates, 8 parts of citric acid;

[0054] The preparation method of described sulfonated humic acid is:

[0055] Take humic acid (HA), add distilled water, then add potassium hydroxide to dissolve, add Na 2 SO 3 The sulfonating agent reacts at 60°C. After the reaction, adjust the pH value to 5, filter with suction, dry, and pulverize to obtain sulfonated humic acid.

[0056] The preparation method of described modified polycarboxylate is:

[0057] Take 1 part of 2-acrylamido-2-methylpropanesulfonic acid and add 30 times of water, add 5 parts of maleic anhydride, add 0.08% (with 2-acrylamido-2-methy...

Embodiment 3

[0062] A composite retarding water reducer, in parts by weight, comprising the following components:

[0063] 50 parts of sodium lignosulfonate, 50 parts of fly ash, 50 parts of calcium silicate, 10 parts of sodium gluconate, 20 parts of silica gel powder, 20 parts of carboxymethyl cellulose (molecular weight 7000), 1 part of sulfonated humic acid , 10 parts of modified polycarboxylate, 1 part of citric acid;

[0064] The preparation method of described sulfonated humic acid is:

[0065] Take humic acid (HA), add distilled water, then add potassium hydroxide to dissolve, add NaHSO which is 3 times the mass of humic acid 3 The sulfonating agent is reacted at 50°C. After the reaction, the pH value is adjusted to 4, filtered, dried and pulverized to obtain sulfonated humic acid.

[0066] The preparation method of described modified polycarboxylate is:

[0067] Take 1 part of 2-acrylamido-2-methylpropanesulfonic acid and add 20 times of water, add 4 parts of maleic anhydride, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com