A preparation method and purification process of lithium fluorine-containing sulfonylimide

A lithium sulfonyl imide and process technology, which is applied in the field of preparation of fluorine-containing lithium sulfonyl imide, can solve the problems of cumbersome preparation methods, low product yield, and high product impurities, and achieve low raw material cost, high purity, and low cost. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

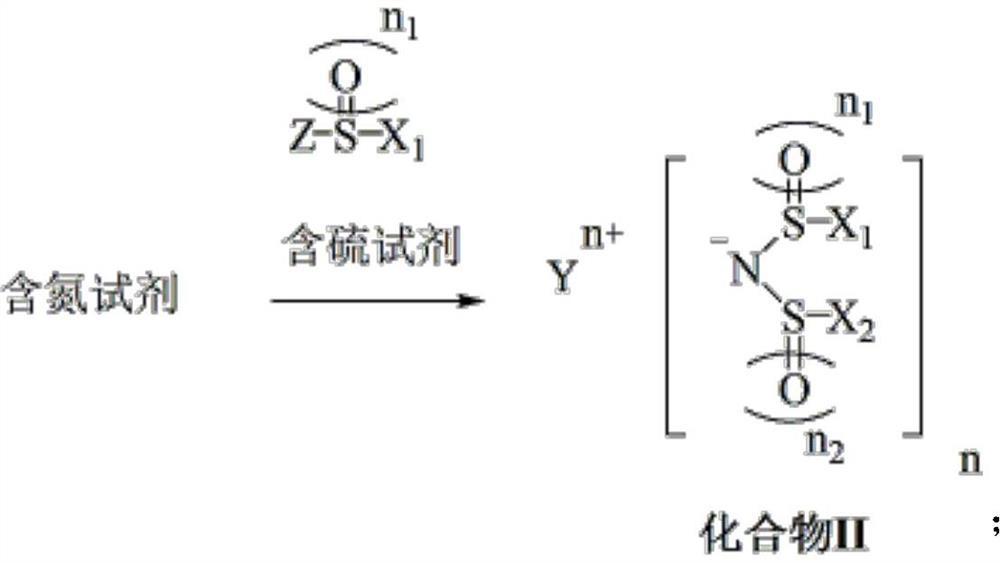

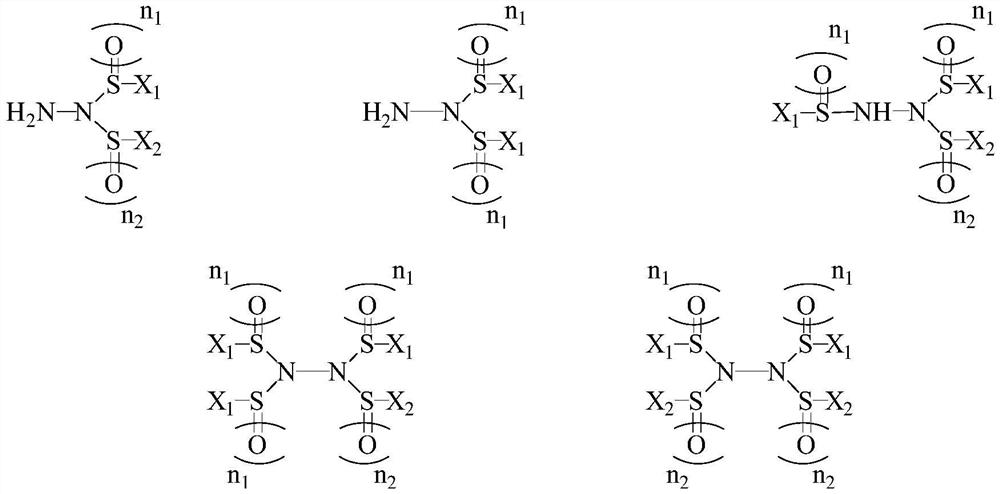

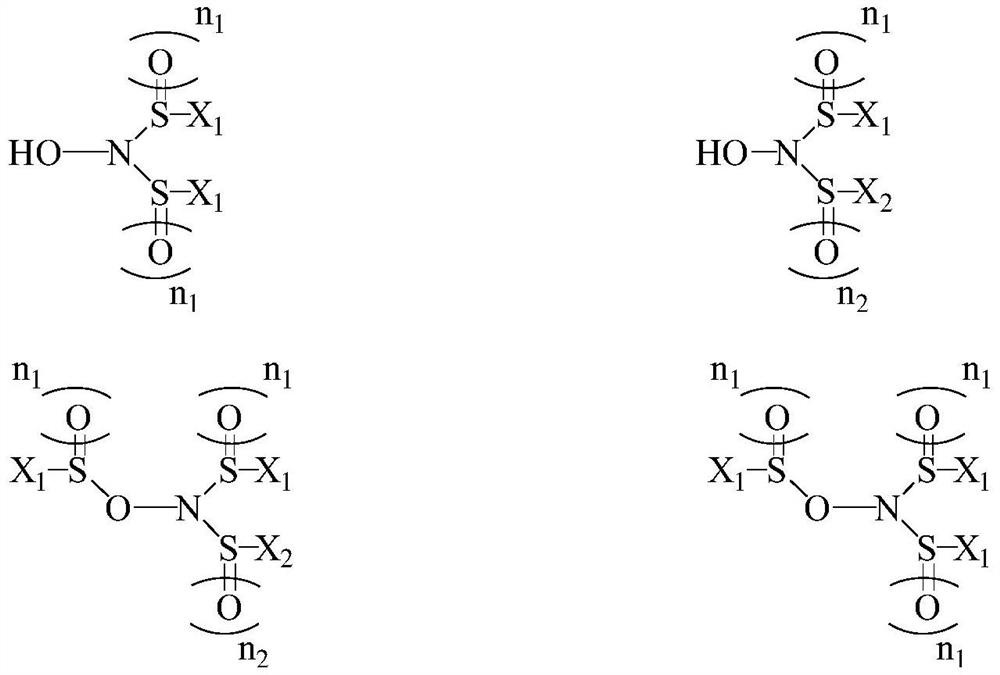

Method used

Image

Examples

Embodiment 1

[0066] The preparation method and purification process of lithium bistrifluoromethanesulfonimide, comprising the following steps:

[0067] (1) Preparation process one:

[0068] Under stirring conditions, 100 g of nitrogen-containing substance trifluoromethylsulfonyl chloride, isopropanol, and reaction solvent toluene were added to a 1L dry reactor, and the molar ratios of sulfur-containing substance trifluoromethylsulfinyl chloride and isopropanol were respectively is 2.5:1, the reaction temperature is 70°C, the reaction pressure is 0.1MPa (gauge pressure), and the reaction time is 4h. After the reaction is completed, it is lowered to normal temperature, the insolubles are filtered off, the filtrate is evaporated under reduced pressure to remove the solvent, and concentrated to prepare a crude product of compound II;

[0069] (2) preparation process two:

[0070] Under stirring conditions, 100 g of compound II and reaction solvent toluene were added to a 1L dry reactor, and ...

Embodiment 2

[0078] The preparation method and purification process of lithium bisfluorosulfonimide, comprising the following steps:

[0079] (1) Preparation process one:

[0080] Under stirring conditions, 100 g of nitrogen-containing substance trifluoromethylsulfonyl chloride, isopropanol, and reaction solvent toluene were added to a 1L dry reactor, and the molar ratios of sulfur-containing substance trifluoromethylsulfinyl chloride and isopropanol were respectively is 2.5:1, the reaction temperature is 70°C, the reaction pressure is 0.1MPa (gauge pressure), and the reaction time is 4h. After the completion of the reaction, the temperature was lowered to normal temperature. The insolubles were removed by filtration, the filtrate was evaporated under reduced pressure to remove the solvent, and concentrated to obtain the crude product of compound II;

[0081] (3) preparation process two:

[0082] Under stirring conditions, 100 g of compound II and reaction solvent toluene were added to ...

Embodiment 3

[0090] Preparation and purification process of lithium bis(perfluoroethylsulfonyl)imide

[0091] (1) Preparation process one:

[0092] Under stirring conditions, 100 g of nitrogen-containing substances perfluoroethylsulfonyl chloride, isopropanol, and reaction solvent toluene were added to a 1L dry reactor, and the molar ratios of sulfur-containing substances perfluoroethylsulfinyl chloride and butyl acetate were respectively is 3:1, the reaction temperature is 80°C, the reaction pressure is 0MPa (gauge pressure), and the reaction time is 6h. After the reaction is completed, it is lowered to normal temperature, the insolubles are filtered off, the filtrate is evaporated under reduced pressure to remove the solvent, and concentrated to prepare a crude product of compound II;

[0093] (2) preparation process two:

[0094] Under stirring conditions, 100 g of compound II and butyl acetate as the reaction solvent were added to a 1L dry reactor, and the fluorine-containing reagent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com