Sunscreen emulsion and preparation method thereof

A technology for sunscreen lotion and preservatives, applied in pharmaceutical formulations, cosmetic formulations, cosmetic formulations, etc., can solve problems such as skin allergies, chemical sunscreens are prone to oxidative deterioration, secondary skin damage, etc., to inhibit diffusion, reduce The effect of sunburn cell formation and prevention of free radical formation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

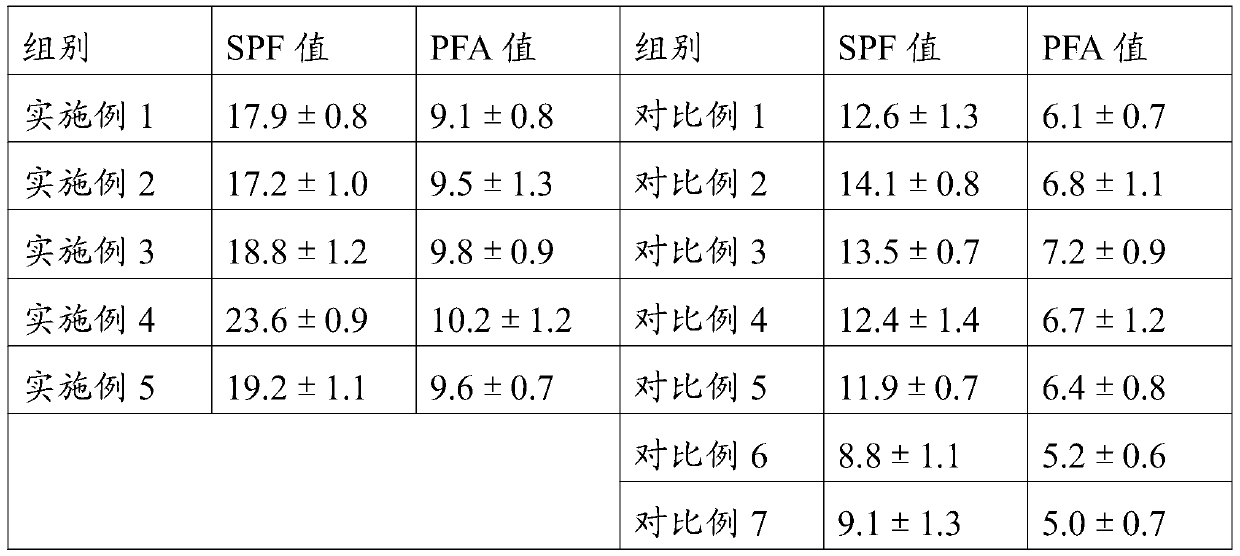

Examples

Embodiment 1

[0023] Accurately weigh 10 parts of soybean lecithin, 10 parts of caprylic triglyceride, 2 parts of glycerin, 805 parts of Tween, 0.05 part of tyrosine, 0.05 part of ribonucleoside, 0.2 part of Lycium barbarum polysaccharide, and the particle size is 50-200nm 2 parts of titanium dioxide, 1 part of nasturtium extract, 1 part of phenoxyethanol, 40 parts of deionized water for later use.

[0024] Stir and mix the above weighed soybean lecithin, caprylic triglyceride, Tween-80, titanium dioxide, nasturtium extract and phenoxyethanol at 45°C and keep it warm for 10 minutes to obtain an oil phase mixture; Glycerin, tyrosine, ribonucleoside, and wolfberry polysaccharide were dissolved in deionized water, and heated to 45°C for 10 minutes to obtain a water phase mixture; the above oil phase mixture was added to the water phase mixture for stirring and premixing, and then high-speed The primary emulsion was obtained by shearing for 20 minutes, and finally the sunscreen emulsion was obt...

Embodiment 2

[0026] Accurately weigh 15 parts of soybean lecithin, 8 parts of caprylic triglyceride, 5 parts of propylene glycol, 808 parts of Tween, 0.08 part of phenylalanine, 0.06 part of deoxyribonucleoside, 0.3 part of wolfberry polysaccharide, and the particle size is 50- 1 part of 200nm titanium dioxide, 2 parts of nasturtium extract, 1 part of p-hydroxyacetophenone, and 35 parts of deionized water for later use.

[0027] Stir and mix the above weighed soybean lecithin, caprylic triglyceride, Tween-80, titanium dioxide, nasturtium extract and p-hydroxyacetophenone at 50°C and keep it warm for 10 minutes to obtain an oil phase mixture; Dissolve the weighed glycerin, phenylalanine, deoxyribonucleoside, and wolfberry polysaccharide in deionized water, and heat to 50°C for 10 minutes to obtain the water phase mixture; add the above oil phase mixture to the water phase mixture for premixing , and then subjected to high-speed shearing for 30 minutes to obtain the primary emulsion, and fin...

Embodiment 3

[0029] Accurately weigh 20 parts of soybean lecithin, 6 parts of caprylic triglyceride, 4 parts of butanediol, 808 parts of Tween, 0.01 part of tryptophan, 0.05 part of ribonucleoside, 0.1 part of wolfberry polysaccharide, and the particle size is 50- 5 parts of 200nm titanium dioxide, 2 parts of nasturtium extract, 2 parts of phenoxyethanol, 40 parts of deionized water for later use.

[0030] Stir and mix the above weighed soybean lecithin, caprylic triglyceride, Tween-80, titanium dioxide, nasturtium extract and phenoxyethanol at 55°C and keep it warm for 10 minutes to obtain an oil phase mixture; The butanediol, tryptophan, ribonucleoside, and Lycium barbarum polysaccharide were dissolved in deionized water, and heated to 55°C for 10 minutes to obtain the water phase mixture; the above oil phase mixture was added to the water phase mixture for stirring and premixing, and then Perform high-speed shearing for 40 minutes to obtain primary emulsion, and finally homogenize for 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com