Central liquid supply planetary polishing device and method

A polishing device and liquid supply technology, which can be used in grinding drive devices, grinding/polishing equipment, optical surface grinders, etc. Process stability and adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

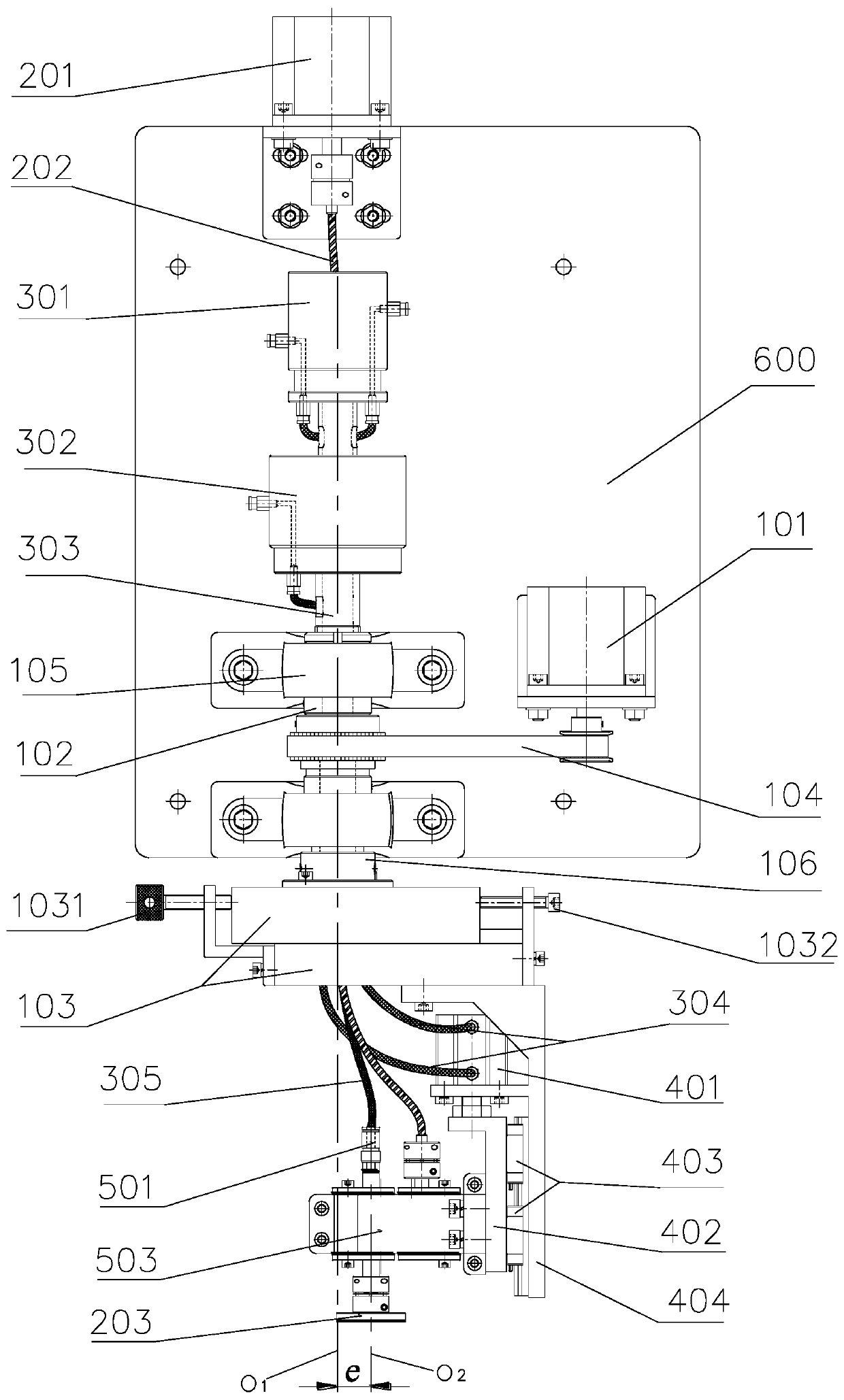

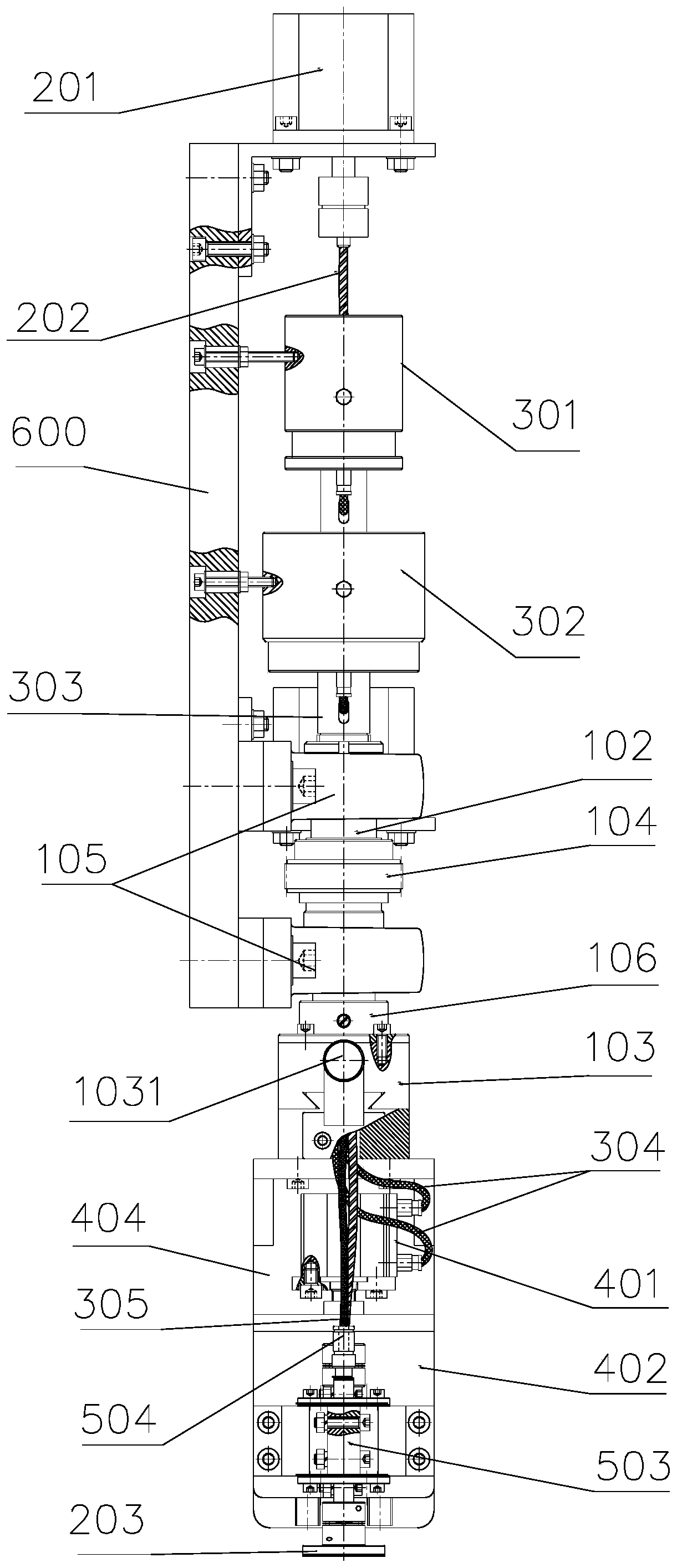

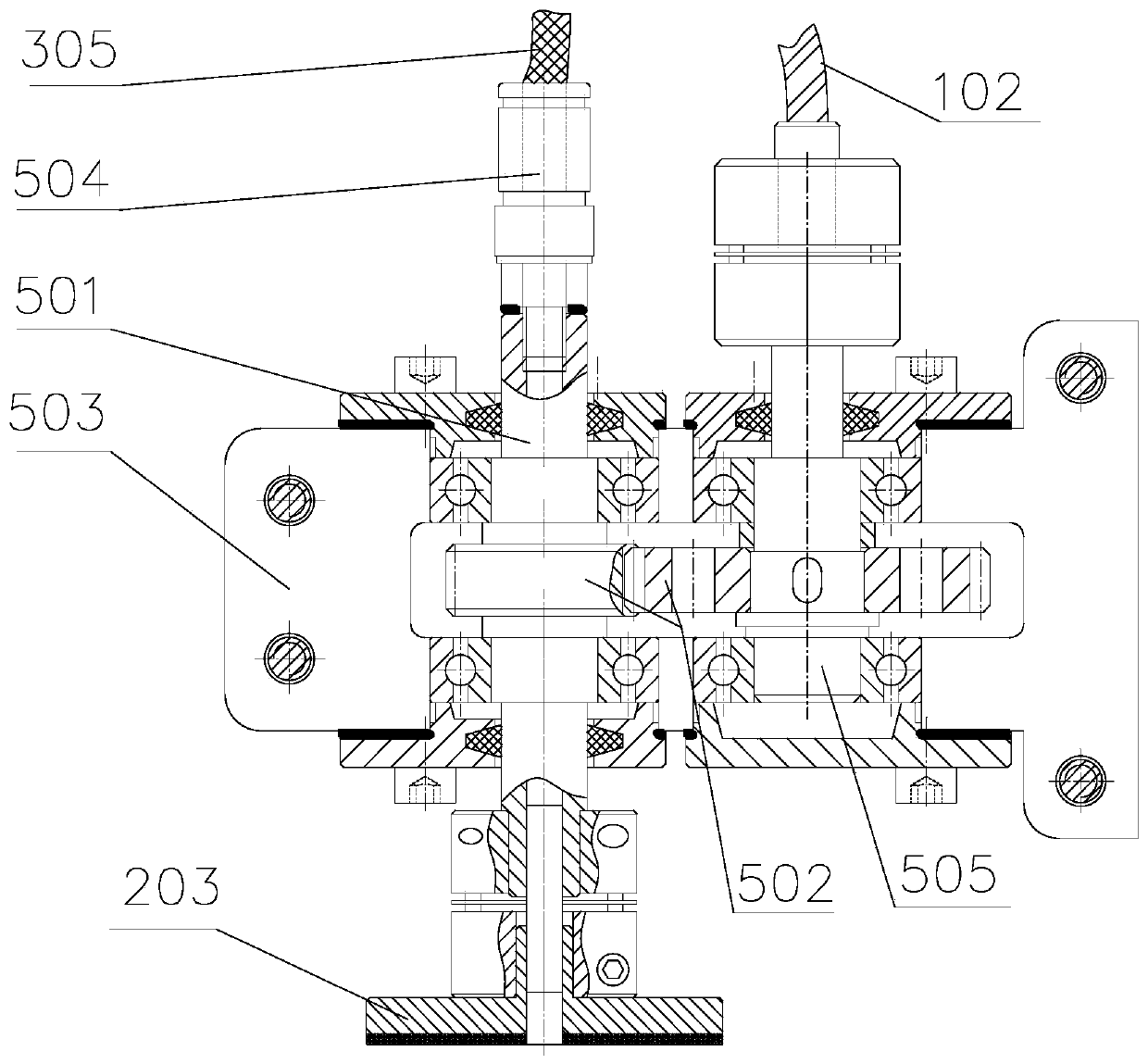

[0042] Such as figure 1 , figure 2 with image 3 As shown, in this example, the central liquid supply planetary polishing device of the present invention needs to be vertically installed on the moving shaft above the CNC machine table, the device is connected to the polishing liquid circulation system and the air pump with pipelines, and the workpiece is fixed on the on the machine table. Move the polishing disc 203 to a suitable position on the workpiece surface, use a pressure pump to pressurize the polishing solution to the working pressure, inject it from the water inlet hole of the hollow waterway rotary joint 302, and finally flow out from the center of the polishing disc 203 to the workpiece surface processing area. The air pump is used to inject compressed air at a set pressure from the air intake hole of the hollow air path rotary joint 301 and flow to the loaded thin-walled cylinder 401 to realize the loading of the polishing disc 203 on the surface of the workpie...

Embodiment 2

[0044] Such as figure 1 , figure 2 with image 3 As shown, in this example, the central liquid supply planetary polishing device of the present invention is installed at the end of the industrial robot, and the posture of the polishing disc relative to the surface of the workpiece is changed by controlling the posture of the industrial robot to adapt to the free-form surface element processing.

[0045] The device of the present invention can be installed not only on the moving shaft of ordinary numerical control machine tools, but also on the end of industrial robots, or even on a simple test bench built by oneself, which has strong versatility; by adjusting the size of the eccentricity e, an ideal The Gauss-like removal function makes the surface error converge quickly and improves the processing accuracy and efficiency; the polishing liquid is supplied from the center of the polishing disc through the hollow polishing shaft to prevent it from being thrown out due to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com