Gypsum self-leveling material with high water-retaining property and preparation method thereof

A self-leveling and water-retaining technology, applied in the field of building materials and mortar, can solve the problems of poor mortar water retention, low mortar strength, poor mortar cohesion, etc., achieve good water retention and workability, stable mortar system, and ensure construction sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

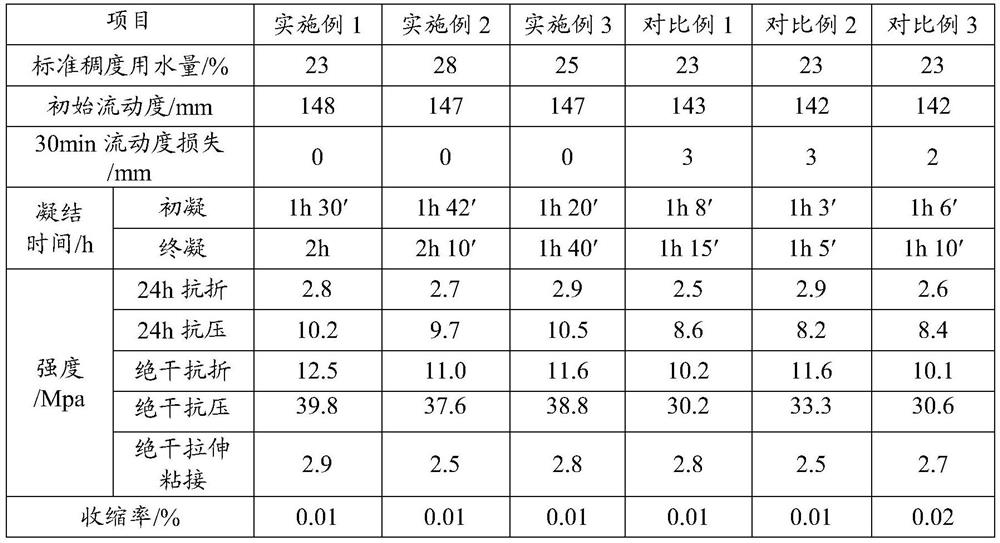

Embodiment 1

[0053] Take 40 parts by weight of high-strength gypsum, 15 parts by weight of 40-70 mesh river sand, 20 parts by weight of 70-140 mesh river sand, 8 parts by weight of heavy calcium with a particle size of 400 meshes, and 8 parts by weight of slag Portland cement with a strength grade of 32.5 , 7 parts by weight of nano ultrafine calcium carbonate with a particle size of 0.1 μm, and 2 parts by weight of Wacker Chemical 5010N rubber powder; 0.02 parts by weight of the produced cellulose ether water-retaining agent MH300P2, 0.008 part by weight of the retarder 200P produced by Sika, and 0.04 part by weight of the defoamer P8850 produced by AGITAN, Germany, were used to form the admixture. Mix the main material and the admixture evenly to prepare a gypsum self-leveling material with good water retention, and mix the prepared gypsum self-leveling material with water in a weight ratio of 1:0.23 to make a gypsum self-leveling mortar with good water retention .

Embodiment 2

[0055] Take 45 parts by weight of building gypsum, 10 parts by weight of 40-70 mesh ore sand, 20 parts by weight of 70-140 mesh ore sand, 10 parts by weight of 300 mesh heavy calcium, and 5 parts by weight of ordinary Portland cement with a strength grade of 42.5. 9 parts by weight of nanometer ultrafine calcium carbonate with a diameter of 0.02 μm and 1 part by weight of Wacker Chemical 5044N rubber powder are the main ingredients; 0.10 part by weight of polycarboxylic acid water reducing agent LonS-P(H) produced by Zhejiang Longsheng Company , 0.04 parts by weight of cellulose ether water-retaining agent MH300P2 produced by Shin-Etsu Company of Japan, 0.010 parts by weight of retarder PE produced by SICIT 2000 Company of Italy, and 0.04 parts by weight of antifoaming agent P88566 produced by AGITAN, Germany to form admixtures. Mix the main material and the admixture evenly to prepare a gypsum self-leveling material with good water retention, and mix the prepared gypsum self-l...

Embodiment 3

[0057] Take 25 parts by weight of high-strength gypsum, 25 parts by weight of building gypsum, 9 parts by weight of 40-70 mesh sand, 21 parts by weight of 70-140 mesh sand, 8 parts by weight of 300 mesh heavy calcium, and a common silicate with a strength grade of 52.5 6 parts by weight of cement, 7 parts by weight of nano-ultrafine calcium carbonate with a particle size of 0.05 μm, and 1 part by weight of Wacker Chemical 5010N rubber powder are the main ingredients; the polycarboxylate water-reducing agent LonS-P produced by Zhejiang Longsheng Company is taken as the main ingredients. (H) 0.15 parts by weight, cellulose ether water-retaining agent MH300P20.05 parts by weight produced by Shin-Etsu Corporation of Japan, 0.012 parts by weight of retarder P produced by Italian SICIT 2000 company, and 0.06 parts by weight of defoamer P8856 produced by AGITAN, Germany admixtures. Mix the main material and the admixture evenly to prepare a gypsum self-leveling material with good wat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com