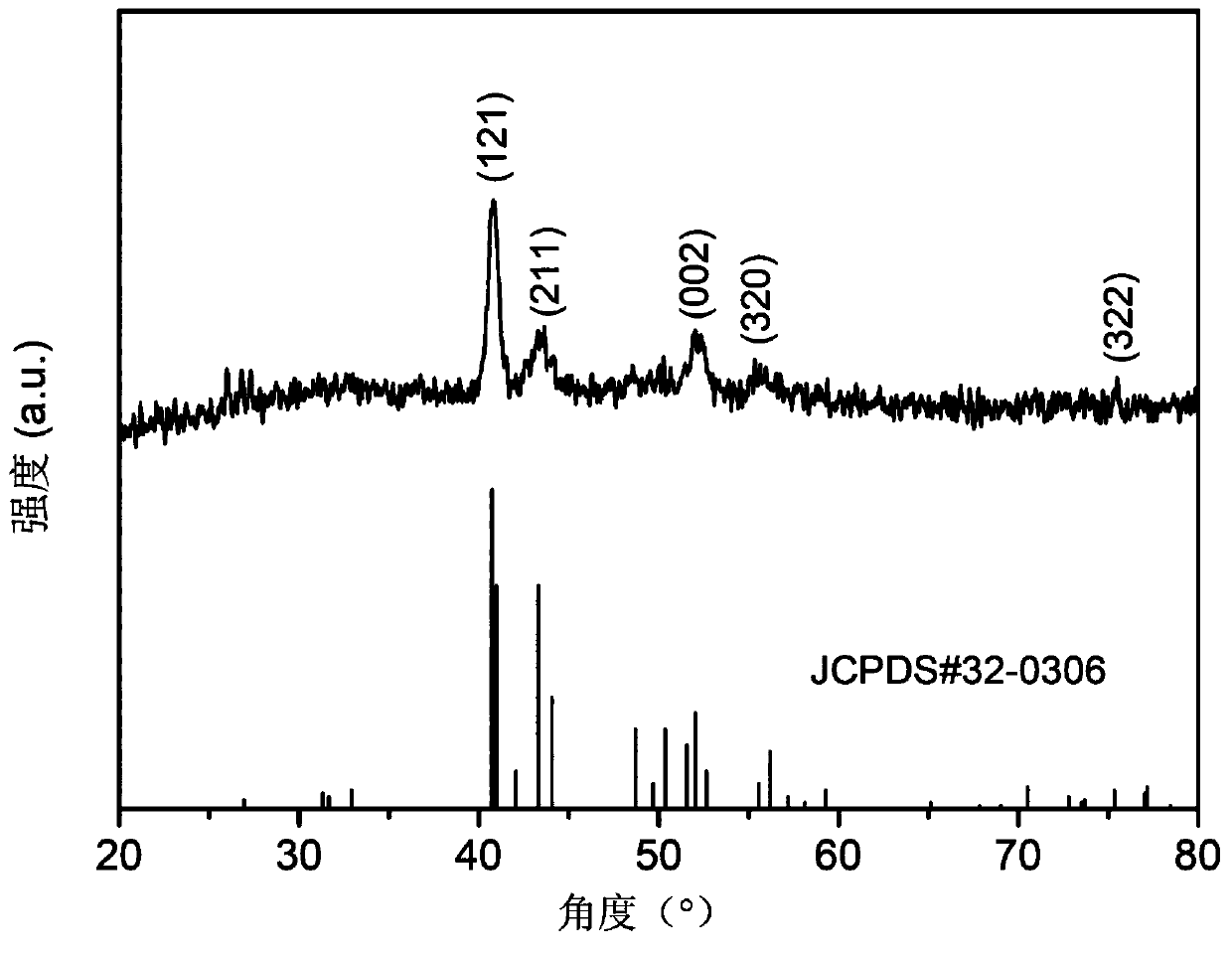

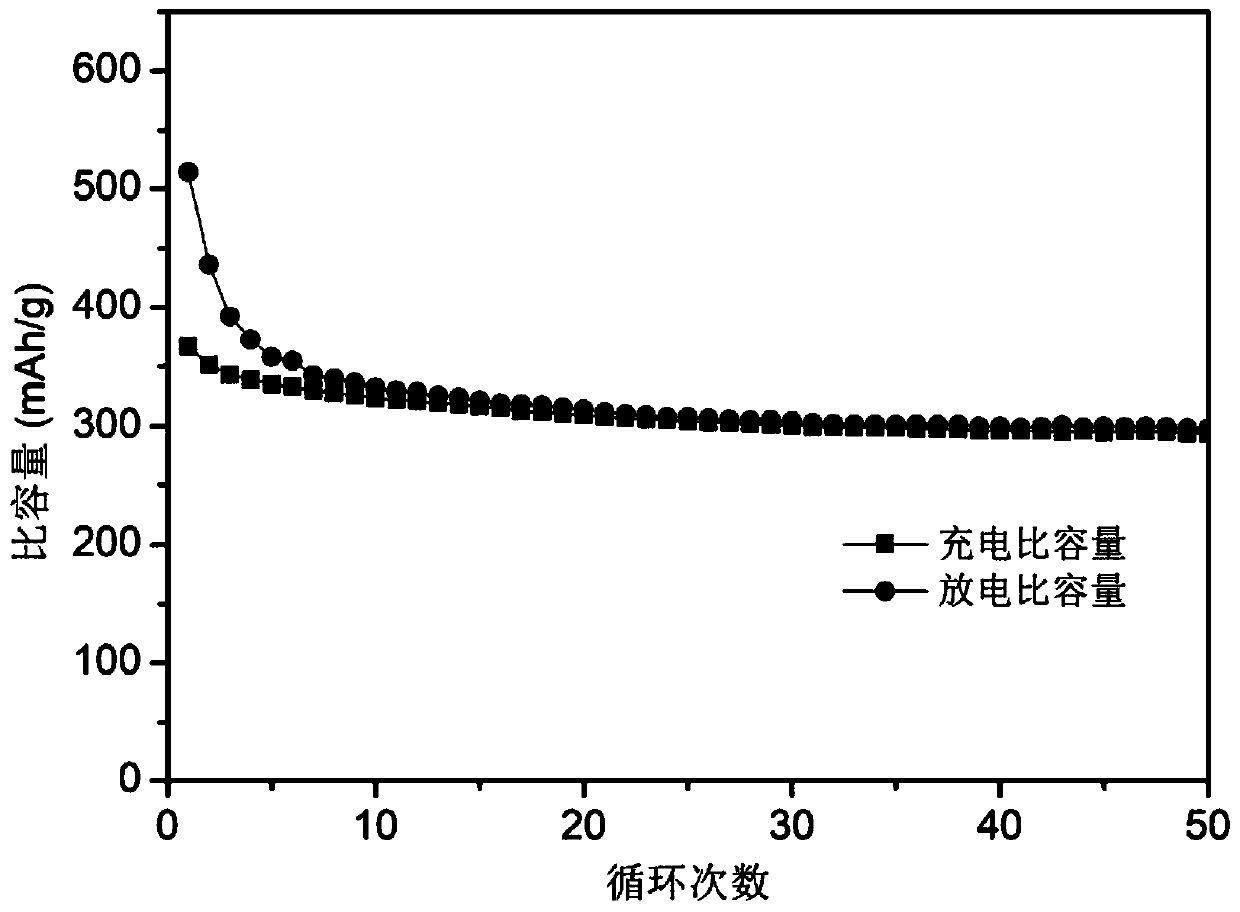

Dicobalt phosphide/carbon composite material, preparation method and use thereof

A carbon composite material, carbon material technology, applied in nanotechnology for materials and surface science, secondary batteries, electrochemical generators, etc. The effect of improving cycle stability and alleviating volume change

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

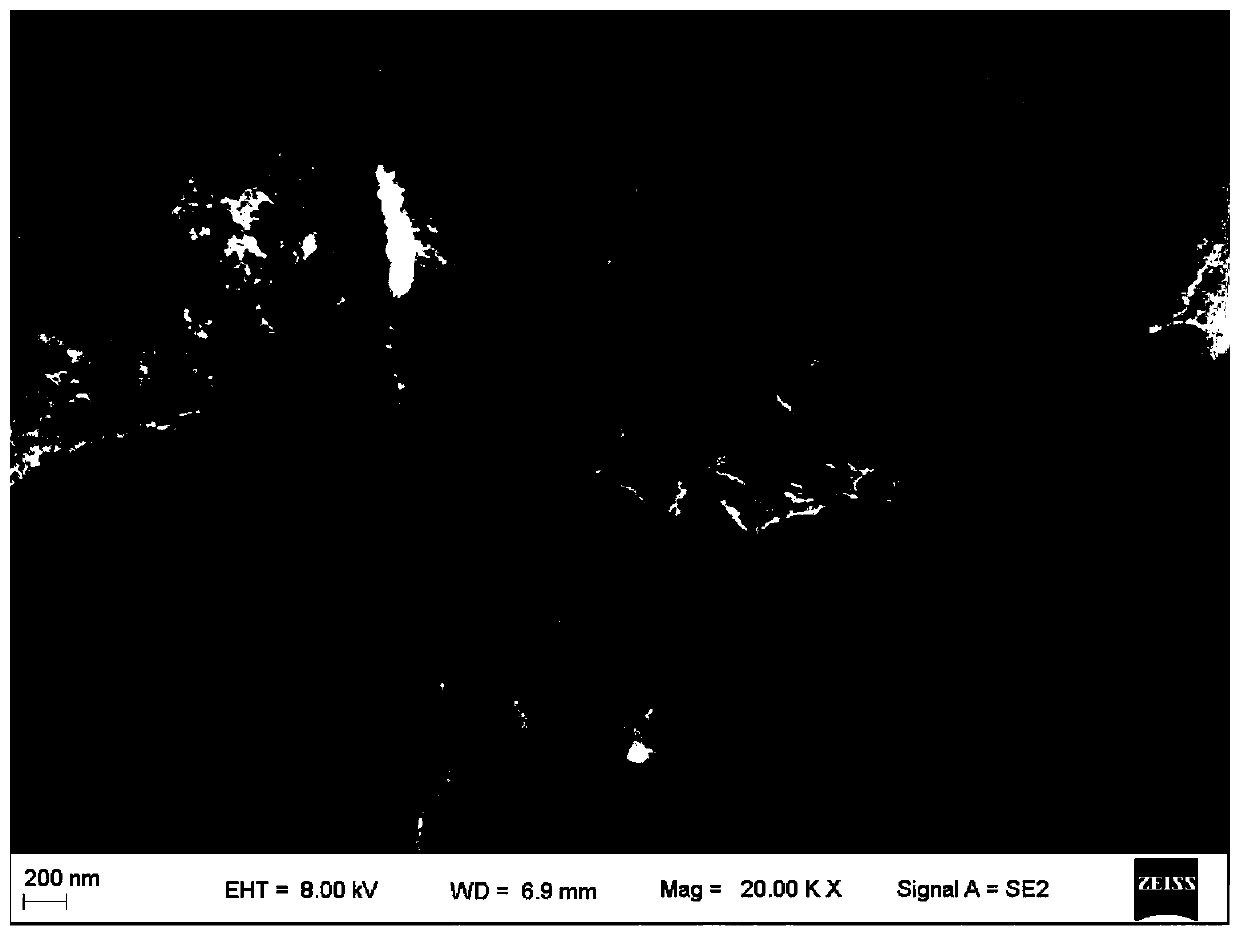

[0072] This embodiment prepares Co according to the following method 2 P / C composite material:

[0073] (1) 0.6112g of Co(NO 3 ) 2 ·6H 2 O, 0.3577g of red phosphorus and 0.05g of CTAB surfactant were added to 35mL of deionized water, and magnetically stirred. The obtained suspension was transferred into a 50 mL Teflon-lined stainless steel autoclave, placed in an oven at 210°C, and reacted for 48 hours to obtain Co 2 P precursor. Then wash twice with 3mol / L hydrochloric acid, then wash several times with deionized water and alcohol, and dry in a drying oven.

[0074] Among them, Co(NO 3 ) 2 ·6H 2 The molar ratio of O to red phosphorus is about 1:5.5, and the concentration of surfactant (CTAB) in the suspension system for hydrothermal reaction is 1.43g / L.

[0075] (2) Then take 1g of dry Co 2 The P precursor was added to a 0.048mol / L glucose solution, then transferred to a 50mL Teflon-lined stainless steel autoclave, placed in an oven at 180°C, and reacted for 3 hours...

Embodiment 2

[0085] This embodiment prepares Co according to the following method 2 P / C composite material:

[0086] (1) 0.6112g of Co(NO 3 ) 2 ·6H 2 O, 0.2927g of red phosphorus and 0.1g of CTAB surfactant were added to 35mL of deionized water, and magnetically stirred. The resulting suspension was transferred to a 50 mL Teflon-lined stainless steel autoclave, placed in an oven at 150 ° C, and reacted for 60 h to obtain Co 2 P precursor. Then wash twice with 2mol / L hydrochloric acid, then wash several times with deionized water and alcohol, and dry in a drying oven.

[0087] Among them, Co(NO 3 ) 2 ·6H 2 The molar ratio of O to red phosphorus was 1:4.5, and the concentration of surfactant (CTAB) in the suspension system for hydrothermal reaction was 2.85g / L.

[0088] (2) Then take 1g of dry Co 2 The P precursor was added to a 0.04mol / L glucose solution, then transferred to a 50mL Teflon-lined stainless steel autoclave, placed in an oven at 190°C, and reacted for 4 hours to obtai...

Embodiment 3

[0095] This embodiment prepares Co according to the following method 2 P / C composite material:

[0096] (1) 0.6112g of Co(NO 3 ) 2 ·6H 2 O, 0.3902g of red phosphorus and 0.15g of SDBS surfactant were added to 35mL of deionized water, and magnetically stirred. The obtained suspension was transferred to a 50 mL Teflon-lined stainless steel autoclave, placed in an oven at 220 ° C, and reacted for 30 h to obtain Co 2 P precursor. Then wash twice with 1mol / L hydrochloric acid, then wash several times with deionized water and alcohol, and dry in a drying oven.

[0097] Among them, Co(NO 3 ) 2 ·6H 2 The molar ratio of O to red phosphorus was 1:6, and the concentration of surfactant (SDBS) in the suspension system for hydrothermal reaction was 4.29g / L.

[0098] (2) Then take 1g of dry Co 2 The P precursor was added to a 0.08mol / L glucose solution, then transferred to a 50mL Teflon-lined stainless steel autoclave, placed in an oven at 200°C, and reacted for 2 hours to obtain ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com