ABS plastic with high impact resistance

A modified and nanocellulose technology, applied in the field of plastics, can solve the problems of low impact resistance and poor heat dissipation of home appliance shells

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

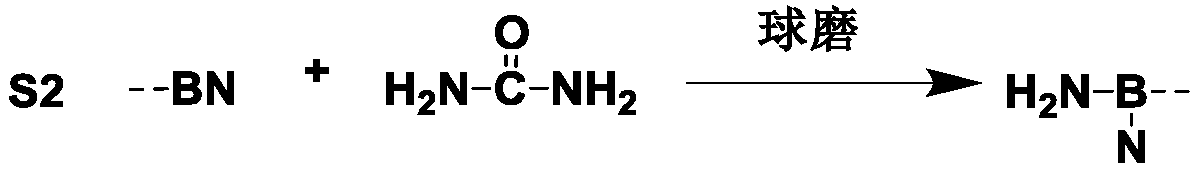

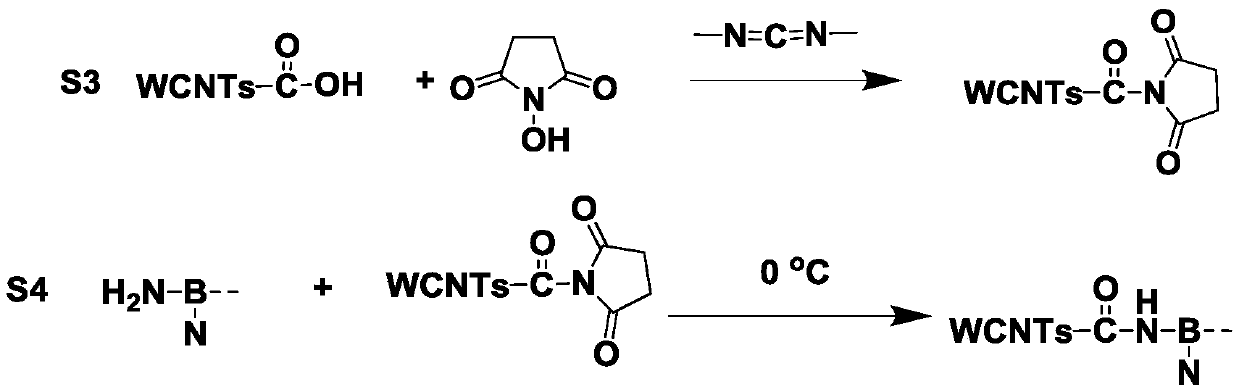

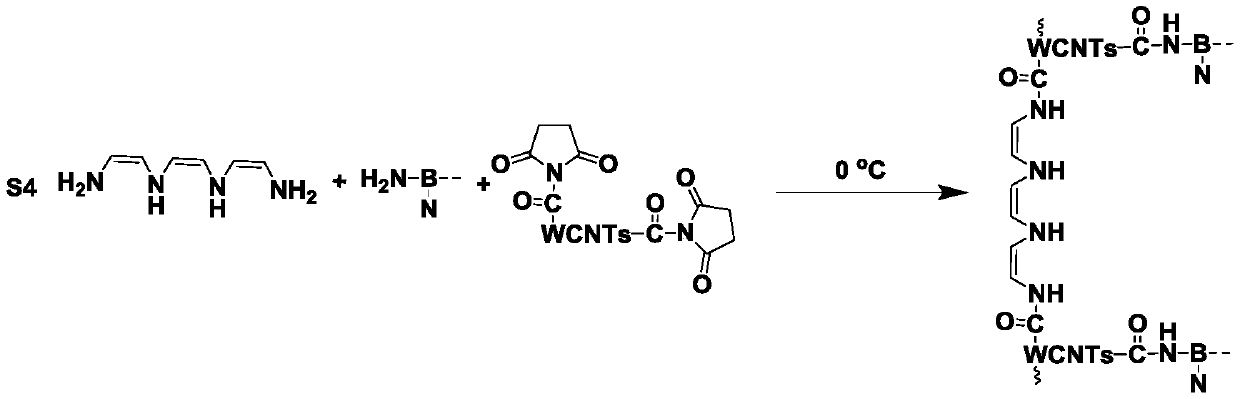

Method used

Image

Examples

Embodiment 1

[0085] A high-impact ABS plastic comprises the following components in parts by weight: 100 parts of ABS resin, 1 part of thermally conductive filler, 4 parts of antioxidant, 8 parts of silane coupling agent, 10 parts of flame retardant, and 0.8 part of anti-ultraviolet agent.

[0086] ABS plastic preparation method, comprises the following steps:

[0087] Dry the ABS resin in an oven; preheat the screw barrel of the injection molding machine and the injection mold; feed the dried ABS resin into the screw barrel of the injection molding machine and heat it to a molten state; add thermally conductive fillers, antioxidants, lubricants, Add silane coupling agent, flame retardant, and anti-ultraviolet agent to the molten ABS resin, mix well and spray it into the mold, and wait for the mold to cool to room temperature after completion; open the mold to take out the product in the mold, air-dry and cut into pellets Obtain the ABS plastic of the present invention.

[0088] The dryin...

Embodiment 2

[0102] A high-impact ABS plastic includes the following components by weight: 100 parts of ABS resin, 0.5 parts of thermally conductive filler, 4 parts of antioxidant, 8 parts of silane coupling agent, 10 parts of flame retardant, 0.8 part of anti-ultraviolet agent, initiator 2 doses.

[0103] ABS plastic preparation method, comprises the following steps:

[0104] Dry the ABS resin in an oven; preheat the screw barrel of the injection molding machine and the injection mold; feed the dried ABS resin into the screw barrel of the injection molding machine and heat it to a molten state; mix thermally conductive fillers, initiators, antioxidants, Lubricants, silane coupling agents, flame retardants, and anti-ultraviolet agents are added to the molten ABS resin, mixed well and then sprayed into the mold. After the mold is cooled to room temperature, the mold is opened and the product in the mold is taken out. The ABS plastic of the present invention is obtained by air-drying and pe...

Embodiment 3

[0119] Basically consistent with embodiment 2, its difference is only in:

[0120] A high impact-resistant ABS plastic includes the following components in parts by weight: 100 parts of ABS resin, 1 part of thermally conductive filler, 4 parts of antioxidant, 8 parts of silane coupling agent, 10 parts of flame retardant, 0.8 part of anti-ultraviolet agent, initiator 2 doses.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com