Super-lubricating water lubricating additive and preparation method thereof, super-lubricating water lubricating agent and application thereof

A lubricating additive and water lubrication technology, applied in the directions of additives, lubricating compositions, chemical instruments and methods, etc., can solve the problems of easy rupture of water film, limited application, poor lubrication performance of pure water, etc., and achieve stable process, reliable quality, Easy-to-operate effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

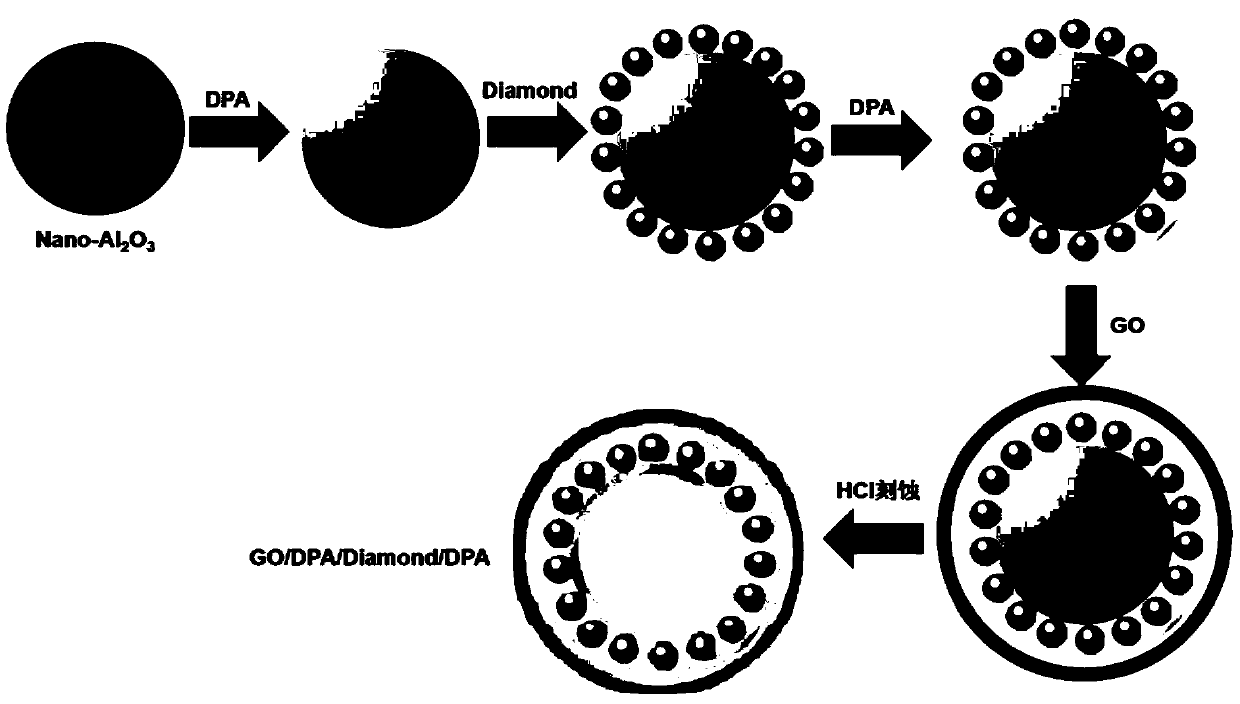

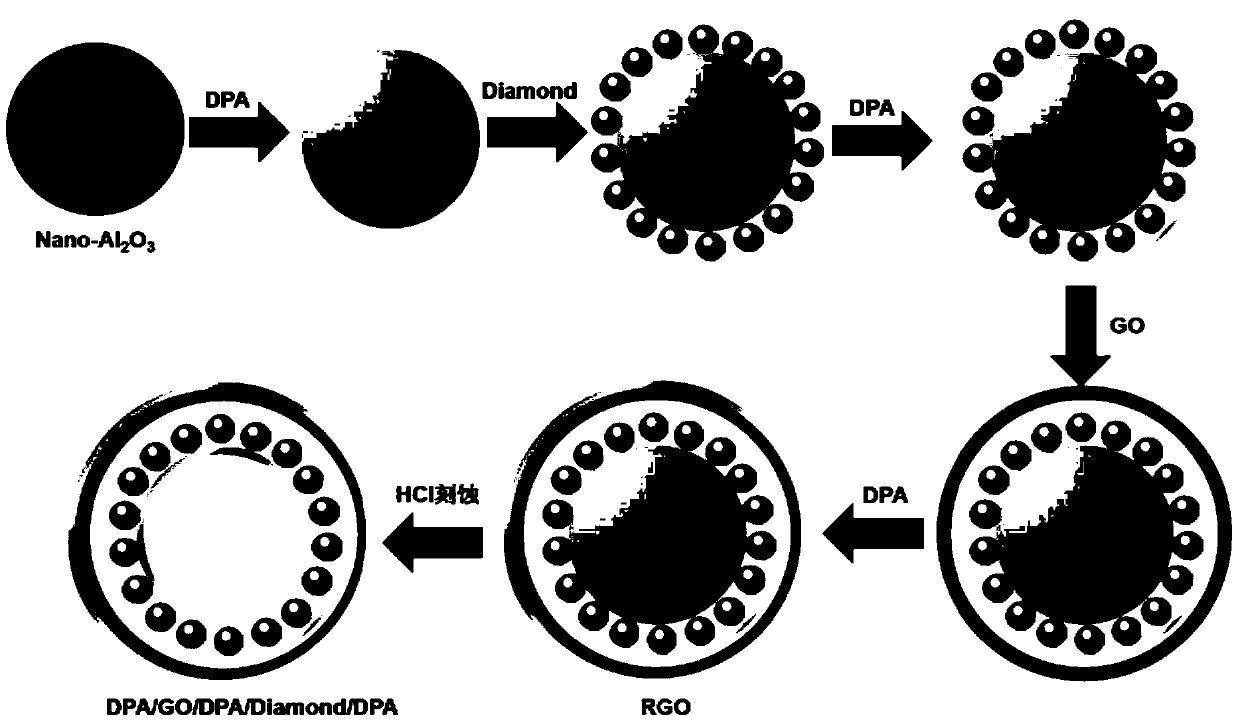

Image

Examples

Embodiment 1

[0045] (1) Prepare graphene oxide solution using Hummer's improved method: first, cool a 1000ml dry flask in an ice-water bath for 5min, then add 100ml of concentrated sulfuric acid, add 2g of flake graphite, 1.2g of sodium nitrate, and 8.0g of high manganese during stirring Potassium acid), the reaction temperature was controlled at 5°C in an ice-water bath, and the reaction was carried out with magnetic stirring for 2 hours. Then, the flask was taken out, placed on a constant temperature heating magnetic stirrer, and reacted with magnetic stirring at 35° C. for 2 h. Finally, 150ml of deionized water was added, and then the reaction temperature was raised to 95° C. with a constant temperature heating stirrer, and magnetic stirring was continued for 1 hour to obtain a graphite oxide solution with a concentration of 50 mg / ml. Add deionized water to dilute the graphite oxide solution, and ultrasonically shake for 2 hours to obtain a graphene oxide aqueous solution, put it in the...

Embodiment 2

[0051] This embodiment is the same as Embodiment 1, except that the concentration of the graphene oxide solution in step (3) is 0.5 mg / ml.

Embodiment 3

[0053] This embodiment is the same as Embodiment 1, except that the concentration of the graphene oxide solution in step (3) is 1.0 mg / ml.

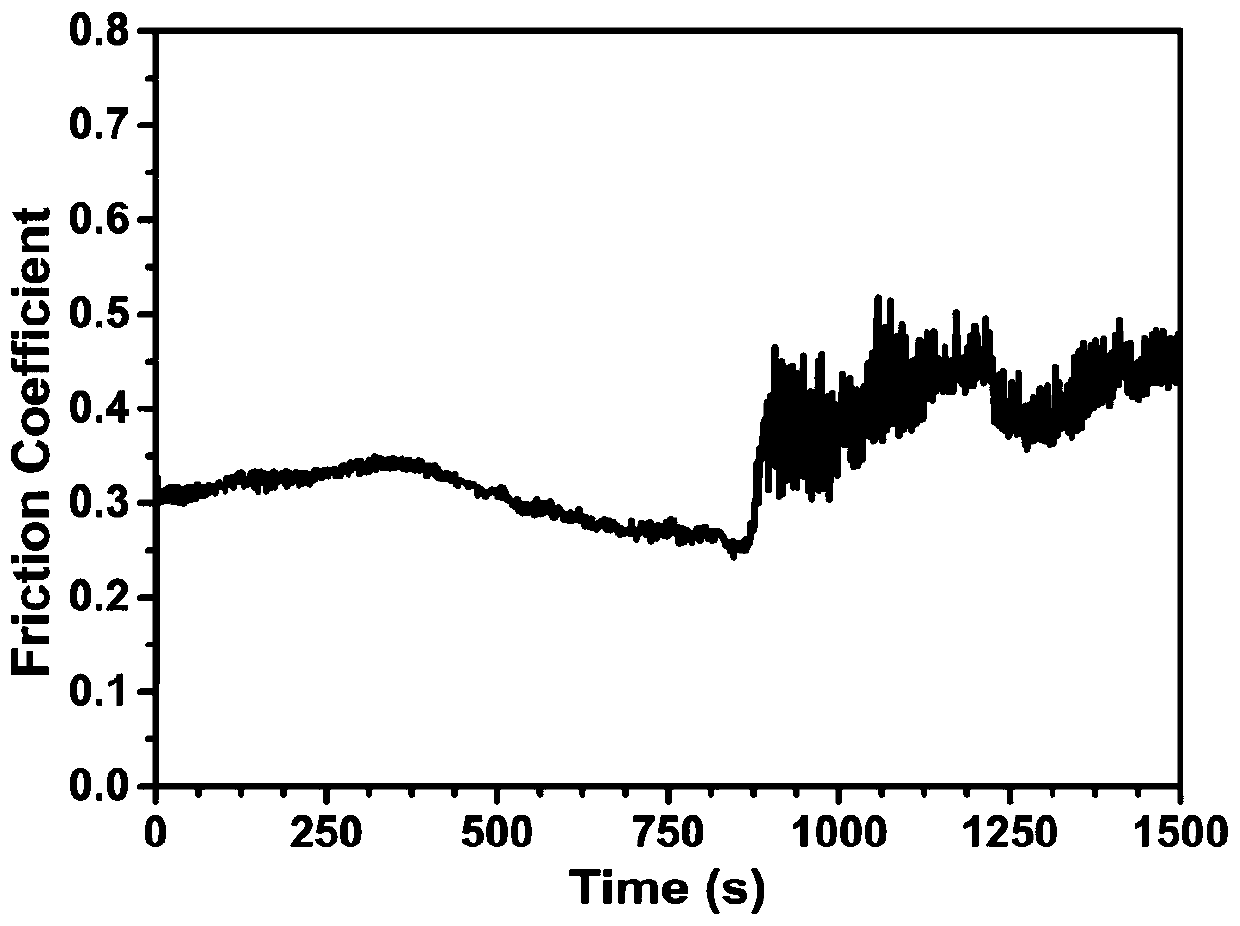

PUM

| Property | Measurement | Unit |

|---|---|---|

| friction coefficient | aaaaa | aaaaa |

| friction coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com