Detector Dewar assembly and focal plane detector

A technology of focal plane detectors and detector chips, which is applied in the field of infrared detectors, can solve problems such as the negative impact of noise ratio and noise, and achieve the effect of compact structure and improved shielding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

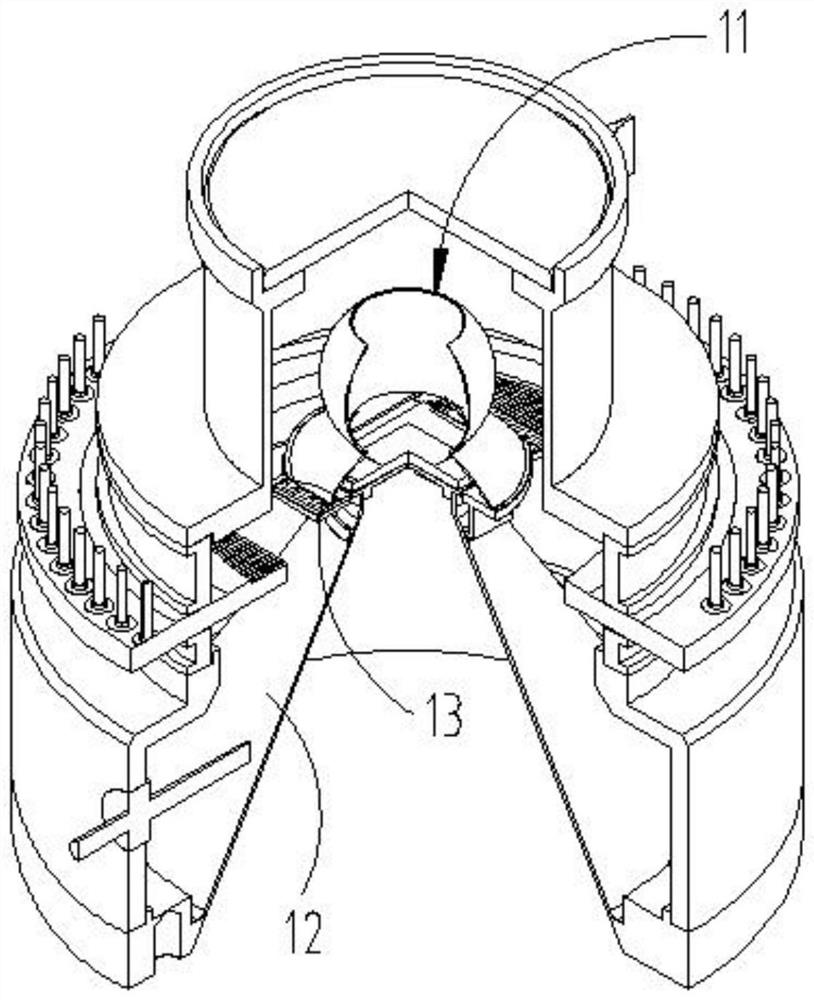

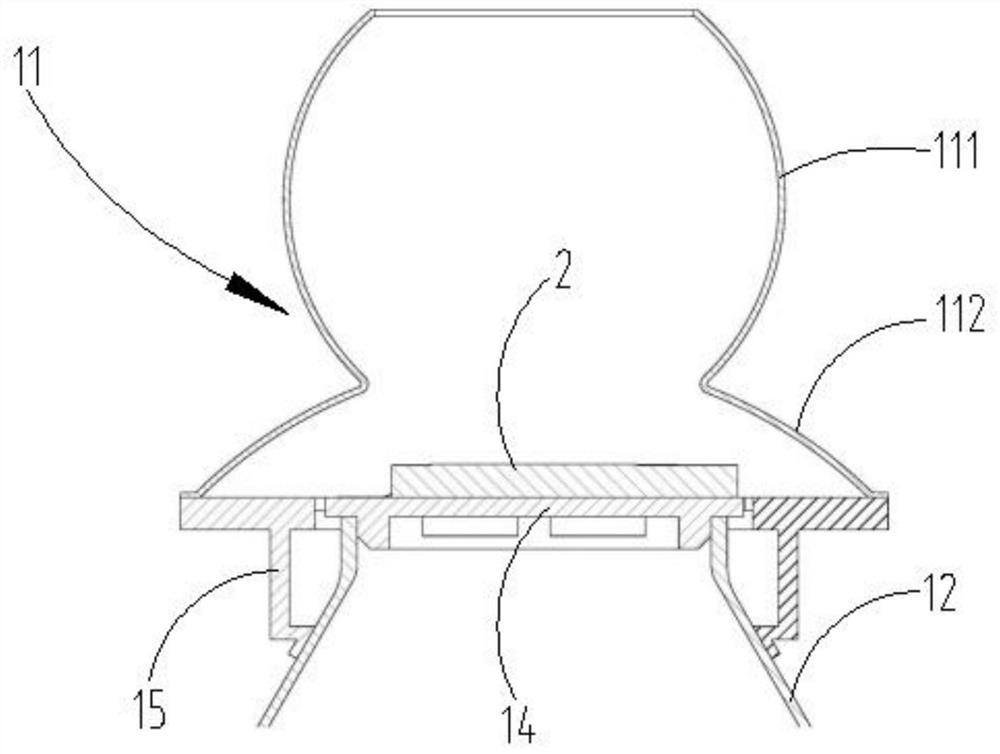

[0020] Such as figure 1 with figure 2 The embodiment of the present invention provides a Dewar assembly of a detector, including a cold plate 14, a cold finger cylinder 12, a cold shield 11 and a cold shield support 15, the cold shield support 15 is installed on the cold finger cylinder 12, the The cold screen 11 includes a mounting portion 112 and a shielding portion 111, the mounting portion 112 is mounted on the cold screen support 15 and encloses the cold plate 14 inside, and the shielding portion 111 is separated from the mounting portion 112. The free end is extended outward and has a spherical structure.

[0021] Generally, the above-mentioned cold plate 14 has a chip mounting position, which is used for packaging the detector chip 2. The cold plate 14 can efficiently conduct cold energy to the detector chip 2, so that the detector chip 2 can quickly cool down and work stably. The cold plate 14 is installed on the cold finger cylinder 12. Generally, a refrigerator is...

Embodiment 2

[0028] An embodiment of the present invention provides a focal plane detector, including the Dewar assembly of the detector provided in the first embodiment above, and the detector chip 2 is packaged on the cold plate 14 . Apparently, the focal plane detector also includes structures such as a refrigerator, which is a conventional design in the field, and will not be described in detail here.

[0029] In one of the embodiments, the above-mentioned detector chip 2 is directly mounted on the cold plate 14 by glue, which can further increase the cooling speed of the detector chip 2 .

[0030] Further, as figure 1 , the focal plane detector also includes a ceramic substrate 13, the ceramic substrate 13 is installed on the cold shield support 15 and is electrically connected with the detector chip 2, the electrical connection between the ceramic substrate 13 and the detector chip 2 The connection structure is a conventional technique in the art, and will not be described in detail...

Embodiment 3

[0032] An embodiment of the present invention provides a throttling refrigerator, which can be used as the refrigerator in the second embodiment above.

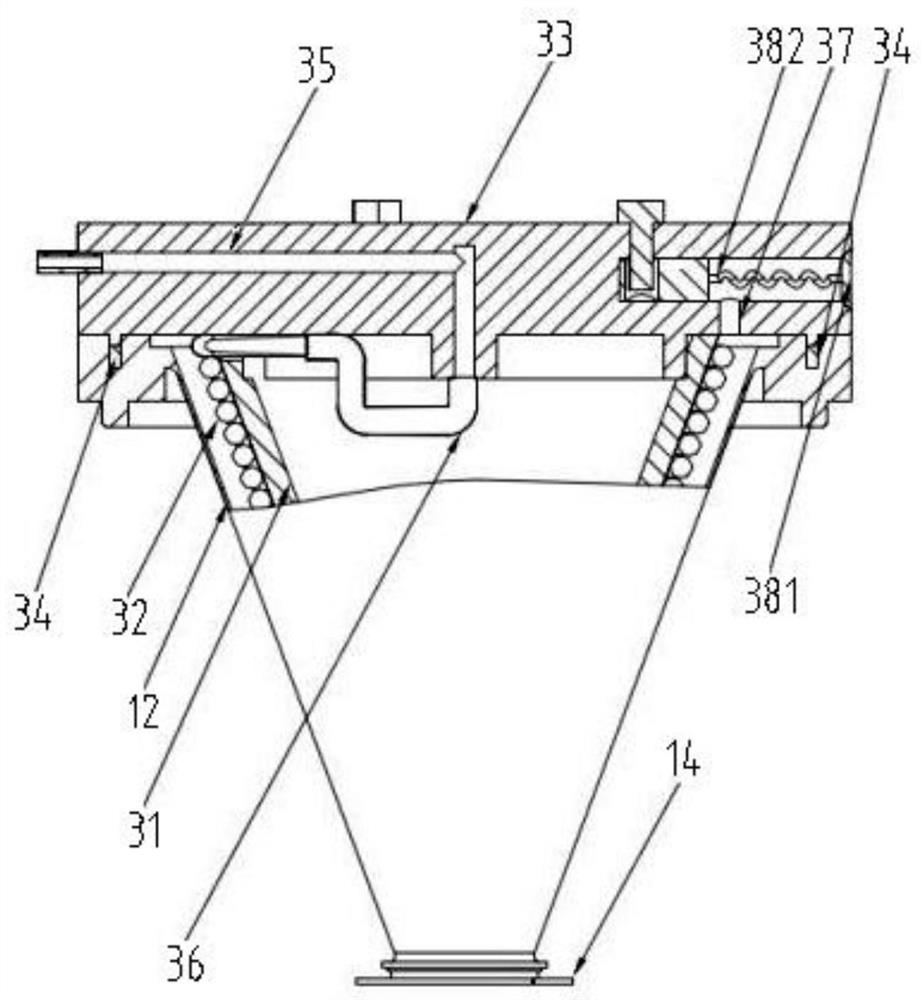

[0033] Such as image 3 , the throttling refrigerator includes a mandrel 31, a cold finger cylinder 12, a flange 33 and a heat exchange tube 32, the heat exchange tube 32 is provided with a throttling part, and the cold finger cylinder 12 is sleeved on the core An expansion chamber is formed outside the shaft 31 and between the mandrel 31, the heat exchange tube 32 is wound on the outer wall of the mandrel 31 and communicates with the expansion chamber through the throttling part. The flange 33 is connected to the cold finger cylinder 12 and closes the expansion chamber, and the flange 33 is provided with an intake passage communicated with the heat exchange tube 32 and an exhaust passage 37 communicated with the expansion chamber . Wherein, the mandrel 31 and the cold finger cylinder 12 are conventional components in the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com