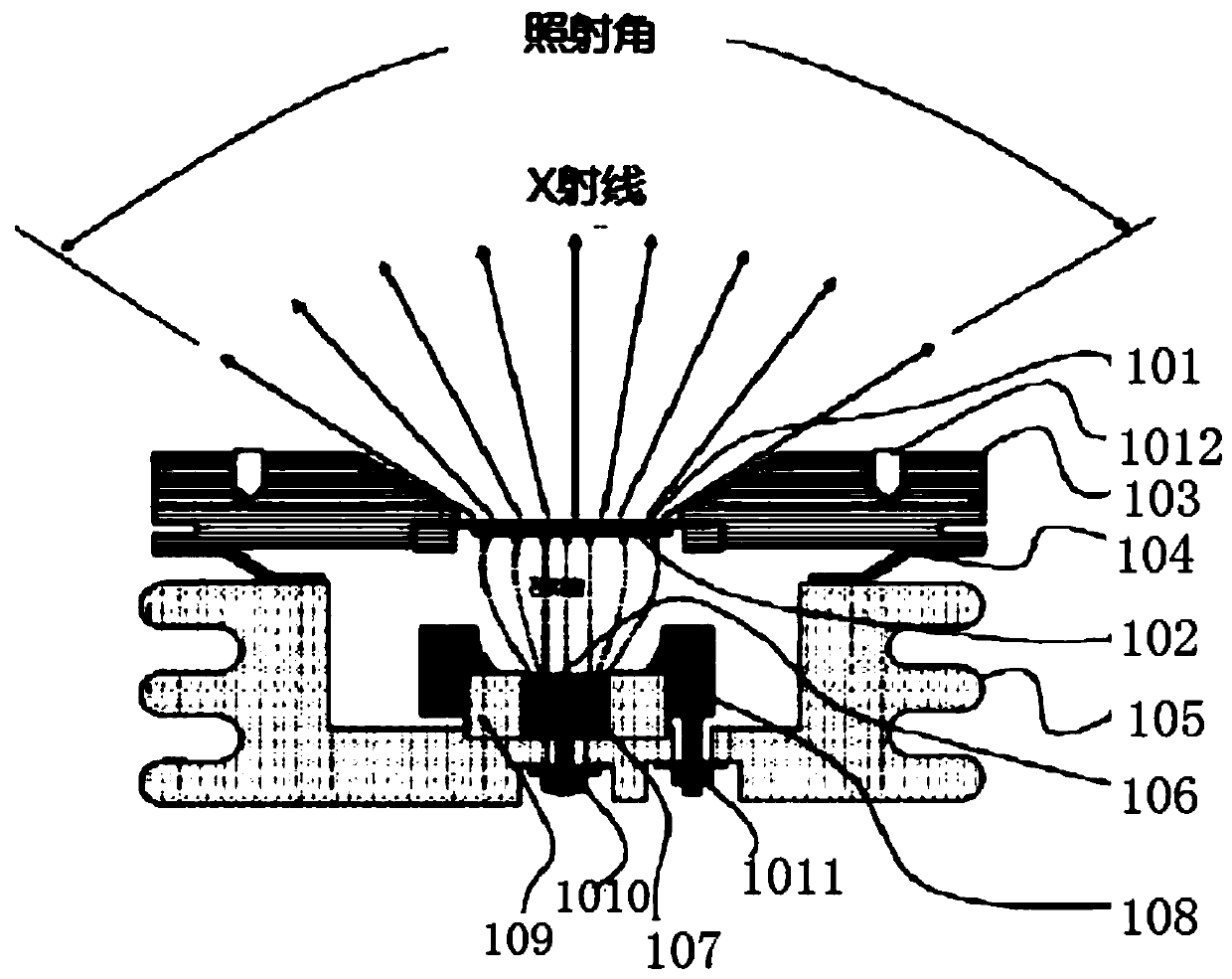

Field emission cold cathode soft X-ray tube using carbon nanotubes

A carbon nanotube and field emission technology, applied in the direction of X-ray tube, X-ray tube electrode, X-ray tube parts, etc. problems, to avoid the problem of shortening life, save power consumption, and reduce power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0070] Embodiment 1. The main parameters of the soft X-ray generating device made by the present invention are as follows:

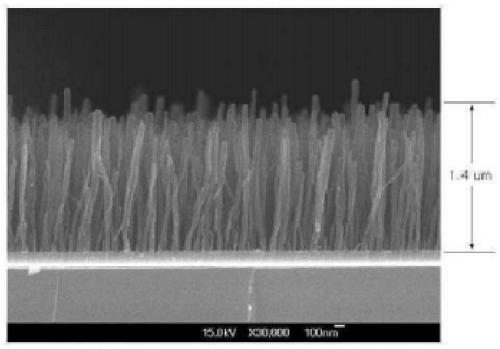

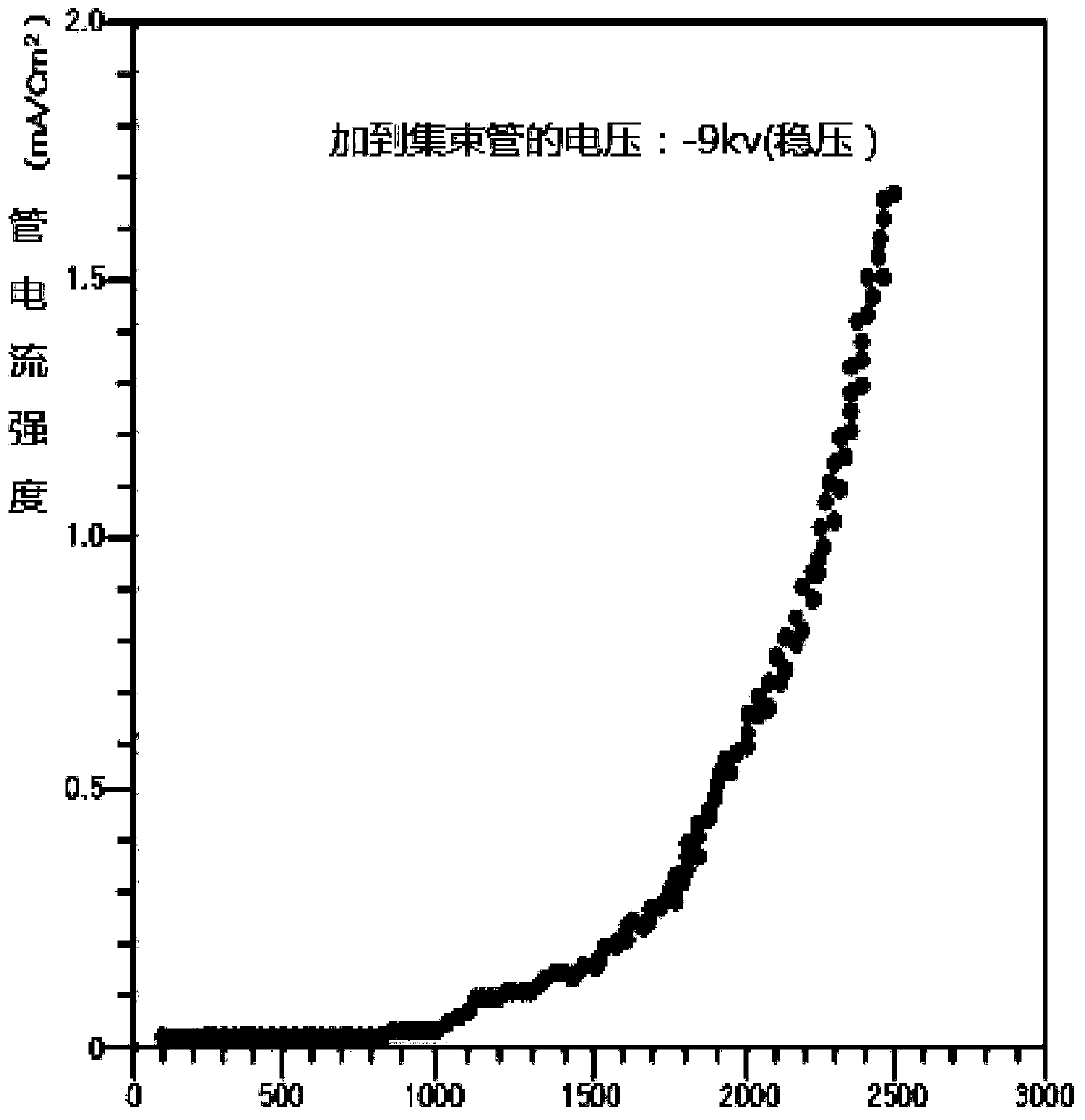

[0071] Overall size: 40φ×25H, beryllium window thickness: 120μm, beryllium window outer size: 20φ, beryllium window 101 and gold (Au) target 102 size: 15φ, gold (Au) target 102 thickness: 1μm, carbon nanotubes Nickel (Ni) reactor size of electron emission surface 106: 12φ×0.5t, input voltage of drive power Vc502 for electron emission: variable up to 2500V, input voltage of power supply VH501 for clustering and accelerating electrons: negative 9kV, carbon nano The distance between the tube electron emission surface 106 and the gold (Au) target 102: 10mm.

[0072] In order to produce soft X-rays that are conducive to eliminating static electricity, the power supply connected to the X-ray tube of the present invention such as Figure 5 As shown, the cathode portion of the metal base 107 with the carbon nanotube electron emission surface 106 is connected to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com