Method for preparing de-chlorinating agent by grafting reaction of chitosan oligosaccharide and benzotriazole compound and de-chlorinating agent prepared thereby

A technology of benzotriazoles and chitosan oligosaccharides, which is applied in chemical instruments and methods, water pollutants, water/sludge/sewage treatment, etc. and other problems, to achieve the obvious effect of dechlorination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

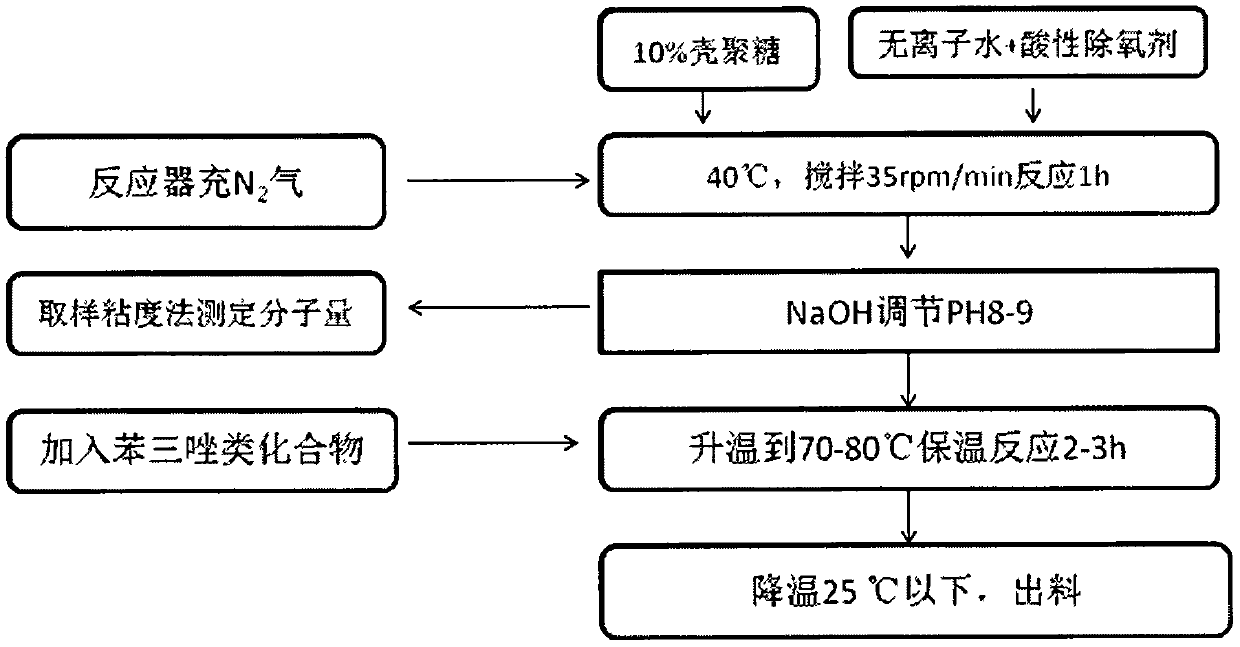

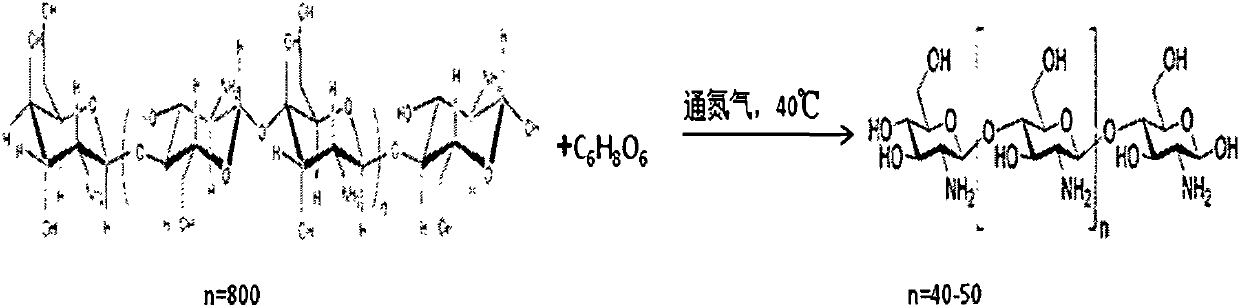

[0021] 1) Preparation of chitosan oligosaccharides: Under the protection of inert gas, mix chitosan, deionized water, and acidic antioxidant at low speed, and hydrolyze at 35-40°C for 1h-1.5h to generate M=4000-5000Da , the chitosan oligosaccharide of n=4~50 repeating units, wherein deionized water, chitosan, acidic antioxidant are according to mass ratio, and deionized water: chitosan: acidic antioxidant is 8~10:1 ~2:0.2~0.3,

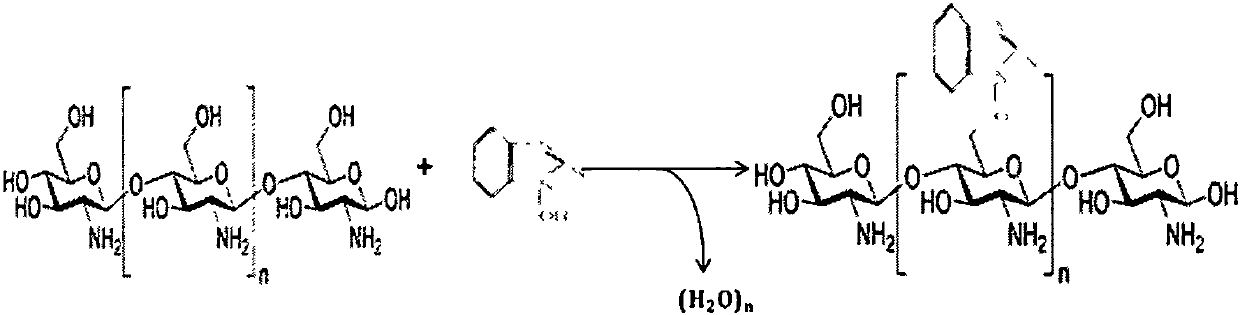

[0022] 2) Immediately after the completion of the hydrolysis, use NaOH to adjust the pH value to 8-9, add benzotriazole compounds with 40% chitosan mass, stir at a medium speed, heat up to 70-80°C for grafting reaction, keep the temperature for 2 hours, and control for 2 hours- After 2.5 hours, the temperature was lowered to 25°C, and a colorless or light yellow viscous finished product was obtained, which is a dechlorination agent.

[0023] The acidic antioxidant is C 6 h 8 o 6 、C 6 h 8 o 6 Sodium salt and C 6 h 8 o 6 One or more of the pota...

Embodiment 1

[0032] (1) Pass N into the 250ml reactor 2 Gas five minutes, add deionized water 88ml, acidic antioxidant C 6 h 8 o 6 2 grams, 10 grams of chitosan, stirring at a low speed, the stirring speed is 35rpm / min, turn on the condenser, heat up to 35-40°C, keep the temperature for 1 hour, and complete the hydrolysis reaction. At this time, chitosan is hydrolyzed into oligomeric chitosan, and the molecular weight measured by viscosity method should be 4000-5000 Da, and n=40-50 repeating units. Reaction formula:

[0033]

[0034] (2) Immediately after the completion of the hydrolysis, adjust the pH value to 8-9 with NaOH, add 4 grams (40% of chitosan quality) of 1-hydroxybenzotriazole, stir to 80rpm / min, and heat up to 70-80 ℃, reacted for 2h, and completed. Control the annealing within 2h to 2.5h and cool down to 25°C before discharging.

[0035] Reaction formula:

[0036]

Embodiment 2

[0038] (1) Pass N into the 500ml reactor 2 Gas for 10 minutes, add 175ml of deionized water, acidic antioxidant C 6 h 8 o 6 、C 6 h 8 o 6 2.5 grams each of sodium salt, 20 grams of chitosan, stirred at a low speed, the stirring speed is 35 rpm / min, the condenser is turned on, the temperature is raised to 40°C, and the reaction is kept for 1.5 hours to complete the hydrolysis reaction. At this time, chitosan is hydrolyzed into oligomeric chitosan, and the molecular weight measured by viscosity method should be 4000-5000 Da, and n=40-50 repeating units.

[0039](2) Immediately after the completion of the hydrolysis, use NaOH to adjust the pH value to 8-9, add 3 g of benzotriazole and 5 g of 1-hydroxymethyl benzotriazole, stir and increase to 80 rpm / min, and heat up to 75-80 °C , heat preservation reaction for 2 hours, after the reaction is completed, anneal and cool down to 25 degrees Celsius within 2 hours to 2.5 hours before discharging.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com