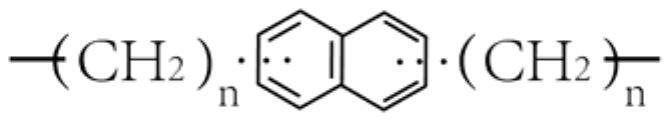

A kind of compressor oil for new energy vehicle-mounted sliding vane air compressor and preparation method thereof

An air compressor and compressor oil technology, which is applied in the petroleum industry, lubricating compositions, base materials, etc., can solve the problems of increased maintenance costs, oil product failure, etc., and achieve long oil change intervals, stable performance, and maintenance. cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

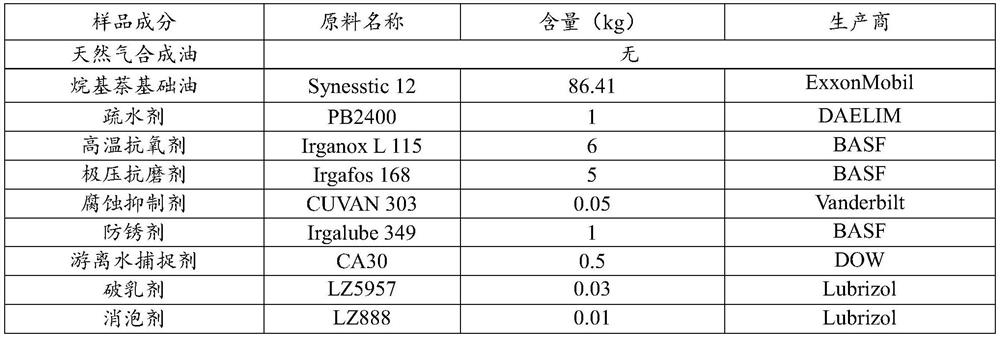

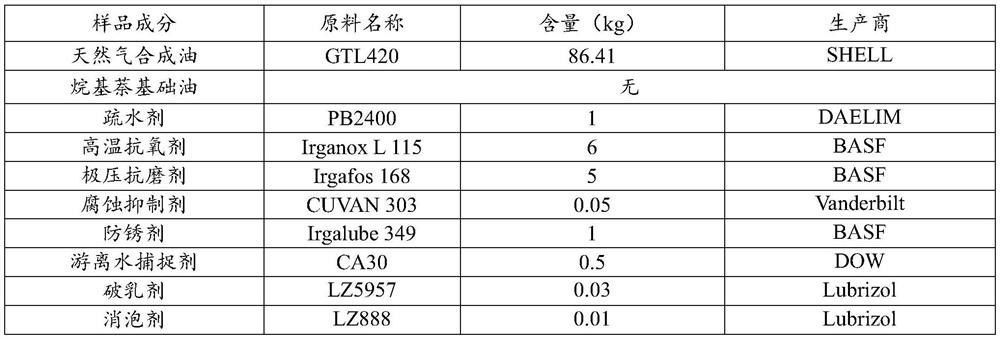

Embodiment 1

[0038] Example 1: A preparation method of compressor oil for a new energy vehicle-mounted vane air compressor:

[0039]Firstly add natural gas synthetic oil and alkyl naphthalene base oil with a total amount of 45-55wt% of the formula into the blending kettle, start stirring, the stirring temperature is 50°C±2°C, and the stirring speed is 100±10r / min. Maintain the temperature and stirring speed, add hydrophobic agent, high temperature antioxidant, extreme pressure antiwear agent, corrosion inhibitor, rust inhibitor, free water catcher and the remaining natural gas synthetic oil and alkyl naphthalene base oil in sequence, continue Maintain a stirring temperature of 50°C±2°C, a stirring speed of 100±10r / min, and stir for 1 to 2 hours. Then add demulsifier and defoamer in turn. Turn off the heat and cool to room temperature with stirring. The stirring time of the whole blending process is not less than 3 hours. That is, the compressor oil for the new energy vehicle-mounted van...

Embodiment 2

[0044] Sample composition raw material name Content (kg) manufacturer NGL GTL430 81.42 SHELL Alkylated naphthalene base oil Synesstic 5 10 ExxonMobil Hydrophobic agent PB2400 5 DAELIM High temperature antioxidant Irganox L 57 2 BASF Extreme Pressure Antiwear Agent Irgalube TPPT 1 BASF corrosion inhibitor CUVAN 303 0.3 Vanderbilt Rust inhibitor Sarkosyl O 0.03 BASF free water catcher CA30 0.1 DOW demulsifier LZ5957 0.1 Lubrizol Defoamer LZ888 0.05 Lubrizol

Embodiment 3

[0046] Sample composition raw material name Content (kg) manufacturer NGL GTL430 50 SHELL Alkylated naphthalene base oil Synesstic 12 40 ExxonMobil Hydrophobic agent PB2400 3 DAELIM High temperature antioxidant Irganox L 06 4 BASF Extreme pressure antiwear agent 1 Irgafos 168 1 BASF Extreme pressure antiwear agent 2 Irgalube TPPT 1 BASF corrosion inhibitor CUVAN 303 0.2 Vanderbilt Rust inhibitor Sarkosyl O 0.5 BASF free water catcher CA30 0.2 DOW demulsifier LZ5957 0.07 Lubrizol Defoamer LZ888 0.03 Lubrizol

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com