Modified biochar and preparation method, use method and recycling method thereof

A biochar and modification technology, applied in the field of biomass resource utilization, can solve problems such as the adsorption capacity cannot meet the requirements, and achieve the effects of short time consumption, alleviation of water eutrophication, and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

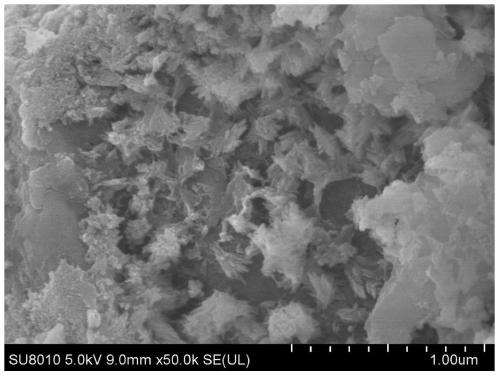

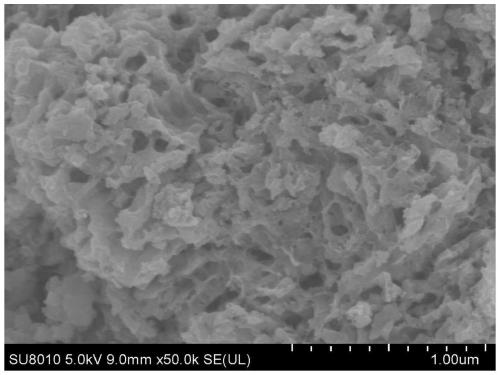

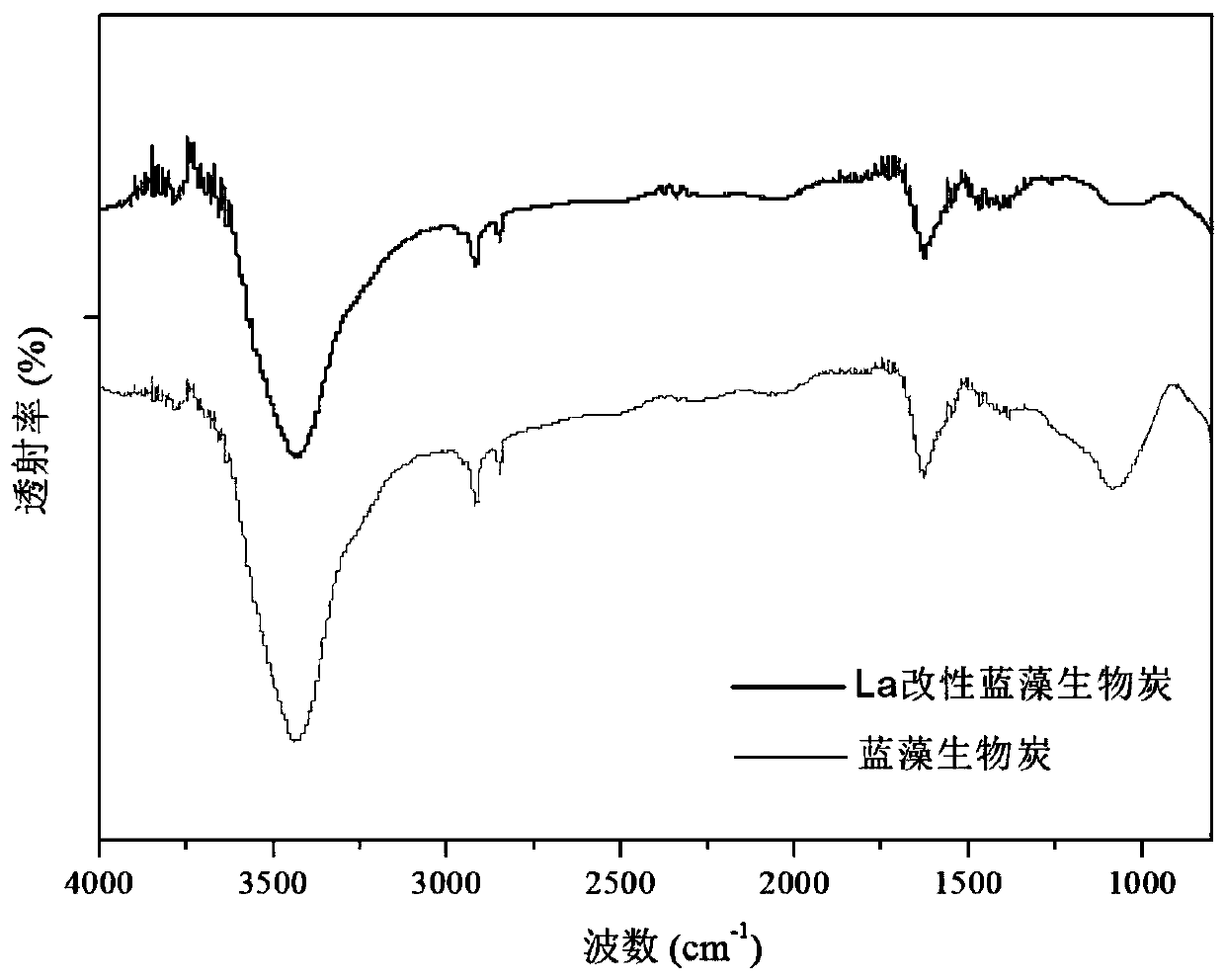

Image

Examples

Embodiment 1

[0026] In the modified biochar of this embodiment, the mass ratio of cyanobacteria to lanthanum chloride is 1:2.5, and the concentration of lanthanum chloride solution is 1mol / L.

[0027] The preparation method of the modified biochar of the present embodiment comprises the steps:

[0028] Step 1: After cleaning and drying the collected cyanobacteria, place them in 1mol / L lanthanum chloride solution and immerse them for 6 hours, the ratio of cyanobacteria to lanthanum chloride solution is 1g:10mL, filter and dry;

[0029] Step 2: Place the treated cyanobacteria in a tube furnace under the protection of nitrogen, the nitrogen flow rate is 2mL / min, the heating rate is 10°C / min, and pyrolyzes at 600°C for 2h to obtain modified lanthanum chloride Sexual cyanobacteria biochar;

[0030] Step 3: Prepare a 10mg / L potassium dihydrogen phosphate solution, take 0.1g of lanthanum chloride modified cyanobacteria biochar, put it into 50mL of phosphate solution, put it in a rotary mixer, ro...

Embodiment 2

[0033] In the modified biochar of this example, the mass ratio of cyanobacteria to lanthanum chloride is 1:5, and the concentration of lanthanum chloride solution is 2mol / L.

[0034] The preparation method of the modified biochar of the present embodiment comprises the steps:

[0035] Step 1: After cleaning and drying the collected cyanobacteria, place them in 2mol / L lanthanum chloride solution and soak for 12 hours, the ratio of cyanobacteria to lanthanum chloride solution is 1g:10mL, filter and dry;

[0036] Step 2: Place the treated cyanobacteria in a tube furnace under the protection of nitrogen, the nitrogen flow rate is 3mL / min, the heating rate is 8°C / min, and pyrolyzed at 700°C for 1.5h to obtain lanthanum chloride Modified cyanobacteria biochar;

[0037] Step 3: Prepare a 10mg / L phosphate solution, take 0.5g of lanthanum chloride modified cyanobacteria biochar, put it into 50mL of phosphate solution, put it in a rotary mixer, rotate at a speed of 60r / min for 24h, and...

Embodiment 3

[0040] In the modified biochar of this example, the mass ratio of cyanobacteria to lanthanum chloride is 1:3.5, and the concentration of lanthanum chloride solution is 1.5mol / L.

[0041] The preparation method of the modified biochar of the present embodiment comprises the steps:

[0042] Step 1: After cleaning and drying the collected cyanobacteria, place them in a 1.5mol / L lanthanum chloride solution and soak for 2 hours, the ratio of cyanobacteria to lanthanum chloride solution is 1g:10mL, filter and dry;

[0043] Step 2: Place the treated cyanobacteria in a tube furnace under the protection of nitrogen, the nitrogen flow rate is 4mL / min, the heating rate is 5°C / min, and pyrolyzed at 500°C for 1h to obtain modified lanthanum chloride Sexual cyanobacteria biochar;

[0044] Step 3: Prepare 10mg / L phosphate solution, take 1g of lanthanum chloride modified cyanobacteria biochar, put it into 50mL phosphate solution, put it in a rotary mixer, rotate at a speed of 60r / min for 24h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com