Method for absorbing hot galvanizing acid mist and co-producing calcium chloride

A technology of hot-dip galvanizing and calcium chloride, applied in the field of comprehensive utilization of resources, can solve problems such as corrosion of plant equipment, pollution of plant environment, acid mist pollution, etc., and achieve comprehensive utilization of resources, high acid mist absorption rate and simple process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

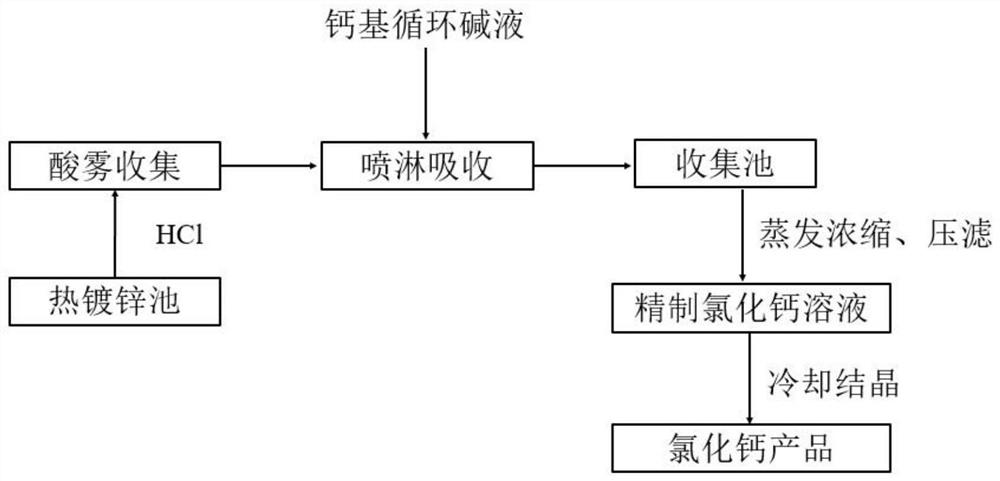

Image

Examples

Embodiment 1

[0035] Collect hot-dip galvanizing acid mist from the hot-dip galvanizing pool (the content of HCl is 10mg / m 3 ), the hot-dip galvanizing acid mist is introduced into the spray tower through the pipeline by an induced draft fan, and then a calcium-based circulating lye (lime milk supernatant obtained by mixing quicklime and water with a pH value of 12) is used in the spray tower Perform spray absorption to obtain a calcium chloride solution; collect the obtained calcium chloride solution in a collection tank and perform evaporation and concentration to make the mass fraction of the calcium chloride solution 45%, and then perform pressure filtration to obtain a refined calcium chloride solution. After cooling and crystallization (0°C), a calcium chloride hexahydrate product is obtained with a purity of 98.5% and an acid mist absorption rate of 95.4%.

Embodiment 2

[0037] Collect hot-dip galvanizing acid mist from the hot-dip galvanizing pool (the content of HCl is 20mg / m 3 ), the hot-dip galvanizing acid mist is introduced into the spray tower through the pipeline by an induced draft fan, and then a calcium-based circulating lye (the supernatant obtained by mixing calcium carbide slag and water with a pH value of 12.5) is used in the spray tower Spray absorption to obtain calcium chloride solution; collect the obtained calcium chloride solution in the collection tank, evaporate and concentrate, so that the mass fraction of calcium chloride solution is 50%, and then press filter to obtain refined calcium chloride solution. Perform cooling crystallization (10°C) to obtain calcium chloride hexahydrate product with a purity of 98.5% and an acid mist absorption rate of 96.1%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com