Method for improving performance of Sn matrix Babbitt alloy

A tin-based babbitt alloy and performance technology, applied in the field of bearing bush wear resistance, can solve the problems of bearing bush falling off, bearing scrap, babbitt alloy wear resistance, poor hardness and bonding strength, etc., to achieve the effect of improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

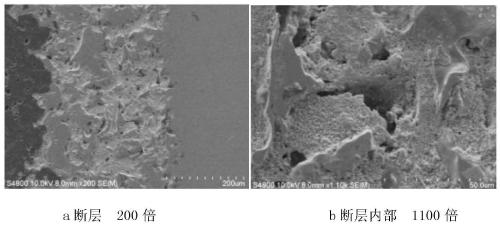

[0026] Such as Figure 1-4 As shown, the present invention provides a kind of technical scheme: a kind of method for improving the performance of tin-based babbitt alloy, comprises the steps:

[0027] S1, take an appropriate amount of tin-based Babbitt alloy powder, metallic cobalt Co powder and tungsten carbide WC powder, wherein metallic cobalt Co powder accounts for 8-20% of the weight of tin-based Babbitt alloy powder; 4%-10% of alloy powder weight;

[0028] S2. Add tin-based Babbitt alloy powder, metal cobalt Co powder and tungsten carbide WC powder into the mixer for mixing, so that tin-based Babbitt alloy powder, metal cobalt Co powder and tungsten carbide WC powder are fully mixed 6-8 hours, get spray powder;

[0029] S3. Add the mixed spray powder into the plasma spray equipment, and use the plasma spray equipment to evenly spray the spray powder on the H62 brass surface with a size of 25*50*2-3mm;

[0030] Among them, the model of the plasma spraying equipment is ...

Embodiment 2

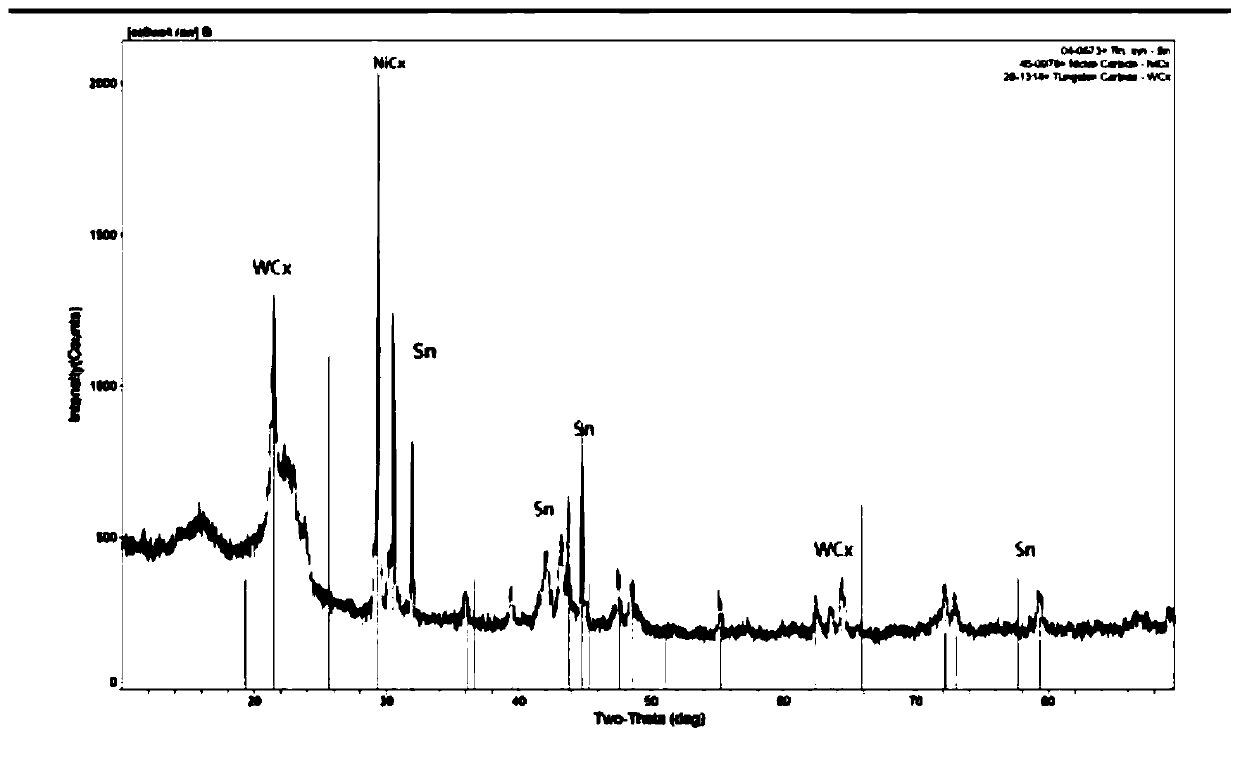

[0043] Such as figure 1 As shown, the present invention provides a kind of technical scheme: a kind of method for improving the performance of tin-based babbitt alloy, comprises the steps:

[0044] S1, get an appropriate amount of tin-based Babbitt alloy powder, metal cobalt Co powder and tungsten carbide WC powder, wherein metal cobalt Co powder accounts for 8% of the tin-based Babbitt alloy powder weight; tungsten carbide WC powder accounts for tin-based Babbitt alloy powder 4% by weight;

[0045] S2. Add tin-based Babbitt alloy powder, metal cobalt Co powder and tungsten carbide WC powder into the mixer for mixing, so that tin-based Babbitt alloy powder, metal cobalt Co powder and tungsten carbide WC powder are fully mixed 6-8 hours, get spray powder;

[0046] S3. Add the mixed spray powder into the plasma spray equipment, and use the plasma spray equipment to evenly spray the spray powder on the H62 brass surface with a size of 25*50*2-3mm;

[0047] Among them, the mode...

Embodiment 3

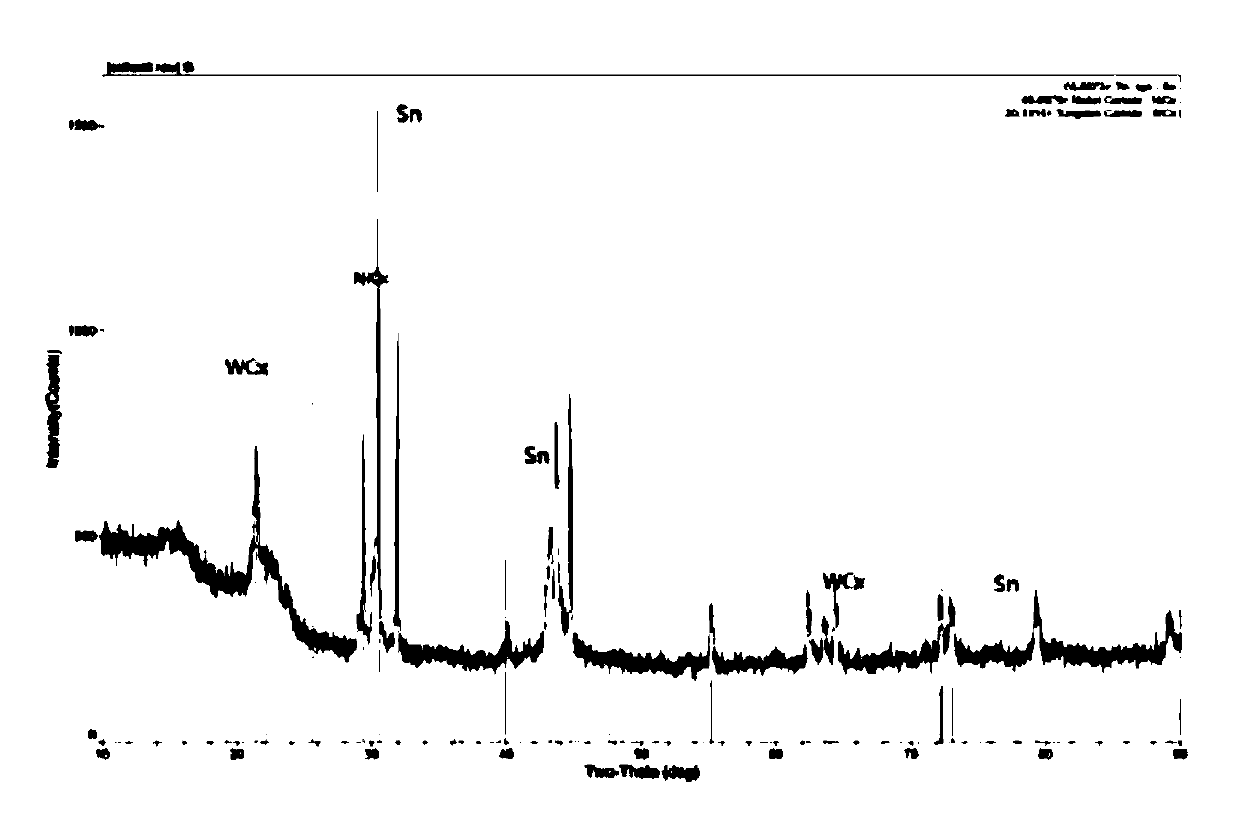

[0056] Such as figure 2 As shown, the present invention provides a kind of technical scheme: a kind of method for improving the performance of tin-based babbitt alloy, comprises the steps:

[0057] S1, get an appropriate amount of tin-based Babbitt alloy powder, metal cobalt Co powder and tungsten carbide WC powder, wherein metal cobalt Co powder accounts for 8% of the tin-based Babbitt alloy powder weight; tungsten carbide WC powder accounts for tin-based Babbitt alloy powder 8% by weight;

[0058] S2. Add tin-based Babbitt alloy powder, metal cobalt Co powder and tungsten carbide WC powder into the mixer for mixing, so that tin-based Babbitt alloy powder, metal cobalt Co powder and tungsten carbide WC powder are fully mixed 6-8 hours, get spray powder;

[0059] S3. Add the mixed spray powder into the plasma spray equipment, and use the plasma spray equipment to evenly spray the spray powder on the H62 brass surface with a size of 25*50*2-3mm;

[0060] Among them, the mod...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Microhardness | aaaaa | aaaaa |

| Wear rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com