Composite biological degreasing agent and application thereof

A degreasing agent and biological technology, applied in the field of leather degreasing, can solve the problems of incomplete degreasing, oily frost on the leather surface, low degreasing rate of acid lipase, etc., and achieve the effect of reducing pollution and reducing dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] The preparation process of the composite biological degreasing agent of present embodiment 1 is as follows:

[0042] The compound biological degreasing agent of present embodiment 1 comprises the component of following weight portion:

[0043] 20 parts of acid lipase;

[0044] Nonionic surfactant: 20 parts of BASF TO-8;

[0045] Enzyme activator: 0.1 parts of calcium chloride;

[0046] Enzyme stabilizer: 8 parts of propylene glycol, 2.5 parts of 4-formylphenylboronic acid (4-FPBA);

[0047] pH stabilizer: 4.5 parts of sodium citrate;

[0048] Preservative: 0.1 parts of Kasong;

[0049] The rest is water.

[0050] Mix the above components uniformly to obtain the acid lipase-based composite biological degreasing agent of the present embodiment 1.

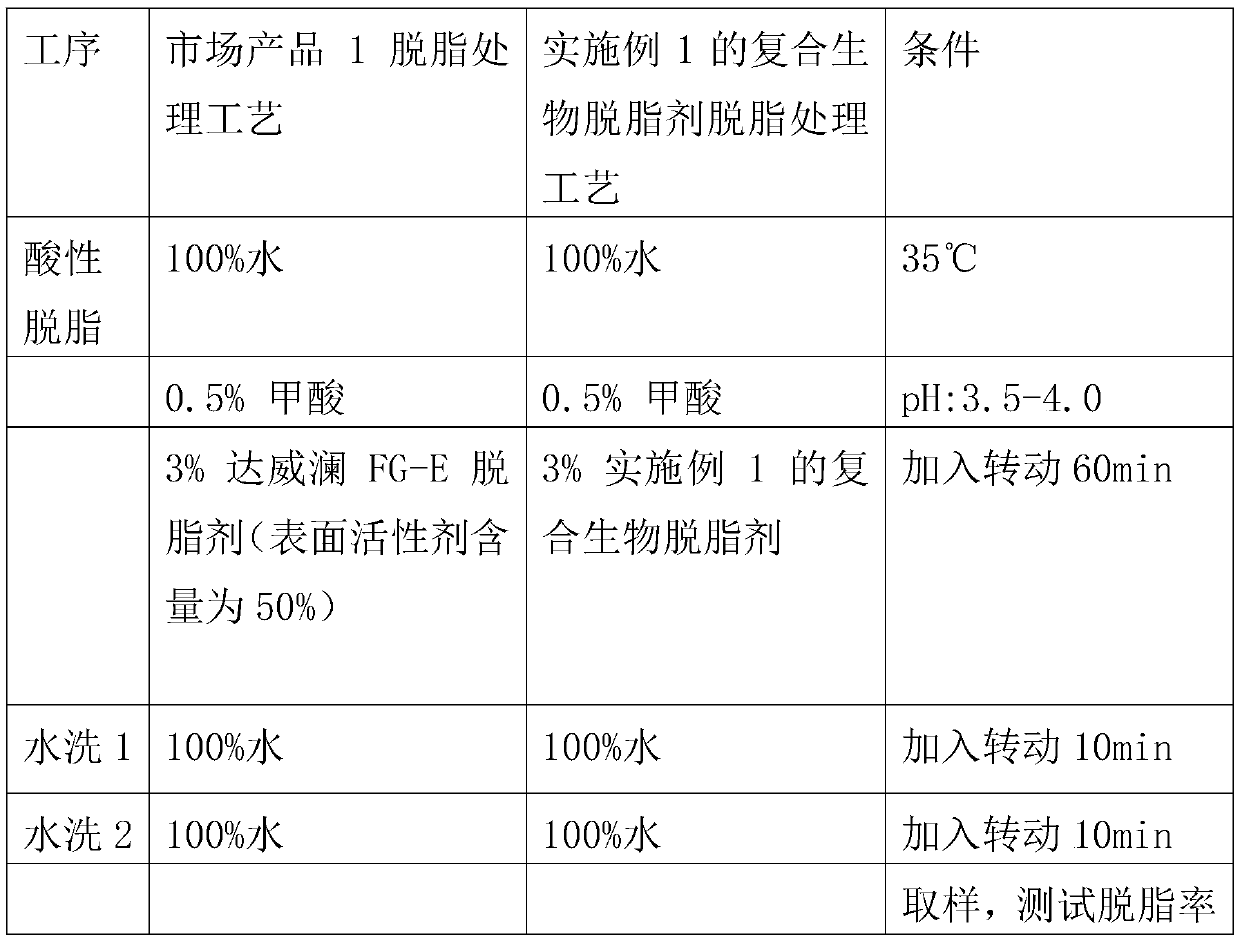

[0051] Table 1 shows the application of the compound biological degreasing agent prepared in Example 1 and the market product 1 as a comparative experiment to the degreasing treatment process of sheep wet blue hide rich i...

Embodiment 2

[0059] The preparation process of the composite biological degreasing agent of present embodiment 2 is as follows:

[0060] The compound biological degreasing agent of present embodiment 2 comprises the component of following weight portion:

[0061] 25 parts of acid lipase;

[0062] Nonionic surfactant: 20 parts of BASF XL-90;

[0063] Enzyme activator: 0.15 parts of calcium chloride;

[0064] Enzyme stabilizer: 8.5 parts of propylene glycol, 3.0 parts of 4-formylphenylboronic acid (4-FPBA);

[0065] pH stabilizer: 5 parts of sodium citrate;

[0066] Preservative: 0.1 parts of Kasong;

[0067] The rest is water.

[0068] Mix the above components evenly to obtain the acid lipase-based composite biological degreasing agent of the present embodiment 2.

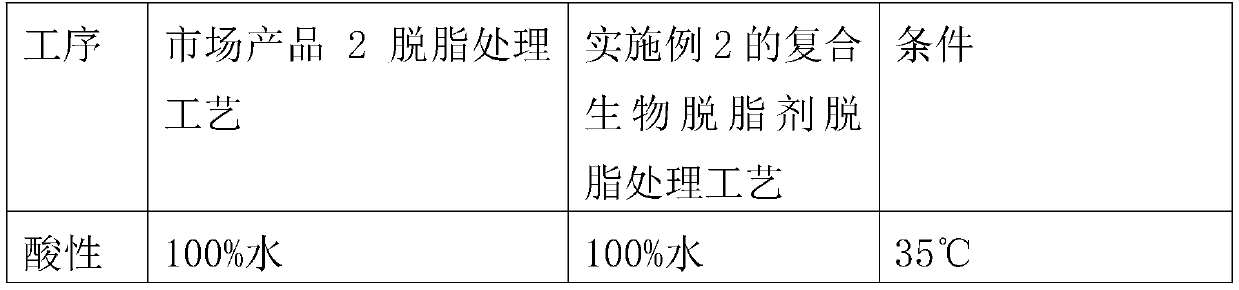

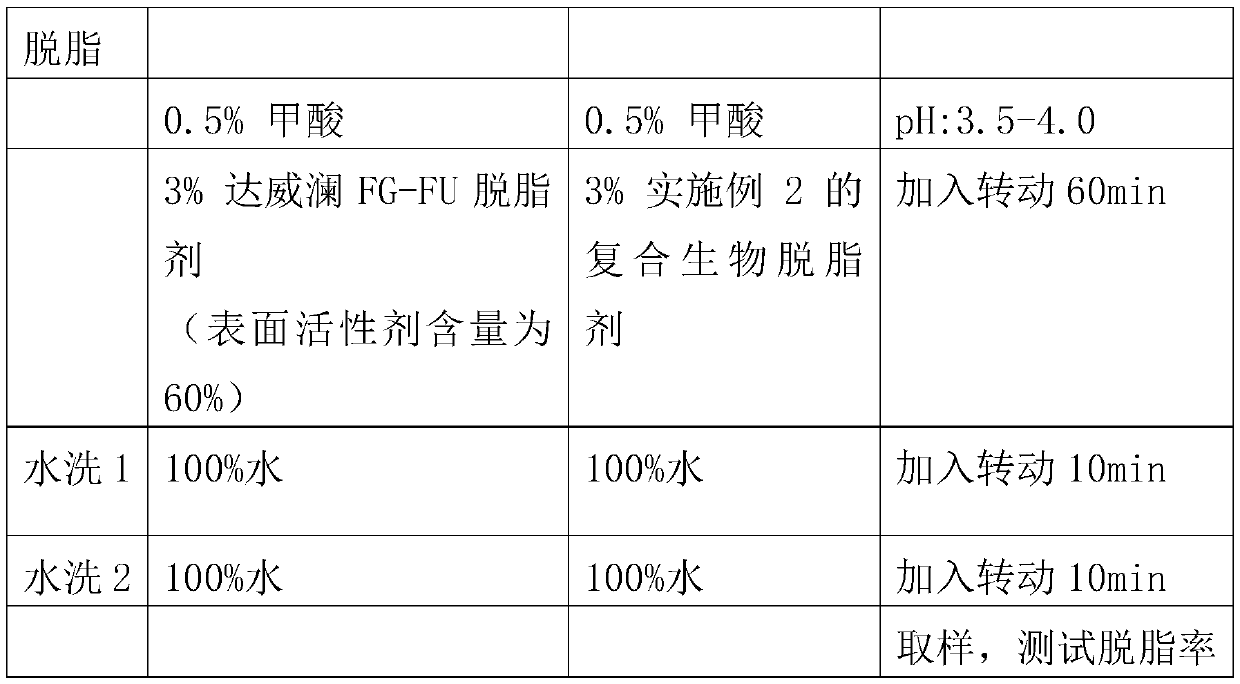

[0069] Table 3 shows that the compound biological degreasing agent prepared in Example 2 and the market product 2 were used as a comparative experiment in the degreasing process of sheep wet blue hide rich in oil. Among the...

Embodiment 3

[0078] The preparation process of the composite biological degreasing agent of present embodiment 3 is as follows:

[0079] The composite biological degreasing agent of present embodiment 3 comprises the component of following weight portion:

[0080] 15 parts of acid lipase;

[0081] Nonionic surfactant: 25 parts of BASF AEO-9;

[0082] Enzyme activator: 0.1 parts of calcium chloride;

[0083] Enzyme stabilizer: 7.5 parts of propylene glycol, 2.0 parts of 4-formylphenylboronic acid (4-FPBA);

[0084] pH stabilizer: 4 parts of sodium citrate;

[0085] Preservative: 0.1 parts of Kasong;

[0086] The rest is water.

[0087] Mix the above components evenly to obtain the acid lipase-based composite biological degreasing agent of the present embodiment 3.

[0088] Table 5 shows that the composite biological degreasing agent prepared in Example 3 and the market product 3 were used as a comparative experiment in the degreasing process of wet blue sheep hides rich in oil. Among...

PUM

| Property | Measurement | Unit |

|---|---|---|

| skim rate | aaaaa | aaaaa |

| skim rate | aaaaa | aaaaa |

| skim rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com