A kind of low dielectric constant ltcc material and preparation method thereof

A technology with low dielectric constant and main material, applied in the field of low dielectric constant LTCC materials and their preparation, can solve the problems of lower sintering temperature, low Q×f value, and no microwave dielectric properties of LMS-based ceramics. , to achieve the effect of promoting ceramic sintering, low dielectric constant and good process stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] The present invention also provides a kind of preparation method of low dielectric constant LTCC material, comprises the following steps:

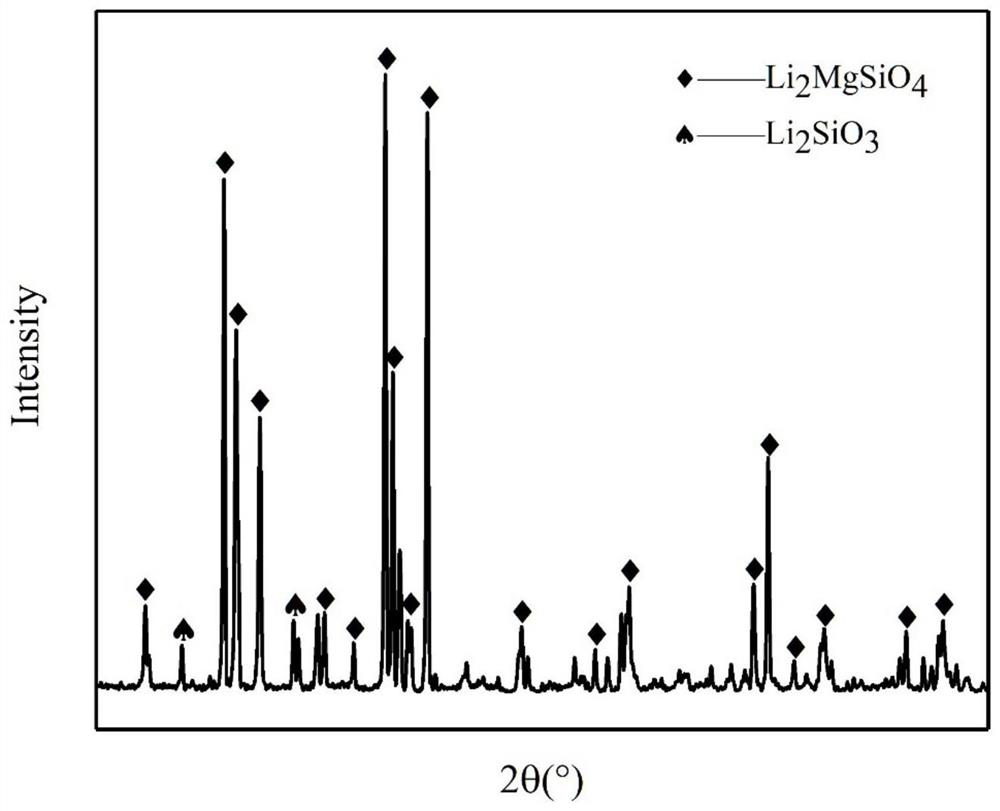

[0032] Step 1: Preparation of ceramic main material, Li 2 O-MgO-SiO 2 Ceramic materials with Li 2 CO 3 , MgO, SiO 2 As raw material, mole ratio Li 2 CO 3 :MgO:SiO 2 = 1:1:1 synthesized main crystal phase is Li 2 MgSiO 4 The main ceramic material; mix the mixed ingredients with deionized water, wet ball mill for 2 to 5 hours, dry and then sieve, grind evenly, pre-fire at 850-930°C for 4 hours to synthesize the main crystal phase as Li 2 MgSiO 4 Phase Li 2 O-MgO-SiO 2 Ceramic base material;

[0033] Step 2: Preparation of glass additive, La 2 o 3 , B 2 o 3 , ZnO by mass percentage: 45%≤La 2 o 3 ≤47%, 28%≤B 2 o 3 ≤32%, 21%≤ZnO≤25% ingredients, mix the prepared materials with deionized water, wet ball mill for 2-5 hours, dry and then sieve, pre-burn at 600-800°C for 4 hours, and then Melt the glass slag at a tempera...

Embodiment 1

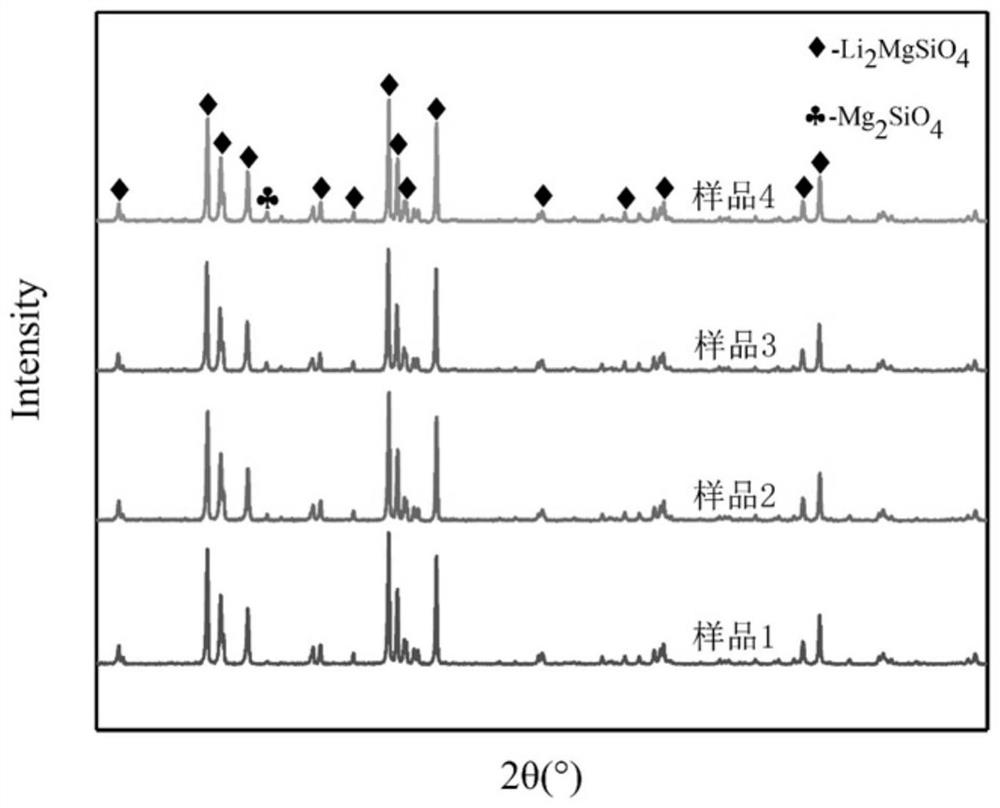

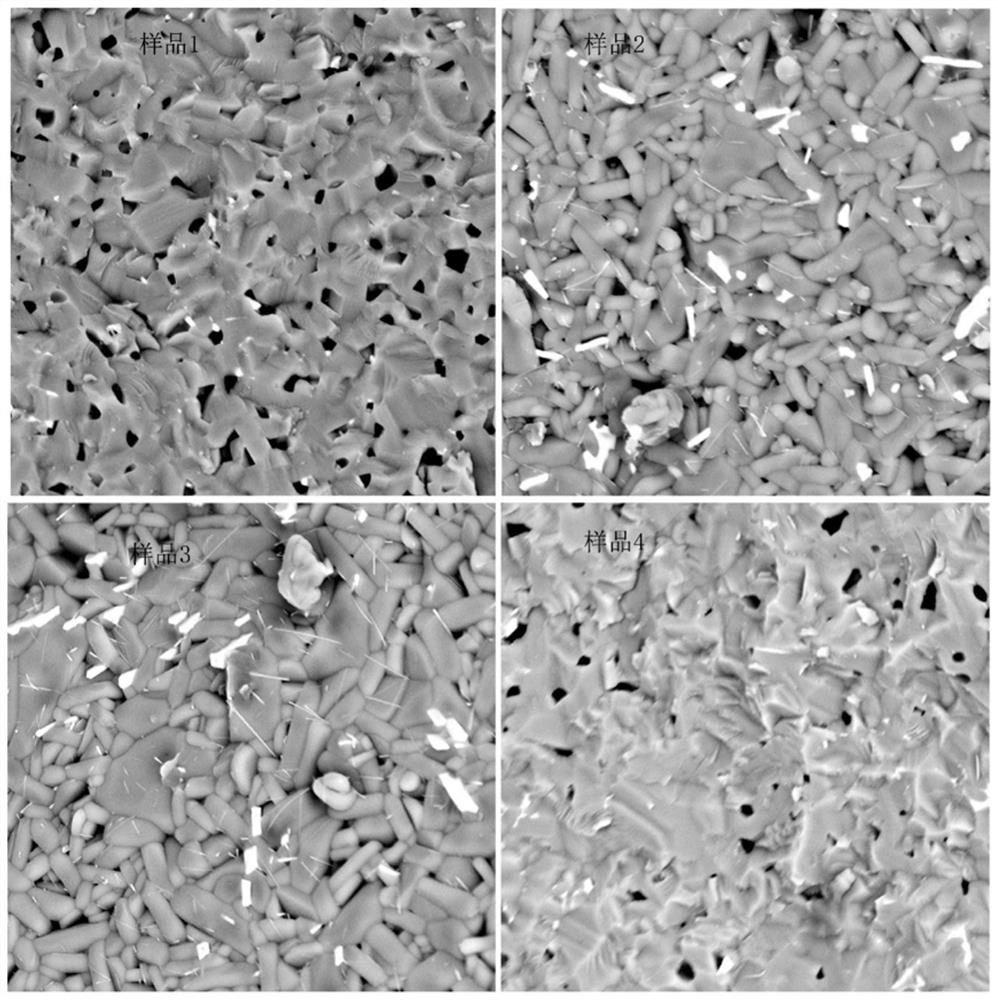

[0041] A kind of low dielectric constant LTCC material, be 100% Li by mass percentage 2 MgSiO 4 Composition, Li 2 MgSiO 4 The molar ratio of each component in Li is 2 O:MgO:SiO 2 =1:1:1, the sintering condition is 1250°C / 2h.

[0042] The above-mentioned low dielectric constant LTCC material is obtained by the following preparation method:

[0043] Preparation of Li 2 MgSiO 4 , Li 2 O-MgO-SiO 2 Ceramic materials with Li 2 CO 3 , MgO, SiO 2 As raw material, mole ratio Li 2 CO 3 :MgO:SiO 2 = 1:1:1 synthesized main crystal phase is Li 2 MgSiO 4 The ceramic main material (chemical equation is Li 2 CO 3 +MgO+SiO 2 = Li 2 MgSiO 4 ); Mix the mixed ingredients with deionized water, wet ball mill for 2 to 5 hours, dry and then sieve, grind evenly, pre-fire at 850-930°C for 4 hours to synthesize the main crystal phase as Li 2 MgSiO 4 Phase Li 2 O-MgO-SiO 2 Ceramic base.

Embodiment 2

[0045] A low dielectric constant LTCC material, according to mass percentage, its composition includes: 0.5% lanthanum boron zinc glass, 99.5% Li 2 MgSiO 4 ceramic powder;

[0046] The specific components of the lanthanum boron zinc glass are: 45.00% La 2 o 3 , 30.00% B 2 o 3 , 25.00% ZnO; the Li 2 MgSiO 4 The molar ratio of each component in the ceramic powder Li 2 O:MgO:SiO 2 =1:1:1.

[0047] The preparation method of embodiment 2 comprises the following steps:

[0048] Step 1: According to the composition ratio requirements of the lanthanum-boron-zinc glass (45.00% La 2 o 3 , 30.00% B 2 o 3 , 25.00% ZnO), the La 2 o 3 , B 2 o 3 , ZnO powder for uniform mixing ((chemical equation is Li 2 CO 3 +MgO+SiO2 = Li 2 MgSiO 4 )); mill the uniformly mixed powder for 4 hours, then dry and sieve, pre-fire at 700°C for 4 hours, melt at 1200°C for 1 hour, and cool with the furnace to obtain glass slag, which is crushed to obtain Lanthanum boron zinc glass powder;

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com