Elevator furnace nitrogen purification cycle utilization device and process

A gas purification device and purification cycle technology, applied in the direction of bell-type furnaces, furnaces, furnace components, etc., can solve the problems of atmospheric environment and working environment pollution, particles and heat residues, lubricant residues, etc., to improve the working environment, Effects of reducing pollution and reducing safety accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

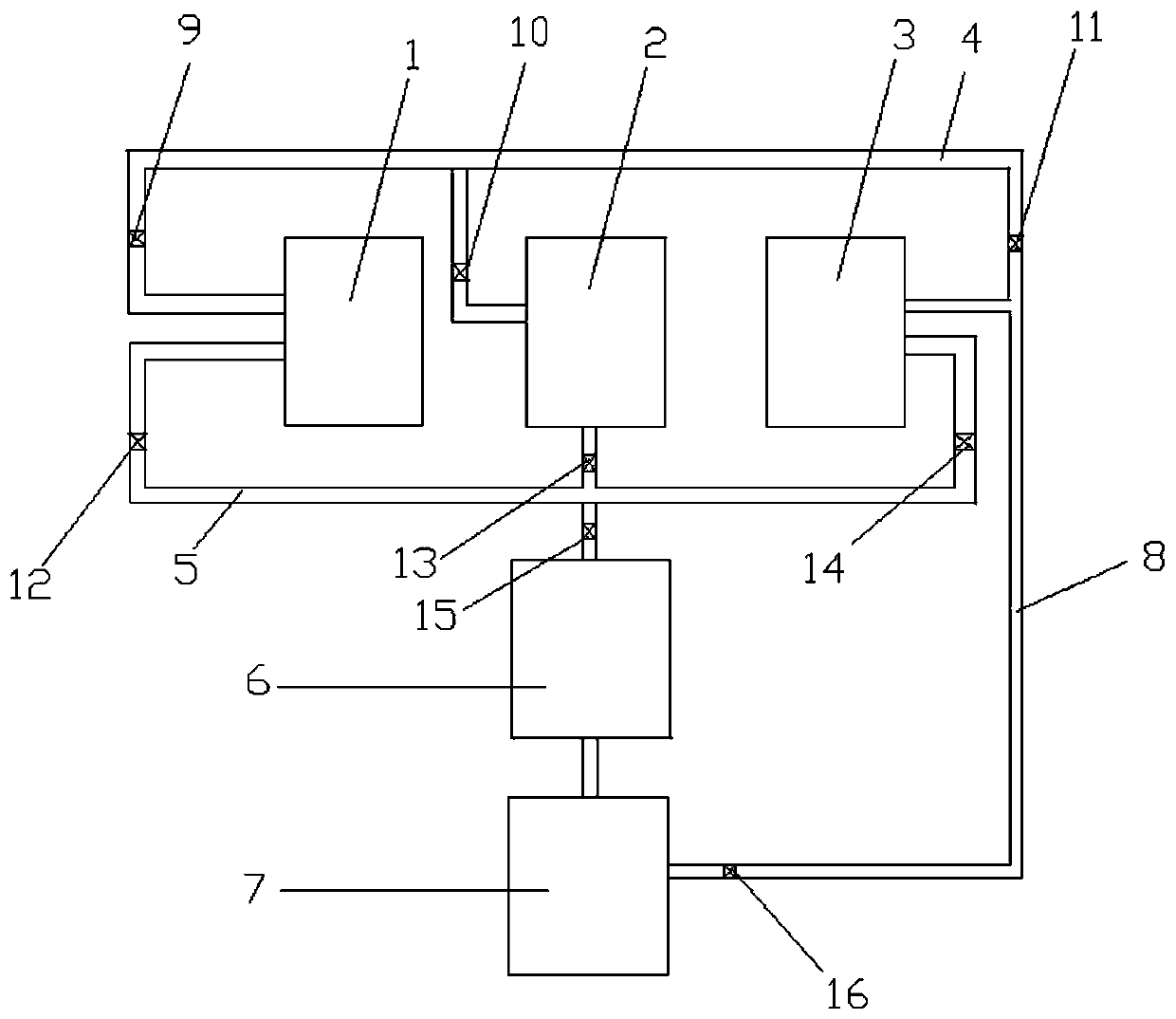

[0023] A bell furnace nitrogen purification and recycling device, wherein: it includes a bell furnace, a gas purification device and a gas storage tank; the bell furnace includes a heating cover and a plurality of furnace seats, each of which is provided with a Furnace: the furnace includes the first furnace 1, the second furnace 2 and the third furnace 3; the heating mantle can be respectively arranged on the first furnace 1, the second furnace 2 and the third furnace 3 outside; the input ends of the first furnace 1, the second furnace 2 and the third furnace 3 are respectively connected with the first gas pipeline 4; the first furnace 1, the second furnace 2 and the first furnace The output ends of the three furnaces 3 are respectively connected with a second gas pipeline 5; the other end of the second gas pipeline 5 is connected with a gas purification device 6; the other end of the gas purification device 6 is connected with a gas storage tank 7 The other end of the gas st...

Embodiment 2

[0031] A bell furnace nitrogen purification recycling process, wherein: comprising the following steps:

[0032] 1) Put the coil to be annealed into the material frame and then put it into the bell furnace base, cover the first furnace or the second furnace or the third furnace and seal it, vacuumize and fill the furnace with nitrogen to the pressure inside the furnace To 0.1 ~ 0.12MPa, cover the heating mantle, connect the cooling water and power supply, turn on the power supply for annealing;

[0033] 2) During the annealing process and after annealing, the nitrogen mixture containing oil gas and carbon dust in the first furnace or the second furnace or the third furnace enters the gas purification device through the second gas pipeline for purification to obtain clean Nitrogen;

[0034] 3) Pass the purified clean nitrogen into the gas storage tank for buffering;

[0035] 4) The clean nitrogen buffered in the gas storage tank is passed through the third gas pipeline into t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com