A kind of gypsum board and preparation method thereof

A gypsum board and gypsum powder technology, applied in the field of building materials, can solve the problems of restricting the use of moisture-conditioning gypsum board, reducing the mechanical properties of gypsum boards, and not being reported in literature, and achieving unaffected construction performance, reduced areal density, Solve the effect of easy powder

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

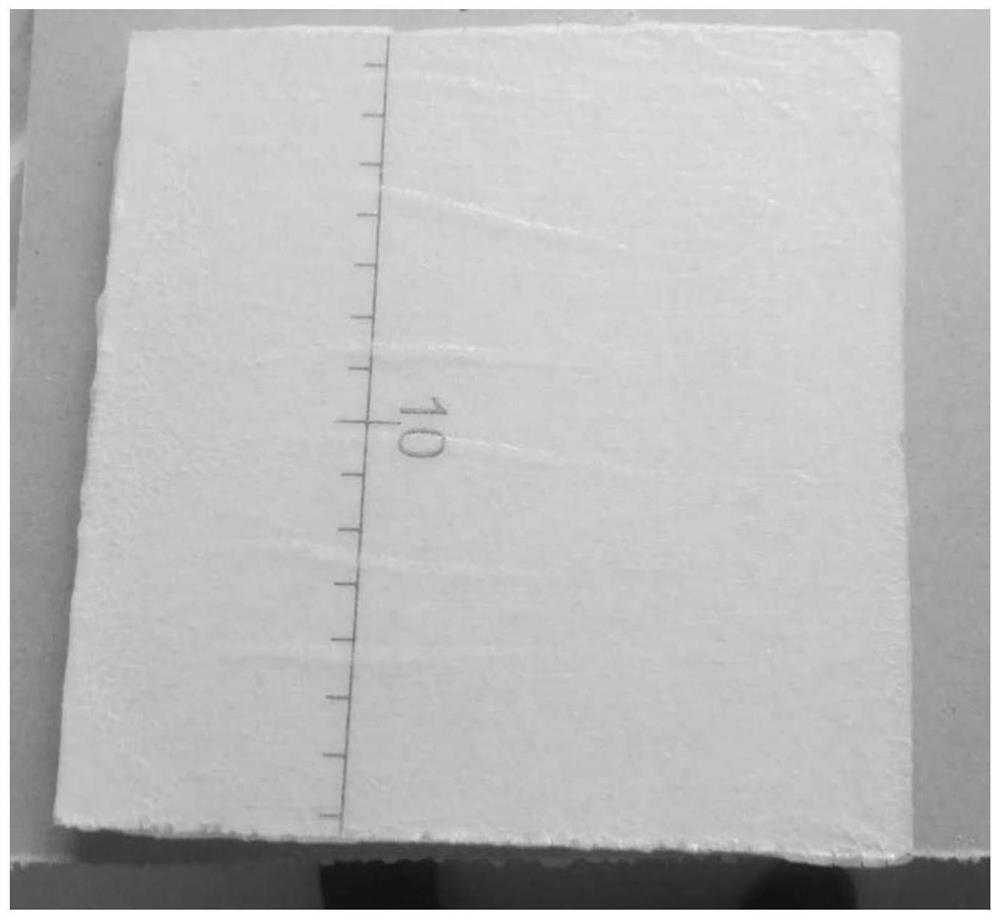

Image

Examples

Embodiment 1

[0068] Pass 1000 grams of gypsum powder through an 80-mesh sieve. 60 g of zeolite was passed through a 200-mesh sieve, and then the zeolite was calcined in a muffle furnace (400° C.) for 2 hours, and then cooled in a desiccator for later use. 50g of diatomaceous earth is dried and dispersed in an oven for subsequent use. Mix the treated gypsum powder, zeolite, diatomite and silica micropowder (30g), ordinary Portland cement (30g) and tapioca starch (7g) whose strength grade is 42.5#; Determine the amount of water used for the standard consistency of the powder mix. Taking by weighing concentration is the silica sol solution 25g of 40wt%, according to the content of the water consumption in the standard consistency water consumption and the silica sol solution, takes by weighing mixing water, mixes water and mixing powder, blowing agent (0.35g, SASN812) were stirred together to prepare a slurry. The prepared slurry is flatly spread on the lower protective paper, and the upp...

Embodiment 2

[0073] The preparation process and method of Example 2 are exactly the same as those of Example 1, except that the coating formula is different. The coating formulation is as follows:

[0074] Put 8g of color-changing silica gel in a pulverizer to pulverize, pass through a 200-mesh sieve for use after pulverization. Mix discoloration silica gel powder, 40g polyacrylic acid emulsion, 0.8g silica sol solution (concentration: 29%), and 2g diatomaceous earth evenly. Get the above-mentioned preparation paper surface gypsum board (area density is 6kg / m 2 , the thickness is 9.5mm), the interception size is: 200mm×200mm. The above-mentioned mixed solution is divided into 10 times and evenly painted on the gypsum board, and the brushing interval is 5 minutes.

Embodiment 3

[0076] The preparation process and method of Example 3 are exactly the same as those of Example 1, except that the substrate formulation is different. The amount of silica sol added in the substrate formulation was 100 g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com