Ardealite ecological brick, preparation method and slope fixing method

A technology of phosphogypsum and ecological bricks, applied in the field of phosphogypsum, can solve the problems of high production cost, inability to produce building gypsum powder and its products, and limit the market prospect of phosphogypsum building material utilization, and achieve high comprehensive utilization rate , to achieve sustainable development, good ecological and economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

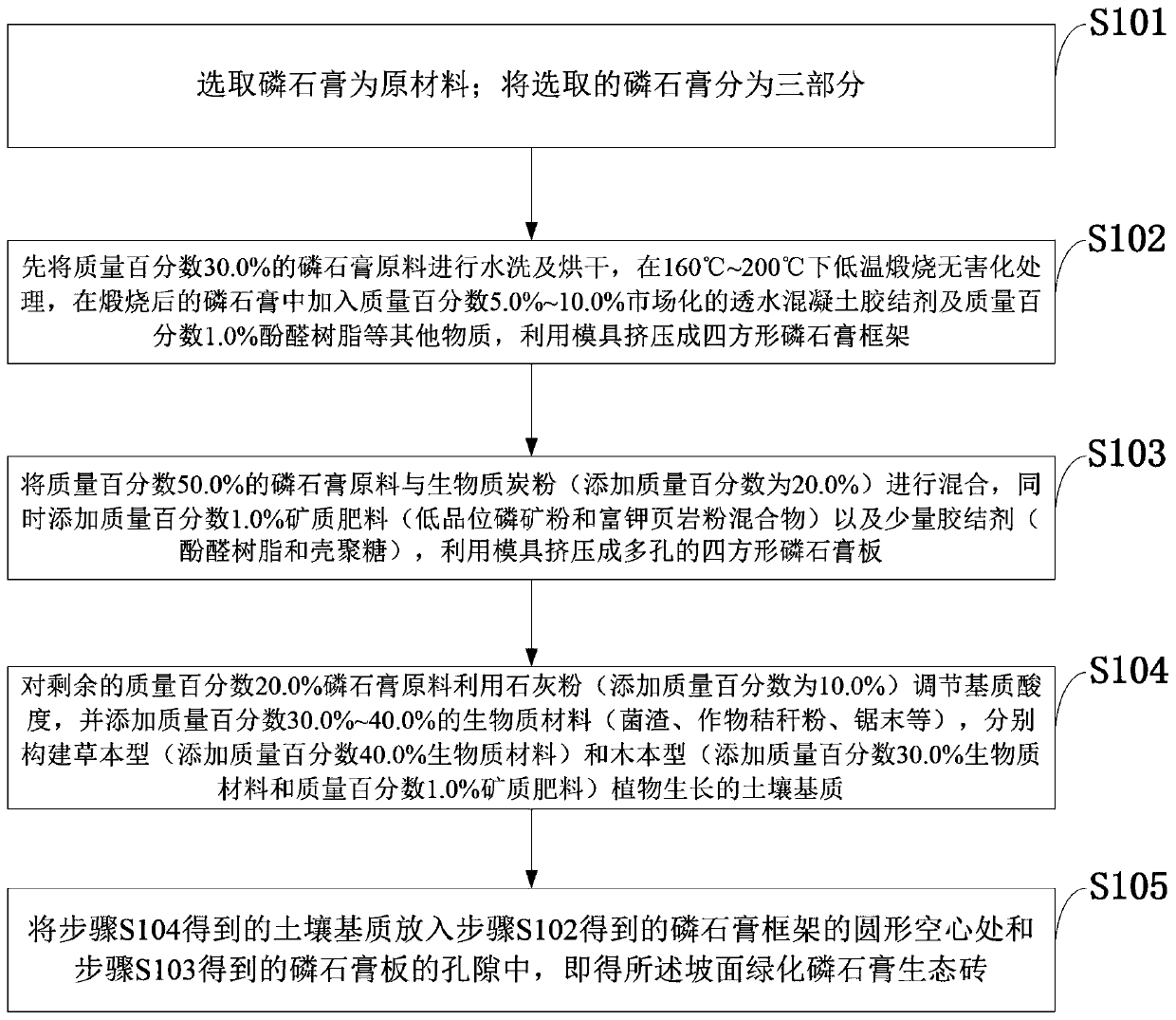

[0030] Such as figure 1 Shown, the preparation method of the phosphogypsum ecological brick that the embodiment of the present invention provides comprises:

[0031] S101: selecting phosphogypsum as a raw material; dividing the selected phosphogypsum into three parts.

[0032] S102: Wash and dry the phosphogypsum raw material with a mass percentage of 30.0% first, then calcinate it at a low temperature of 160°C to 200°C for harmless treatment, and add 5.0% to 10.0% by mass of commercialized phosphogypsum to the calcined phosphogypsum Permeable concrete binder and 1.0% by mass percentage of phenolic resin and other substances are extruded into a square phosphogypsum frame by a mold;

[0033] S103: Mix 50.0% by mass phosphogypsum raw material with biochar powder (20.0% by mass), and add 1.0% by mass of mineral fertilizer (a mixture of low-grade phosphate rock powder and potassium-rich shale powder) and A small amount of cement (phenolic resin and chitosan) is extruded into a p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com