Preparation method of ferroelectric film, ferroelectric memory and preparation method of ferroelectric memory

A ferroelectric memory and ferroelectric thin film technology, applied in the field of ferroelectric thin film preparation, ferroelectric memory and its preparation, can solve the problems of difficult control of ferroelectric thin film doping concentration, poor uniformity of thin film doping, etc. Ensure doping uniformity, reduce process steps, and improve the effect of uniform doping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] The embodiment of the present application discloses a method for preparing a ferroelectric thin film. The method includes:

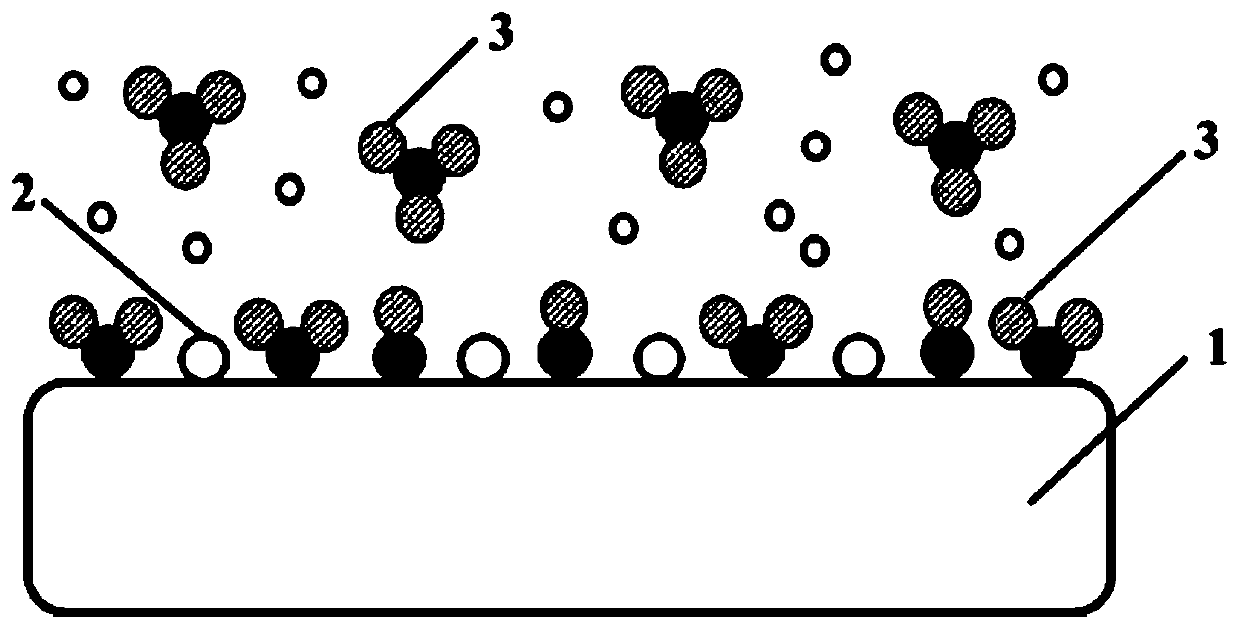

[0037] The main element source is used as the reaction precursor to carry out atomic layer deposition, and the main element is deposited on the surface of the substrate; the precursor of the main element source is injected into the chamber with a set chamber temperature for surface reaction, and the deposition time is controlled to absorb the substrate. Most of the free bonding sites on the bottom surface;

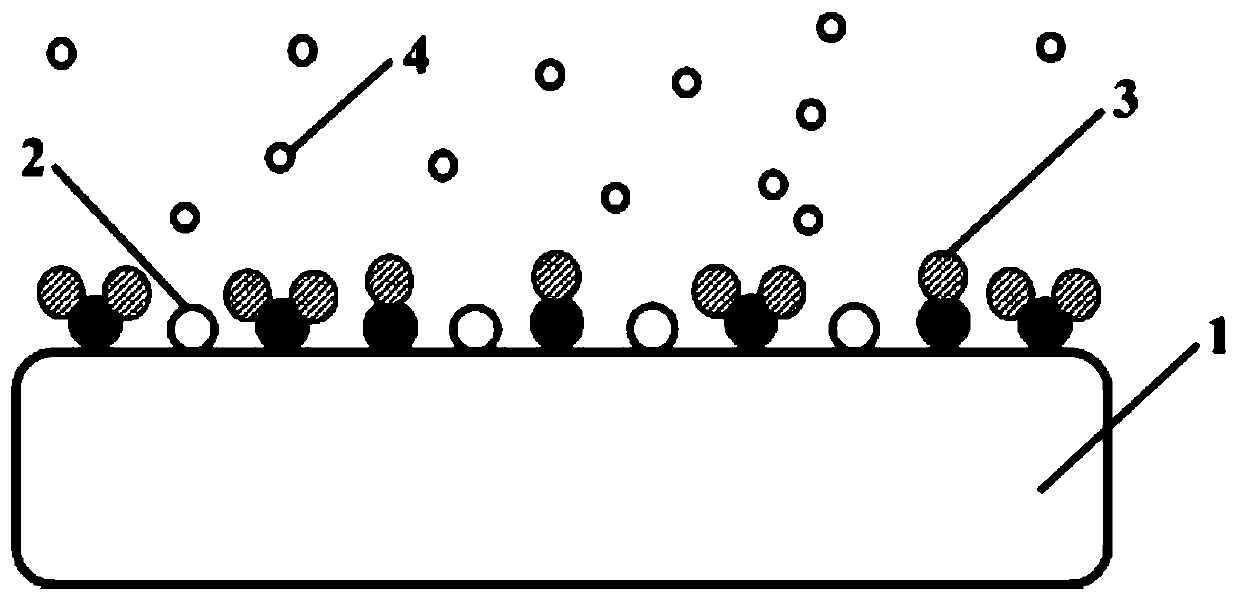

[0038] Use inert gas as purge gas to carry out purging; through purging, remove excess reactants and by-products;

[0039] Atomic layer deposition is carried out using the dopant element source as a reactive precursor, so that the dopant element adsorbs the remaining free bonding points on the surface of the substrate;

[0040] Use inert gas as purge gas for purge removal;

[0041] Oxidation treatment with oxidizing gas;

[0042] Use inert...

Embodiment 1

[0056] The main element precursor 3 is a hafnium source precursor, specifically selected from tetramethylethylamino hafnium (99.9% in purity), and the dopant element precursor 5 is an aluminum source precursor, specifically selected from trimethylaluminum (TMA, with a purity of 99.9%) , O 3 As the oxygen source precursor, Ar is used as the carrier gas and purge gas. Al-doped hafnium oxide-based ferroelectric thin films with low doping concentration were prepared by an improved atomic layer deposition process, and the target doping concentration was 2%. Include the following steps:

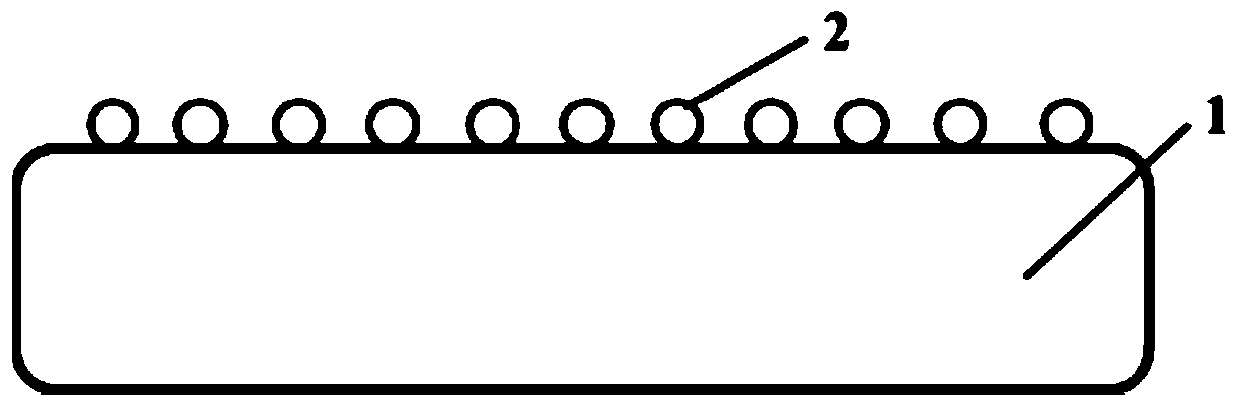

[0057] Prepare a clean and tidy substrate 1 (refer to figure 1 ) into the chamber of the atomic layer deposition instrument.

[0058] The temperature of the chamber is preferably set to 280° C. and kept at a constant temperature, and then argon gas is introduced into the reaction chamber for 30 seconds while the pressure in the reaction chamber is controlled to be 180 mtorr. The heating tempera...

Embodiment 2

[0066] Select tetra-tert-butyl hafnium (purity is 99.9%) as hafnium source precursor, three (dimethylamino) silane (3DMAS, purity is 99.9%) is silicon source precursor, O 3 As the oxygen source precursor, Ar is used as the carrier gas and purge gas. A silicon-doped hafnium oxide-based ferroelectric thin film with low doping concentration was prepared by an improved atomic layer deposition process. The target doping concentration is 3%. Include the following steps:

[0067] Prepare a clean and tidy substrate (refer to figure 1 ) into the chamber of the atomic layer deposition instrument.

[0068] The temperature of the chamber is preferably set to 280° C. and kept at a constant temperature, and then argon gas is introduced into the reaction chamber for 30 seconds while the pressure in the reaction chamber is controlled to be 180 mtorr. The heating temperature of the reaction precursor is 75-80°C. Under this condition, the hafnium source precursor tetra-tert-butyl hafnium is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com