Rust-proof steel plate for vehicle in high-humidity environment and manufacturing process thereof

A high-humidity, steel plate technology, applied to bicycles, motor vehicles, anti-corrosion coatings, etc., can solve problems that affect service life and product quality, steel plate rust, corrosion, etc., to improve anti-corrosion effect, improve product quality, and not easy Shedding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in detail below in conjunction with various embodiments shown in the drawings. However, these embodiments do not limit the present invention, and structural, method, or functional changes made by those skilled in the art according to these embodiments are included in the protection scope of the present invention.

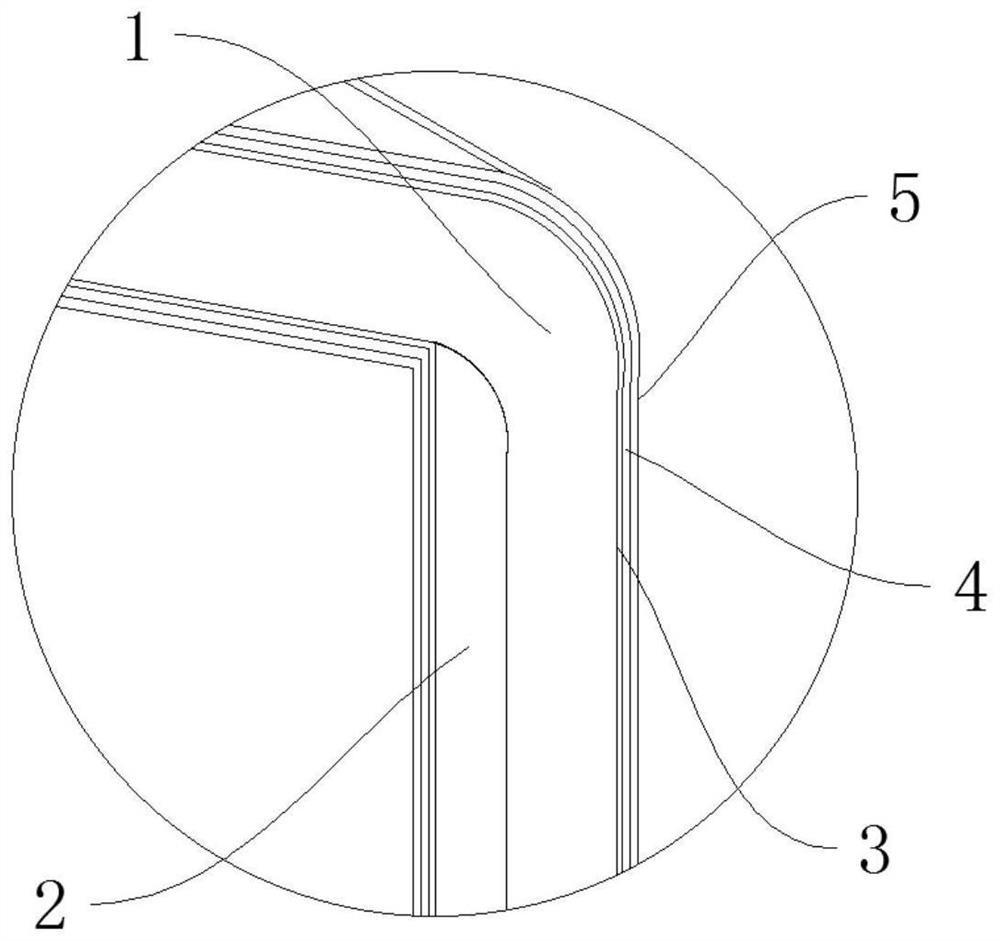

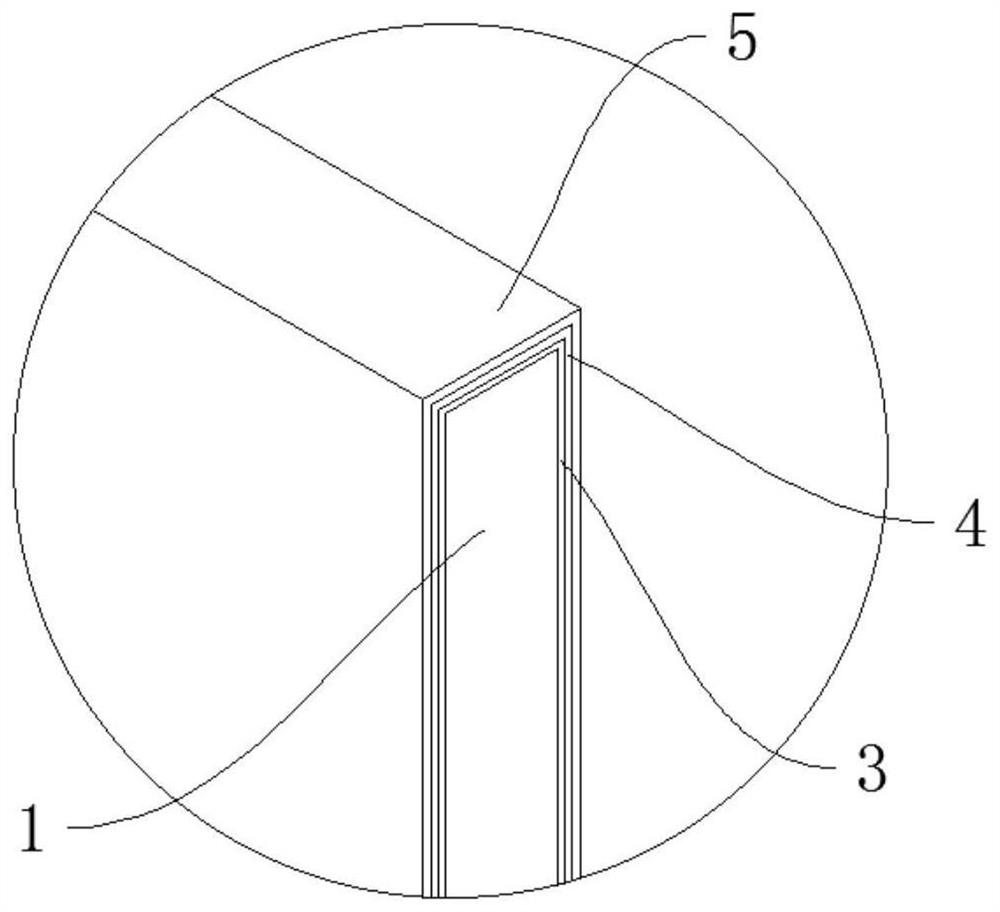

[0031] The invention discloses an antirust vehicle steel plate used in a high humidity environment and its manufacturing process, including an antirust steel plate assembly, the antirust steel plate assembly includes a steel plate 1 and a zinc strip 2, and the steel plate 1 is a conventionally used steel plate, preferably Specifically, the steel plate 1 is a galvanized steel plate, the type of the galvanized steel plate is a hot-dip galvanized steel plate, the production cost is relatively low, and the corrosion resistance is good.

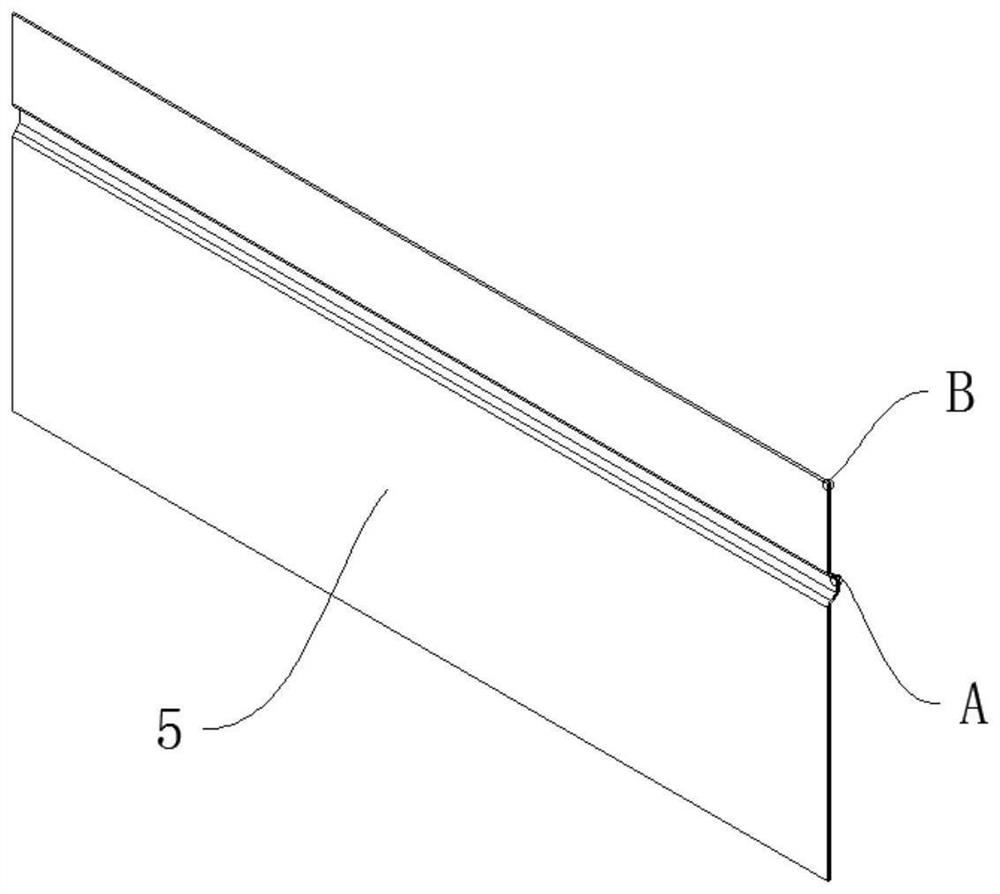

[0032] ginseng Figure 1 to Figure 5 As shown, the steel plate 1 is provided with a re...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap