Anti-cracking type floor and construction method thereof

A construction method and anti-cracking technology, applied in primers, epoxy resin coatings, polyester coatings, etc., can solve problems such as poor compression resistance, easy cracking of the floor, and no wear resistance, and achieve long service life, The effect of short construction period and reduced possibility of cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

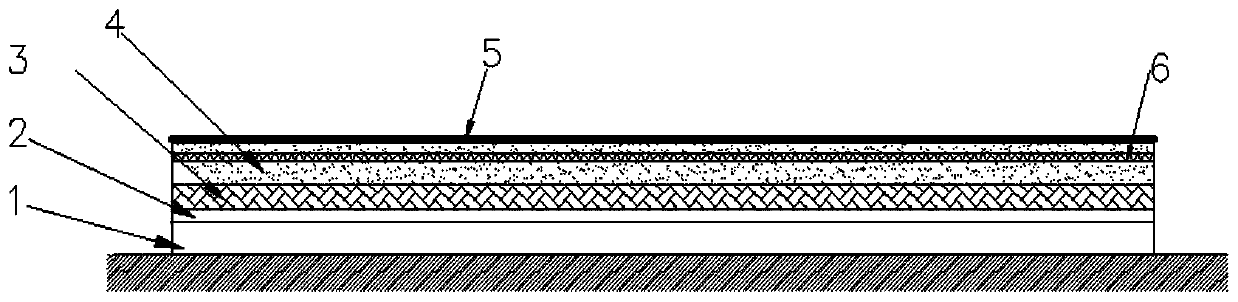

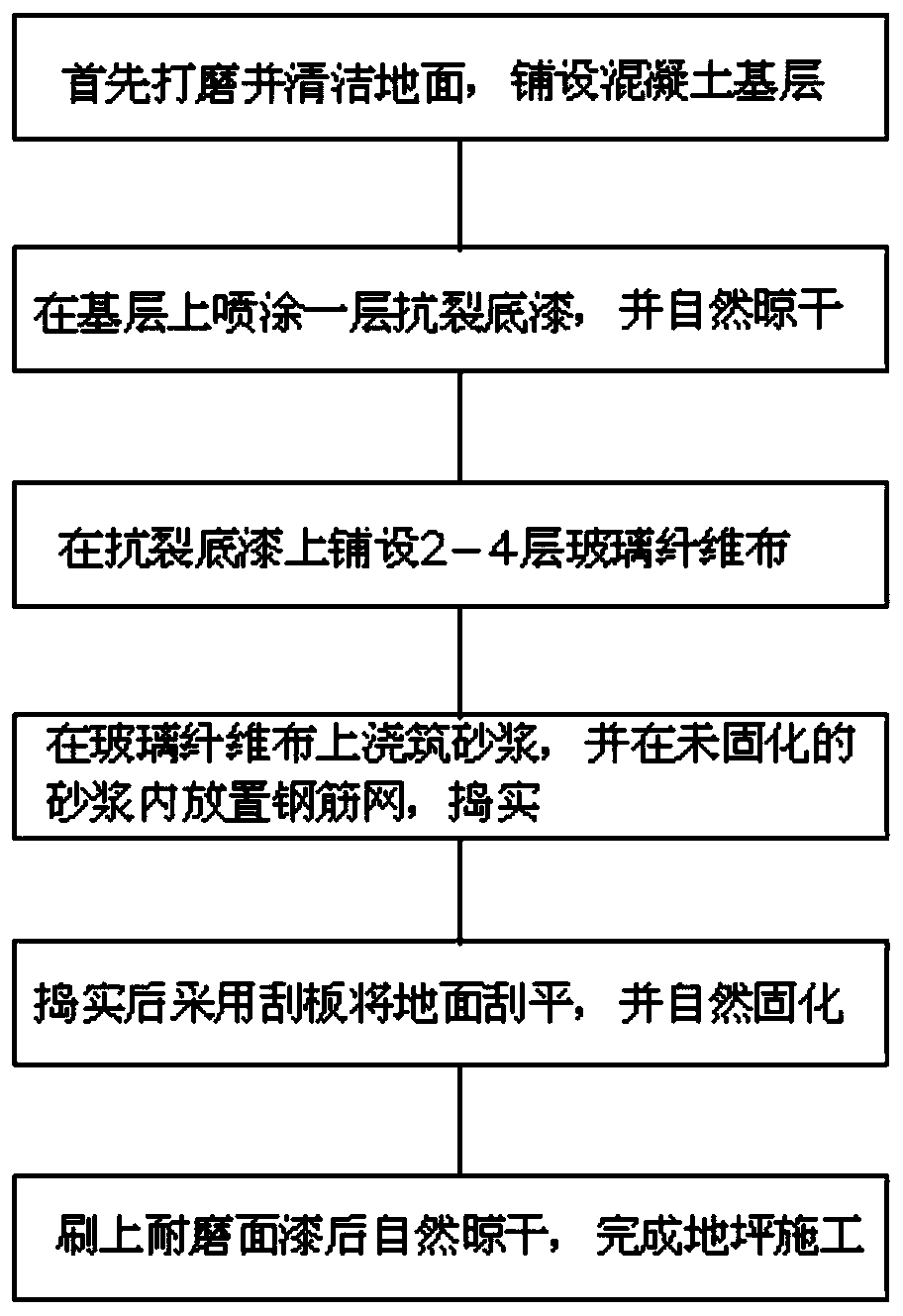

[0042] A construction method of an anti-cracking type floor is carried out as follows:

[0043] A. First grind and clean the ground, and then lay a layer of concrete to form a concrete base;

[0044] B. Spray anti-crack primer on the concrete base and let it dry naturally;

[0045] C. Lay 2 layers of glass fiber cloth on the dried anti-crack primer;

[0046] D. Lay mortar on the glass fiber cloth, embed steel mesh in the uncured mortar, and use a vibrator to compact it;

[0047] E. The tamped mortar is scraped off with a scraper and cured naturally;

[0048] F. Finally, brush the wear-resistant topcoat on the surface of the mortar. After one layer, wait for natural drying and then paint another layer, and then dry it naturally and then paint another layer. Brush three times in total.

[0049] In the present embodiment, in terms of mass percentage, the anti-crack primer in step B consists of 40% castor oil short oil alkyd resin, 20% tertiary vinegar resin, 10% calcium zircon...

Embodiment 2

[0053] A construction method of an anti-cracking type floor is carried out as follows:

[0054] A. First grind and clean the ground, and then lay a layer of concrete to form a concrete base;

[0055] B. Spray anti-crack primer on the concrete base and let it dry naturally;

[0056] C. Lay 4 layers of glass fiber cloth on the dried anti-crack primer;

[0057]D. Lay mortar on the glass fiber cloth, embed steel mesh in the uncured mortar, and use a vibrator to compact it;

[0058] E. The tamped mortar is scraped off with a scraper and cured naturally;

[0059] F. Finally, brush the wear-resistant topcoat on the surface of the mortar. After one layer, wait for natural drying and then paint another layer, and then dry it naturally and then paint another layer. Brush three times in total.

[0060] In the present embodiment, in terms of mass percentage, the anti-crack primer in step B consists of 40% castor oil short oil alkyd resin, 20% tertiary vinegar resin, 10% calcium zircona...

Embodiment 3

[0064] A construction method of an anti-cracking type floor is carried out as follows:

[0065] A. First grind and clean the ground, and then lay a layer of concrete to form a concrete base;

[0066] B. Spray anti-crack primer on the concrete base and let it dry naturally;

[0067] C. Lay 2 layers of glass fiber cloth on the dried anti-crack primer;

[0068] D. Lay mortar on the glass fiber cloth, embed steel mesh in the uncured mortar, and use a vibrator to compact it;

[0069] E. The tamped mortar is scraped off with a scraper and cured naturally;

[0070] F. Finally, brush the wear-resistant topcoat on the surface of the mortar. After one layer, wait for natural drying and then paint another layer, and then dry it naturally and then paint another layer. Brush three times in total.

[0071] In the present embodiment, in terms of mass percentage, the anti-crack primer in step B consists of 40% castor oil short oil alkyd resin, 20% tertiary vinegar resin, 10% calcium zircon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com