Cobalt-free lithium-rich manganese-based positive electrode material, composite positive electrode sheet and lithium ion battery

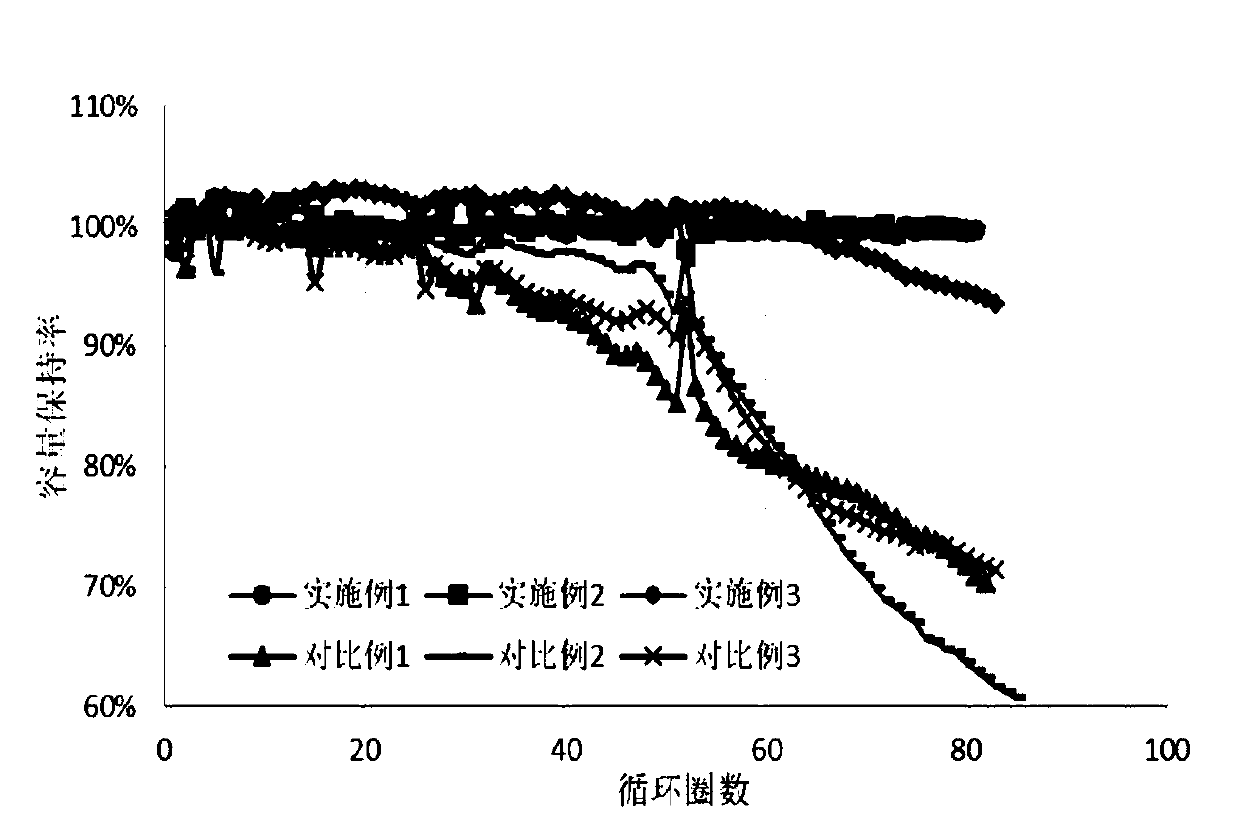

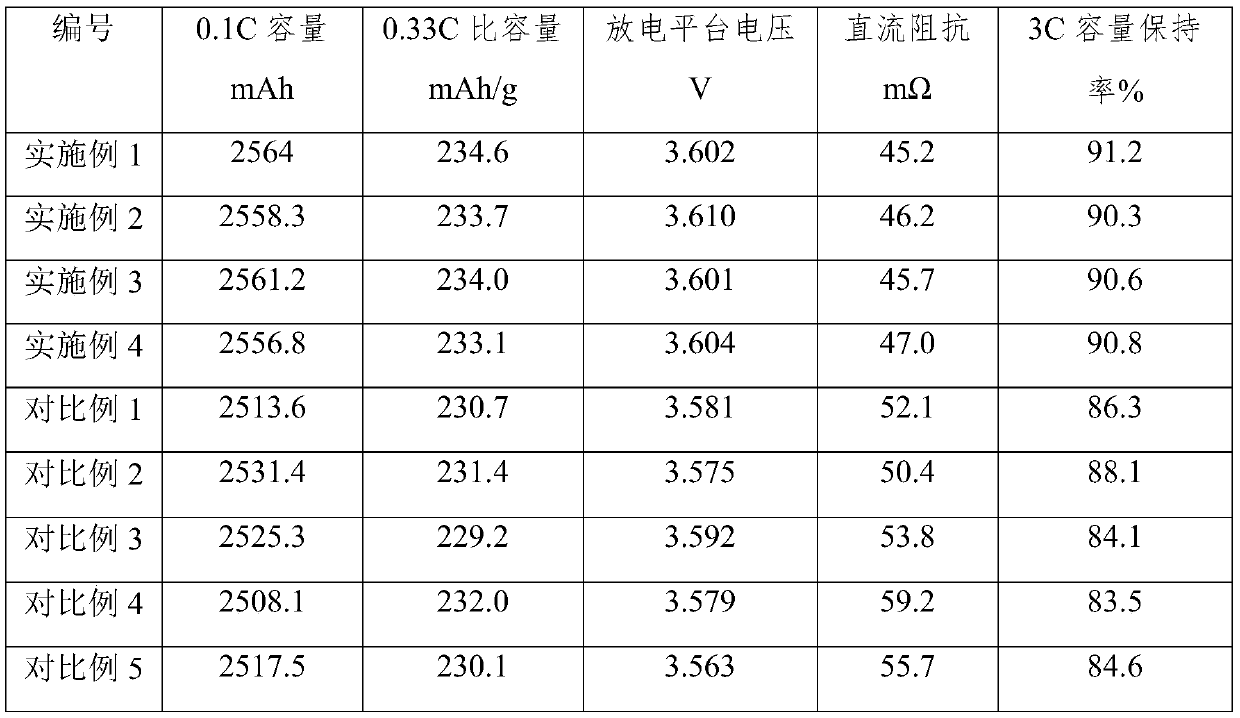

A technology for cobalt, lithium-rich manganese-based, and lithium-ion batteries, which is applied in battery electrodes, secondary batteries, circuits, etc., and can solve the problems of low stability of lithium-rich manganese-based cathode materials, no commercial application value, and rapid voltage decay. , to achieve the effects of good cycle stability, slow voltage decay and high first efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0060] The preparation of the composite positive pole piece comprises the steps:

[0061] (1) Weigh 0.32kg of conductive carbon black, 0.34kg of polyvinylidene fluoride and 0.01kg of dispersant into a high-speed disperser, the dispersion speed is 2000rpm, and the dispersion time is 1.5h;

[0062] (2) Continue to add 6.72kg of N-methyl-2-pyrrolidone, then add 4.95kg of cobalt-free lithium-rich manganese-based active material, the dispersion speed is 3500rpm, the dispersion time is 3.5h, and the slurry is uniformly mixed;

[0063] (3) Continue to add 4.9kg of cobalt-free lithium-rich manganese-based active materials and 0.2kg of N-methyl-2-pyrrolidone into the high-speed disperser, adjust the dispersion speed to 3500rpm, and the dispersion time to 2.5h to obtain a composite positive electrode slurry;

[0064] (4) Pump the above-mentioned composite positive electrode slurry to the coating machine through the pipeline, adjust the setting parameters to the specified thickness and c...

Embodiment 2

[0072] The preparation of the composite positive pole piece comprises the steps:

[0073] (1) Weigh 0.3kg of conductive carbon black, 0.2kg of polyvinylidene fluoride and 0.1kg of dispersant into a high-speed disperser, the dispersion speed is 2000rpm, and the dispersion time is 1.5h;

[0074] (2) Continue to add 6.72kg of N-methyl-2-pyrrolidone, then add 4.7kg of cobalt-free lithium-rich manganese-based active material, the dispersion speed is 3500rpm, the dispersion time is 3.5h, and the slurry is uniformly mixed;

[0075] (3) Continue to add 4.7kg of cobalt-free lithium-rich manganese-based active materials and 0.2kg of N-methyl-2-pyrrolidone into the high-speed disperser, adjust the dispersion speed to 3500rpm, and the dispersion time to 2.5h to obtain a composite positive electrode slurry;

[0076] (4) Pump the above-mentioned composite positive electrode slurry to the coating machine through the pipeline, adjust the setting parameters to the specified thickness and coat ...

Embodiment 3

[0084] The preparation of composite positive electrode sheet comprises the steps:

[0085] (1) Weigh 0.4kg of conductive carbon black, 0.35kg of polyvinylidene fluoride and 0.1kg of dispersant into a high-speed disperser, the dispersion speed is 2000rpm, and the dispersion time is 1.5h;

[0086] (2) Continue to add 6.72kg of N-methyl-2-pyrrolidone, then add 4.85kg of cobalt-free lithium-rich manganese-based active material, the dispersion speed is 3500rpm, the dispersion time is 3.5h, and the slurry is uniformly mixed;

[0087] (3) Continue to add 4.8 kg of cobalt-free lithium-rich manganese-based active materials and 0.2 kg of N-methyl-2-pyrrolidone into the high-speed disperser, adjust the dispersion speed to 3500 rpm, and the dispersion time to 2.5 hours to obtain a composite positive electrode slurry;

[0088] (4) Pump the above-mentioned composite positive electrode slurry to the coating machine through the pipeline, adjust the setting parameters to the specified thicknes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com