Preparation method of energy storage carbon material, supercapacitor and energy storage carbon material

A carbon material, energy storage technology, applied in hybrid capacitor electrodes, chemical instruments and methods, carbon compounds, etc. problems, to achieve the effect of reducing the preparation cost, improving the specific capacity and rate performance, and improving the specific capacity and rate performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

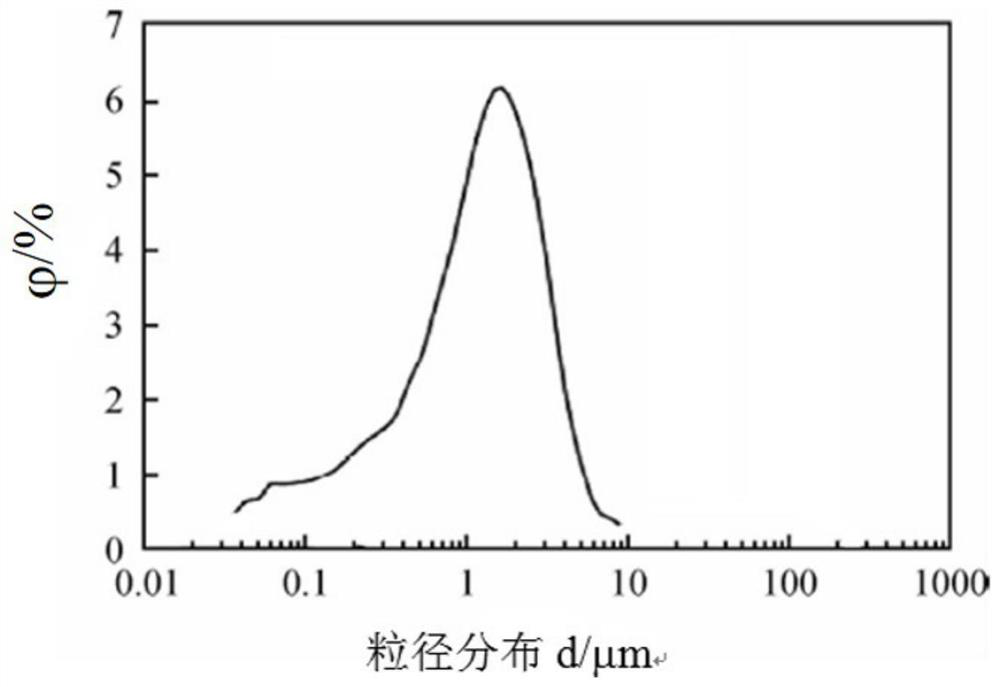

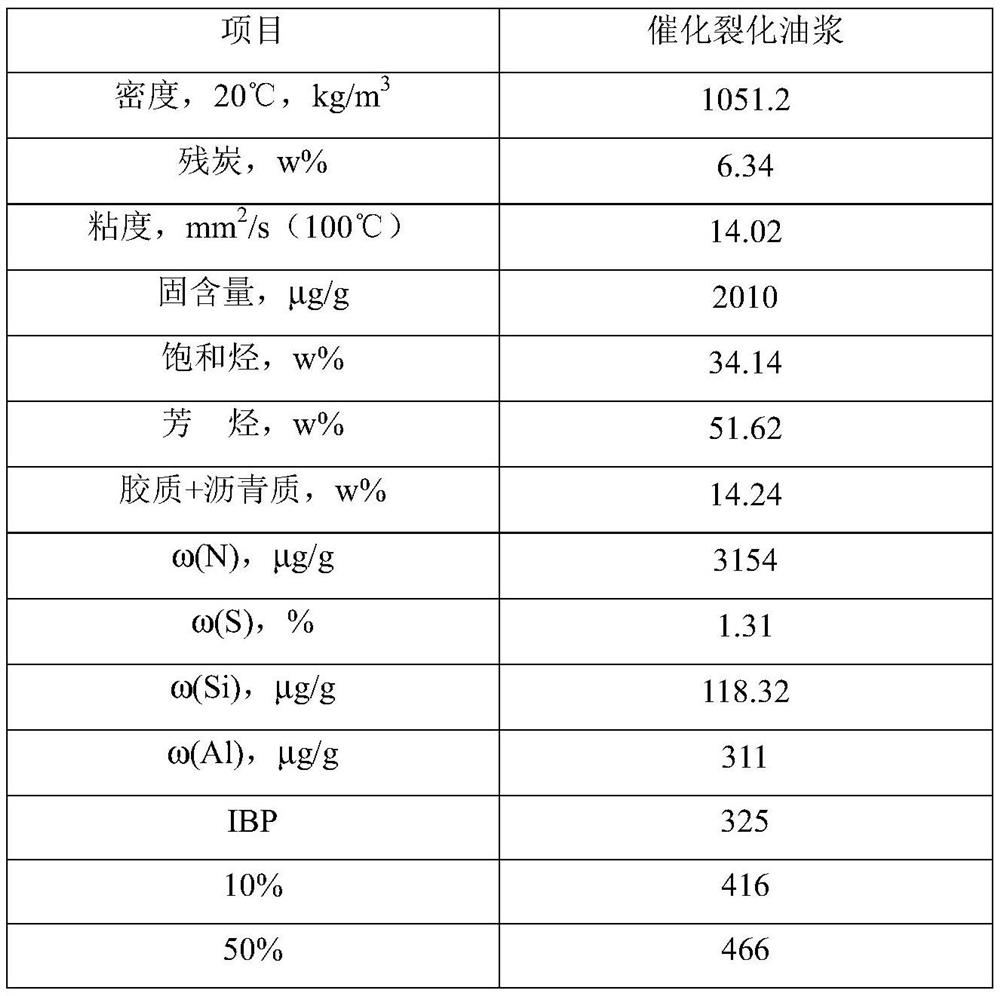

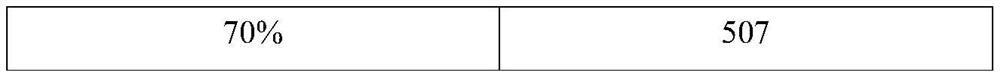

[0039] This embodiment provides a method for preparing energy storage carbon materials using catalytic cracking oil slurry, which includes using catalytic oil slurry with the composition properties shown in Table 1 as a raw material, and the particle size distribution of the raw material is referred to figure 1 shown. Carry out carbonization activation under a nitrogen atmosphere, use SP80 as a surfactant, and the addition amount is 2% of the mass of the raw material catalytic oil slurry. In this embodiment, potassium hydroxide is used as the alkaline reagent, and the addition amount of the alkaline reagent is the mass of the raw material catalytic oil slurry. 30% of. In this embodiment, the first-stage carbonization activation is not performed, and the second-stage carbonization activation temperature is set to 700° C., and the carbonization activation reaction time is 2 hours.

[0040] Table 1 Main properties of catalytic cracking feedstock.

[0041]

[0042]

Embodiment 2

[0044]This embodiment provides a method for preparing energy storage carbon materials by using catalytic cracking oil slurry. The raw material composition and particle size distribution are the same as those in Embodiment 1. Carry out carbonization activation under nitrogen atmosphere, with SP80 surface active agent, add-on is 5% of raw material catalytic oil slurry addition quality, present embodiment uses potassium hydroxide as alkali reagent, and the add-on of alkaline reagent is raw material catalytic oil slurry quality. 60%. In this embodiment, the first-stage carbonization activation is not performed, and the second-stage carbonization activation temperature is set to 700° C., and the carbonization activation reaction time is 2 hours.

Embodiment 3

[0046] Compared with the method for preparing energy storage carbon materials provided in Example 1, the only difference is that a carbonization activation step is added before the second-stage carbonization activation reaction, and the temperature of the first-stage carbonization activation reaction is set to 400°C, and the first-stage carbonization activation reaction The time is 0.5h.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com