Method and system for directly recycling red mud alkali

A red mud alkali, direct technology, applied in chemical instruments and methods, alkali metal compounds, alkali metal carbonates, etc., can solve the problems of complex process and high processing cost, and achieve the effect of reducing processing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

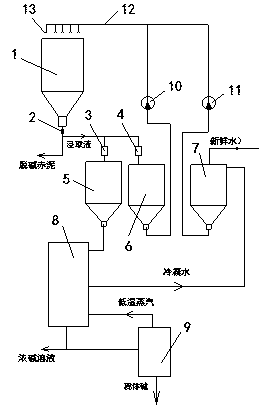

[0023] The invention directly recycles red mud alkali without adding any other components. Using circulating distilled water to leach about 4% (equivalent) caustic soda remaining in the red mud, the leaching solution is subjected to MVR+evaporation and crystallization to recover water, and cyclic leaching to obtain a high-concentration alkali solution or solid alkali.

[0024] The red mud alkali used in the present invention directly recycles and utilizes the system, as figure 1 As shown, the shower nozzles 13 are evenly arranged on the top of the leaching tank 1, and each nozzle 13 is connected with the infusion pipe 12, and the infusion pipe 12 passes through the leaching water pump 10 and the leaching water pump 11 and the alkaline circulating water storage tank 6 and the condensation water respectively. The water storage tank 7 is connected. A pH meter 2 is installed at the bottom drain of the leaching tank or vertical storage bin 1, and is connected to a high pH leachate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com