Magnetic powder modified polyferric chloride coagulant and preparation method thereof

A technology of polymerizing ferric chloride and coagulant, which is applied in chemical instruments and methods, magnetic field/electric field water/sewage treatment, flocculation/sedimentation water/sewage treatment, etc. It can solve the problems of unstable dispersion and reduce agglomeration , Improve removal efficiency, increase the effect of precipitation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

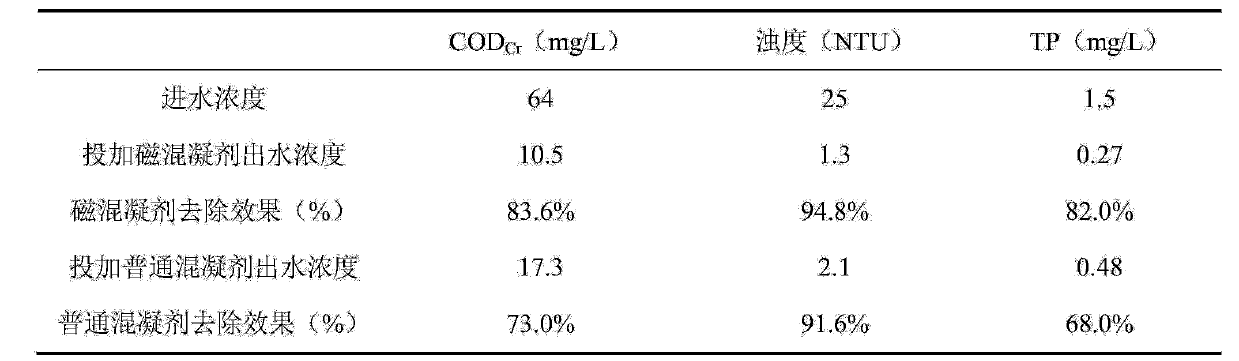

Embodiment 1

[0024] A kind of magnetic powder modified polyferric chloride coagulant of the present invention is obtained through the following process steps:

[0025] 1) prepare polyferric chloride solution, solution concentration 10g / L;

[0026] 2) Prepare polyacrylamide solution by ultrasonic + stirring method, the solution concentration is 10g / L;

[0027] 3) prepare EDTA-2Na solution, the solution concentration is 10g / L;

[0028] 4) Take 100mL of polyferric chloride solution with a concentration of 10g / L, pour it into a conical flask, add 2g of nano-magnetic Fe 3 o 4 Powder, so that the mass ratio of magnetic powder to ferric chloride is 2:1, stirred at 25°C for 30min, and the stirring rate is 120rpm;

[0029] 5) On the basis of step 4), take 10mL of polyacrylamide solution with a concentration of 10g / L, add it into the Erlenmeyer flask, stir at 25°C for 30min, and the stirring rate is 100rpm;

[0030] 6) On the basis of step 5), take 10mL of EDTA-2Na solution with a concentration ...

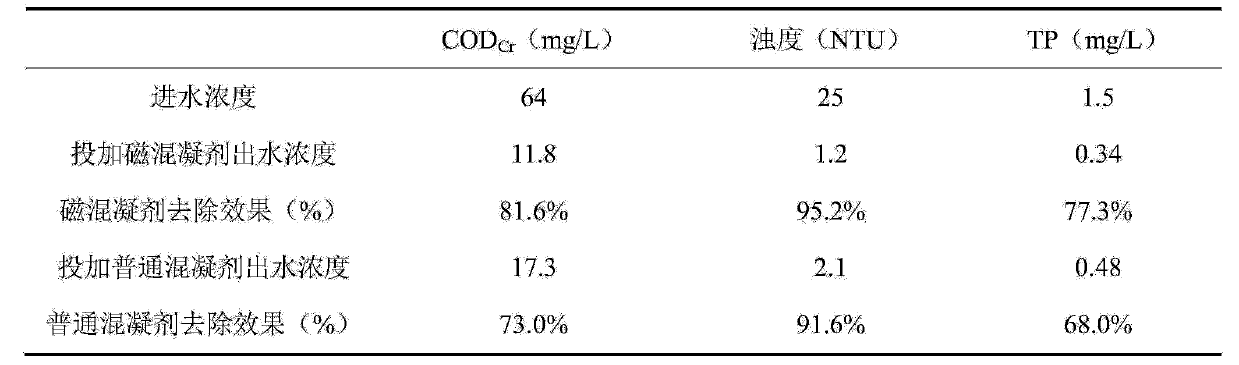

Embodiment 2

[0037] A kind of magnetic powder modified polyferric chloride coagulant of the present invention is obtained through the following process steps:

[0038] 1) prepare polyferric chloride solution, solution concentration 10g / L;

[0039] 2) Prepare polyacrylamide solution by ultrasonic + stirring method, the solution concentration is 10g / L;

[0040] 3) prepare EDTA-2Na solution, the solution concentration is 10g / L;

[0041] 4) Take 100mL of polyferric chloride solution with a concentration of 10g / L, pour it into a conical flask, add 3g of nano-magnetic Fe 3 o 4 powder, so that the mass ratio of magnetic powder to ferric chloride is 3:1, stirred at 25°C for 30min, with a stirring rate of 120rpm;

[0042] 5) On the basis of step 4), take 20mL of a polyacrylamide solution with a concentration of 10g / L, add it to a conical flask, and stir at 25°C for 30min at a stirring rate of 100rpm;

[0043] 6) On the basis of step 5), take 20 mL of EDTA-2Na solution with a concentration of 10...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com