Catalyst for catalyzing incineration of vinyl chloride polymerization moisture-containing tail gas and preparation method thereof

A vinyl chloride polymerization and catalytic incineration technology, applied in the direction of catalyst activation/preparation, physical/chemical process catalysts, combustion methods, etc., to prevent loss, avoid catalyst deactivation by alkali poisoning, and improve anti-poisoning ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

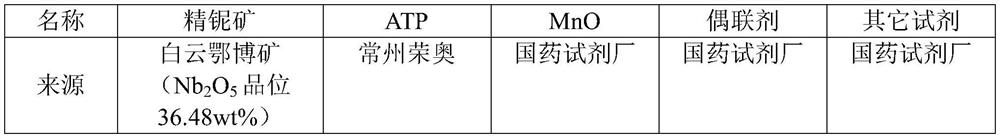

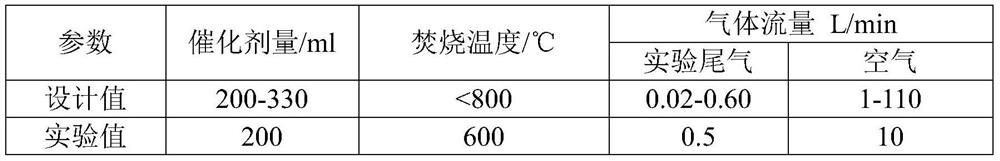

[0044] (1) Preparation of active component doping precursor: take 100g of niobium concentrate, add a concentration of 40wt% hydrofluoric acid solution to dissolve, add a concentration of 40wt% potassium fluoride solution to the reacted solution, and control the niobium concentrate: The mass ratio of hydrofluoric acid: potassium fluoride is 1:3:0.8, and the reaction is carried out at room temperature for 60 minutes to obtain the doping component precursor K 2 [NbOF 5 ] solution.

[0045] (2) Preparation of doping active components: Take 10g active component MnO and dissolve in 300g precursor solution, then add NH 4 OH to control pH = 8, fully stirred for 20 minutes and mixed to obtain the doping active component.

[0046] (3) Preparation and modified carrier: refer to the general method for preparing ATP powder in Example 1 (step 2-3) of patent CN 102794169 B, and sieve out 200-300 mesh ATP powder. Weigh 100g powder and put it into 1L modified solvent (the volume ratio of ea...

Embodiment 2

[0052] (1) Preparation of active component doping precursor: control the mass ratio of refined niobium ore: hydrofluoric acid: potassium fluoride to be 1:3:1, and other conditions are the same as in Example 1.

[0053] (2) Preparation of doping active components: Same as Example 1.

[0054] (3) Preparation and modified carrier: KH-550 was selected as the silane coupling agent, and other conditions were the same as in Example 1.

[0055] (4) load active component: with embodiment 1.

[0056] Catalytic incineration tail gas effect is shown in Table 5 below:

[0057] Table 5 Composition of chlorine-containing tail gas

[0058] Content / Ingredient vinyl chloride water carbon dioxide carbon monoxide Chloromethane Nitrogen Content before treatment (wt) 62% 1.8% 15% 6% 0.2% 15% Content after treatment (wt) 27ppm 2% 83% 0 8ppm 15%

Embodiment 3

[0060] (1) Preparation of active component doping precursor: take 100g of niobium concentrate, add a concentration of 40wt% hydrofluoric acid solution to dissolve, add a concentration of 40wt% potassium fluoride solution to the reacted solution, and control the niobium concentrate: The mass ratio of hydrofluoric acid: potassium fluoride is 1:4:1, and the reaction is carried out at room temperature for 60 minutes to obtain the doping component precursor K 2 [NbOF 5 ] solution.

[0061] (2) Preparation of doped active components: Dissolve 20g of active component MnO in 300g of precursor solution, and then add excess NH 4 OH to control pH = 9, fully stirred for 20 minutes and mixed to obtain the doping active component.

[0062] (3) Preparation and modified carrier: refer to the general method for preparing clavgrass powder in Example 1 (step 2-3) of patent CN 102794169B, and obtain the sieve component of ATP powder with 200 mesh to 300 mesh. Weigh 100g of powder and put it in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com