A water collecting cup heater for diesel engine

A diesel engine and water collection cup technology, which is applied in the direction of engine starting, engine components, machines/engines, etc., can solve problems such as temperature delay, poor conduction effect, and jumping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

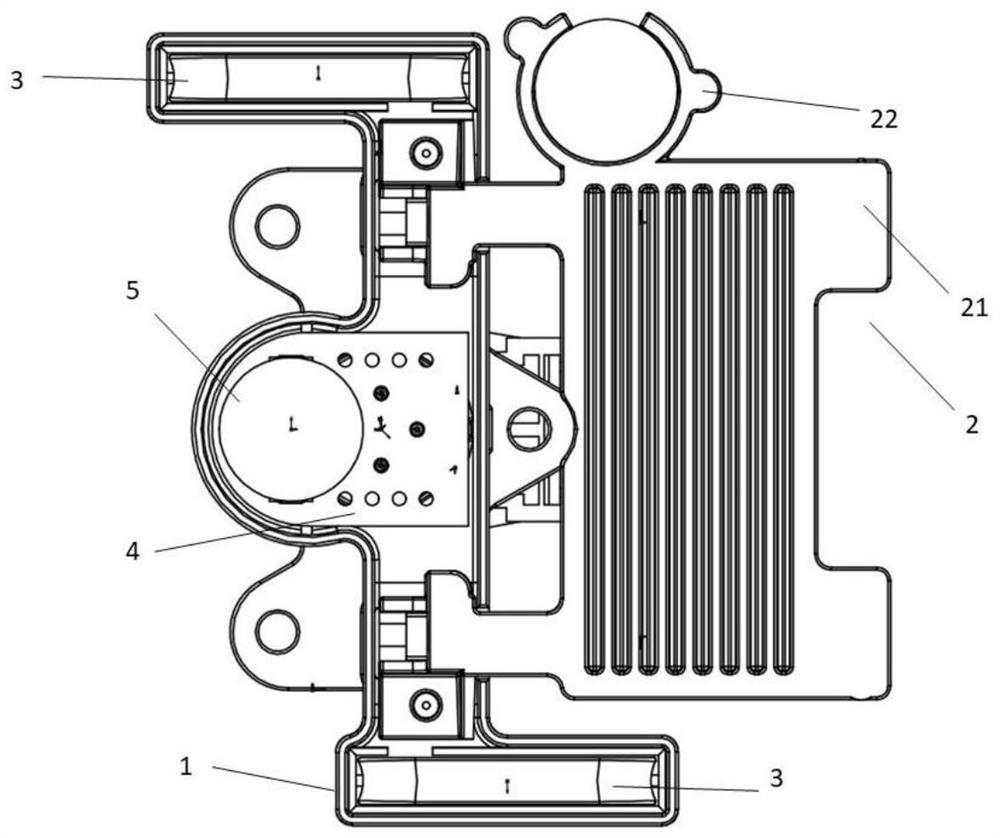

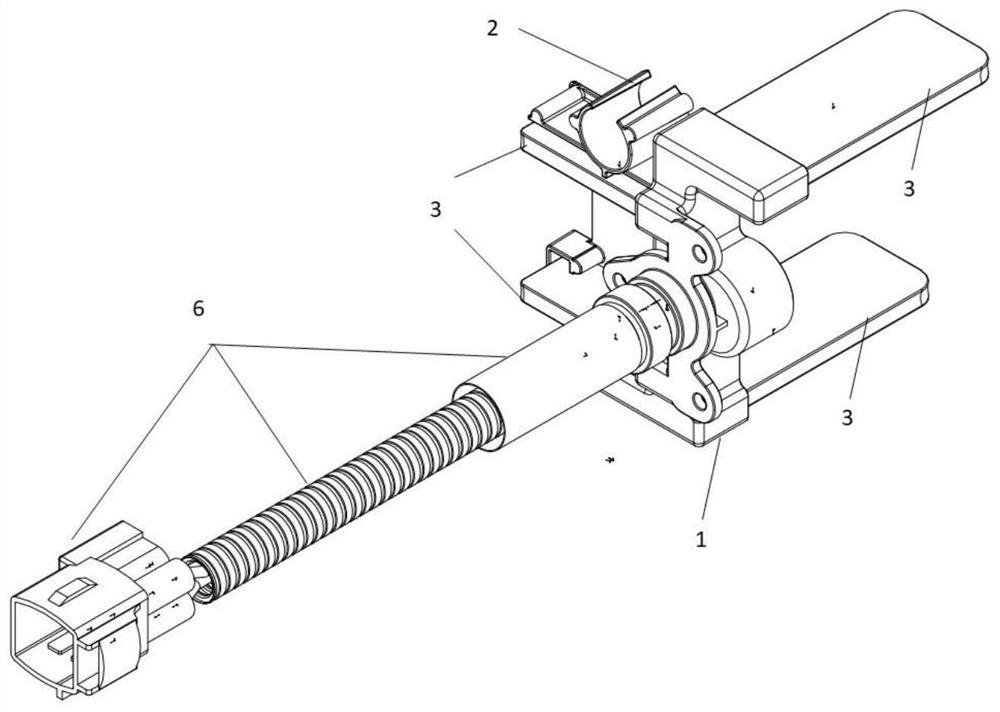

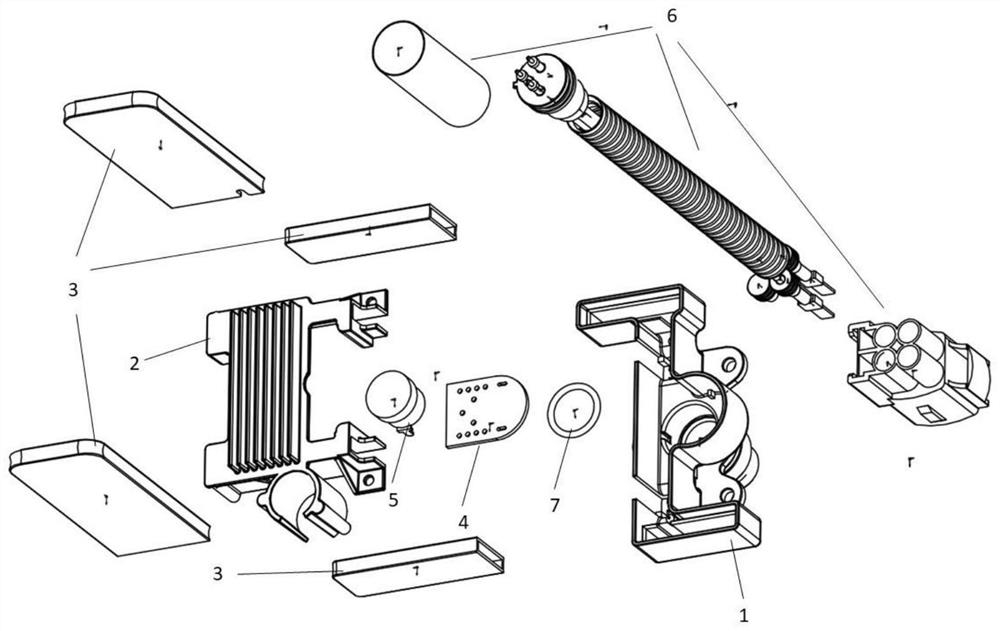

[0036] combine Figure 1-6 , a water collection cup heater for a diesel engine, including a housing 1, a heat sink 2, a heating plate 3, a PCB circuit board 4, a temperature controller 5 and a connection assembly 6, the housing 1 includes a bottom surface and is arranged on the edge of the bottom surface The raised wall; the heat sink 2, the heating plate 3, the PCB circuit board 4 and the temperature controller 5 are installed on the housing 1, and the connection assembly 6 is connected to the housing 1 and connected to the temperature controller 5 and the heating plate 3; the PCB The circuit board 4 is arranged parallel to the bottom surface of the housing 1; the heating sheet 3 is elongated, and the cooling sheet 2 includes a main body cooling part 21 connected to the heating sheet 3 and a C-shaped water discharge valve cooling ring part 22, the main body cooling part and the water discharge valve. The heat dissipation ring part of the valve is integrally formed, and the co...

Embodiment 2

[0040] A control method for a water collection cup heater for a diesel engine, using a connection assembly 6 to supply power to a PCB circuit board 4, a thermostat 5, and a heating sheet 3, and the thermostat 5 collects the temperature of a measurement point, and the temperature on the PCB circuit board 4 A controller is provided, and the controller monitors the detection temperature of the thermostat 5, and controls the heating power of the heating sheet 3 according to the temperature;

[0041] An ambient temperature sensor is also provided, which is a third temperature sensor, and the third temperature sensor detects the temperature of the surrounding environment;

[0042] It is characterized in that the control method comprises the following steps:

[0043] Startup steps:

[0044] After the controller receives the diesel engine start signal from the control bus, the controller controls all heating plates to start heating directly; the controller obtains the temperature T3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com