A heat treatment preparation method for heat-strength and corrosion-resistant steel

A technology of corrosion-resistant steel and steel billet, which is applied in the field of heat treatment preparation of heat-resistant corrosion-resistant steel, can solve the problems of poor resistance to plastic deformation and damage, uneven distribution of carbides, and reduced fatigue life of steel, so as to improve strength and Corrosion resistance, good chloride stress corrosion resistance, and extended service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

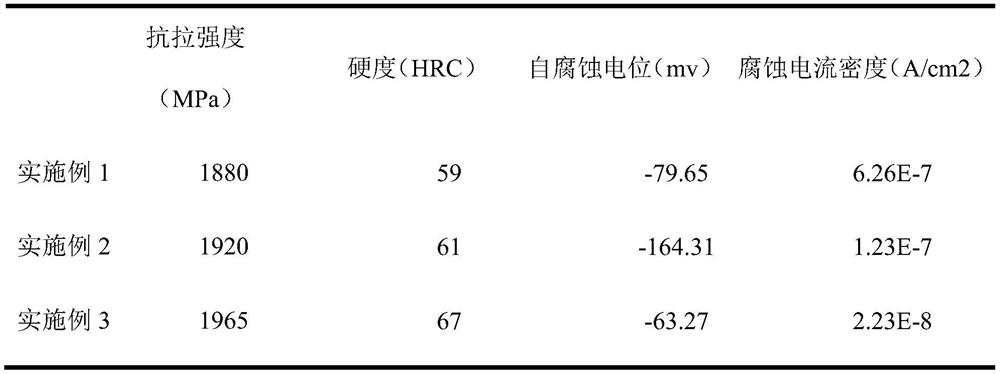

Embodiment 1

[0027] (1) Weigh each raw material component, mix the material, smelt it, and cast it into a billet; use a high-efficiency walking beam heating furnace for hot rolling; preheating section ≤ 850°C, heating section 1300°C, soaking section 1350°C , heat preservation 85min; start rolling temperature 1200°C, total billet heating time 240min; use the following components by weight as raw materials: C: 0.3%, Cr: 9%, Al: 4%, N: 1%, Nb : 0.04%, V: 0.12%, Mo: 0.18%, Mn: 4.2%, Si: 0.02%, S: 0.001-0.005%, Ba: 0.004%, Cu: 0.06%, the balance is Fe and unavoidable impurities .

[0028] (2) The number of times of rough rolling is 3 times, and the reduction ratio of each pass is controlled below 35%; after rough rolling, high pressure water is turned on to remove phosphorus, and the phosphorus removal pressure is 17MPa;

[0029] (3) Finish rolling: use KOCKS three-roller reducing sizing unit for rolling, set the temperature into KOCKS to be 820°C, the temperature of finish rolling to be 850°C...

Embodiment 2

[0033] (1) Weigh the components of each raw material, mix the materials, smelt them, and cast them into billets; use a high-efficiency walking beam heating furnace for hot rolling; the preheating section is ≤850°C, the heating section is 1250°C, and the soaking section is 1350°C , heat preservation 80min; start rolling temperature 1050°C, total billet heating time 150min; use the following components in parts by weight as raw materials: C: 0.35%, Cr: 8.5%, Al: 2.5%, N: 1%, Nb : 0.05%, V: 0.15%, Mo: 0.15%, Mn: 4%, Si: 0.05%, S: 0.001-0.005%, Ba: 0.003%, Cu: 0.05%, the balance is Fe and unavoidable impurities .

[0034] (2) The number of times of rough rolling is 4 times, and the reduction rate of each pass is controlled below 35%; after rough rolling, high-pressure water is turned on to remove phosphorus, and the phosphorus removal pressure is 18MPa;

[0035] (3) Finish rolling: use KOCKS three-roller reducing sizing unit for rolling, set the temperature into KOCKS to be 840°C...

Embodiment 3

[0039](1) Weigh the components of each raw material, mix the materials, smelt them, and cast them into billets; use a high-efficiency walking beam heating furnace for hot rolling; the preheating section is ≤850°C, the heating section is 1280°C, and the soaking section is 1380°C , heat preservation 90min; start rolling temperature 1150°C, total billet heating time 180min; use the following components by weight as raw materials: C: 0.4%, Cr: 10.5%, Al: 3.5%, N: 0.8%, Nb : 0.05%, V: 0.12%, Mo: 0.16%, Mn: 4.5%, Si: 0.3%, S: 0.001-0.005%, Ba: 0.005%, Cu: 0.08%, the balance is Fe and unavoidable impurities .

[0040] (2) The number of times of rough rolling is 6 times, and the reduction rate of each pass is controlled below 35%; after rough rolling, high-pressure water is turned on to remove phosphorus, and the phosphorus removal pressure is 18MPa;

[0041] (3) Finish rolling: KOCKS three-roller reducing and sizing unit is used for rolling, the temperature of entering KOCKS is set ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electric potential / voltage | aaaaa | aaaaa |

| electric potential / voltage | aaaaa | aaaaa |

| electric potential / voltage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com