Modified nano calcium carbonate as well as preparation and application thereof

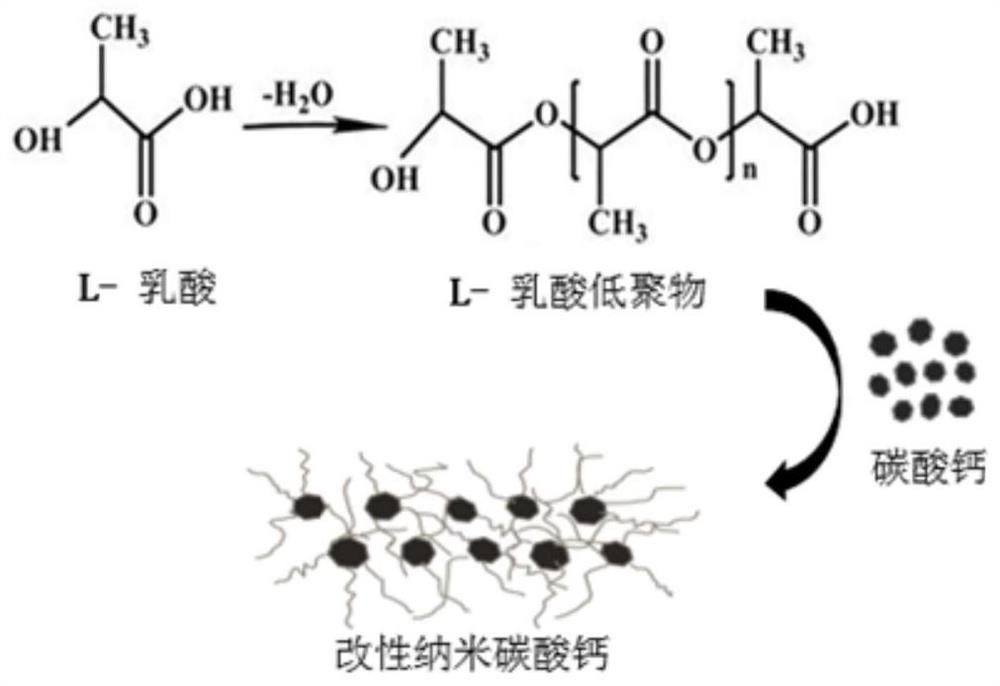

A nano-calcium carbonate and modification technology, applied in the direction of calcium carbonate/strontium/barium, nanotechnology, nanotechnology, etc., can solve the problems of poor compatibility between modifiers and polylactic acid matrix, and achieve increased mechanical properties and crystallization properties , Improve mechanical properties, promote the effect of natural self-degradation characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Take L-lactic acid and put it in the reaction container, and exhaust the air in the container by pumping vacuum to keep the vacuum degree at 0.1MPa. Heat the oil bath to 100°C for pre-dehydration for 1h, keep the reaction environment unchanged, raise the temperature to 135°C, and react for 2h . Use an oil pump to continue the vacuum reaction for 2 hours to obtain L-lactic acid oligomers with a number-average molecular weight of 300-400, and no catalyst is added in this process.

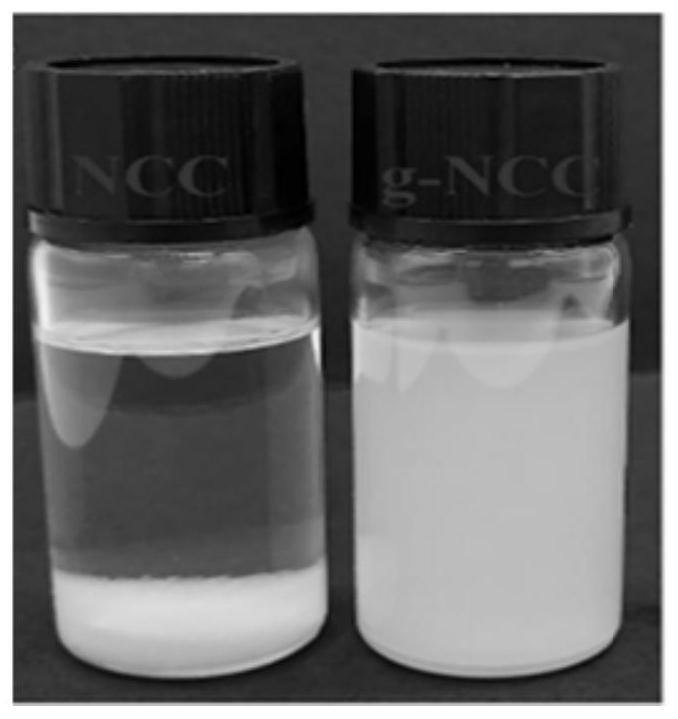

[0039] Take 2g of L-lactic acid oligomers, 8g of nano-calcium carbonate with a particle size of 50-90nm, disperse in dioxane and stir for 1 hour, then put the fully dispersed mixed solution under the conditions of 80°C and vacuum degree of 0.1MP Evaporate the solvent completely, raise the temperature gradient of the oil bath to 140°C, stir and react for 20 minutes, then cool to room temperature to obtain the pre-product, wash the pre-product 4 times with dichloromethane solution, dry it at 40°C...

Embodiment 2

[0042] Take L-lactic acid and put it in the reaction container, and exhaust the air in the container by pumping vacuum to keep the vacuum degree at 0.1MPa. Heat the oil bath to 100°C for pre-dehydration for 1h, keep the reaction environment unchanged, raise the temperature to 135°C, and react for 2h . Use an oil pump to continue the vacuum reaction for 2 hours to obtain L-lactic acid oligomers with a number-average molecular weight of 300-400, and no catalyst is added in this process.

[0043]Take 2g of L-lactic acid oligomers, 8g of nano-calcium carbonate with a particle size of 50-90nm, disperse in dioxane and stir for 1 hour, and then put the fully dispersed mixed solution under the conditions of 80°C and vacuum degree of 0.1MP Evaporate the solvent completely, raise the temperature gradient of the oil bath to 140°C, stir and react for 20 minutes, then cool to room temperature to obtain the pre-product, wash the pre-product with dichloromethane solution 4 times, dry it at 4...

Embodiment 3

[0046] Take L-lactic acid and put it in the reaction container, exhaust the air in the container by vacuuming with a water pump, keep the vacuum degree 0.1MPa, heat the oil bath to 100°C for pre-dehydration for 1h, keep the reaction environment unchanged, raise the temperature to 135°C, and react 2h. Use an oil pump to continue the vacuum reaction for 2 hours to obtain an L-lactic acid oligomer with a number average molecular weight of 300-400, without adding a catalyst in this process.

[0047] Take 2g of L-lactic acid oligomers, 8g of nano-calcium carbonate with a particle size of 50-90nm, disperse in dioxane and stir for 1 hour, and then put the fully dispersed mixed solution under the conditions of 80°C and vacuum degree of 0.1MP Evaporate the solvent completely, raise the temperature gradient of the oil bath to 140°C, stir and react for 20 minutes, then cool to room temperature to obtain the pre-product, wash the pre-product with dichloromethane solution 4 times, dry it a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com