Cholic acid extract and extraction process

A technology for extracting and cholic acid, which is applied in the field of extracting cholic acid from poultry gall, can solve the problems of cumbersome steps, prolonging the production cycle, and inability to remove oil well, achieve low reaction temperature, simplify the production process, and reduce the destructive effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Collect fresh duck gallbladder, cut the gall bladder, and collect fresh bile. Take 1000 g of bile and centrifuge at 1450 rpm for 20 min. After the centrifugation is completed, collect the filtrate. Add 10% dilute sulfuric acid under normal temperature conditions, adjust the pH to 3, let it stand for a period of time, and remove the upper layer of grease after the grease is separated.

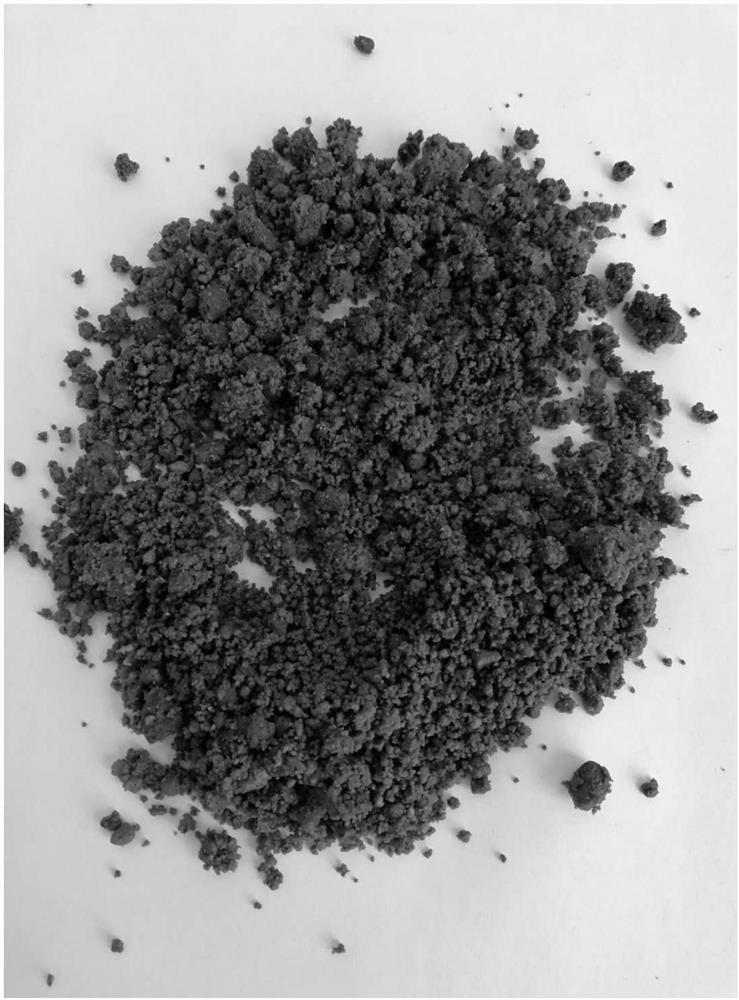

[0041] Weigh the remaining bile to be 900g, add 800ml of 10% potassium hydroxide to it, keep the temperature of the reactor at 100°C to carry out saponification reaction, and react for 24h. After the saponification reaction is completed, add 10% dilute sulfuric acid again to adjust the pH of the solution to 2, stir slowly until yellow precipitate particles appear in the solution, and then centrifuge to obtain the yellow precipitate part. The yellow particle part is 210 g after weighing, and the yield is 21%.

Embodiment 2

[0043] Collect fresh chicken gallbladder, cut the gall bladder, and collect fresh bile. Take 1000 g of bile and centrifuge at 1480 rpm for 20 min. After the centrifugation is completed, collect the filtrate. Add 8% dilute sulfuric acid under normal temperature conditions, adjust the pH to 4, let it stand for a period of time, and remove the upper layer of grease after the grease is separated.

[0044]Weigh the remaining bile to be 910g, add 1000ml of 8% potassium hydroxide to it, keep the temperature of the reactor at 95°C to carry out the saponification reaction, and react for 20h. After the saponification reaction is completed, add 8% dilute sulfuric acid again to adjust the pH of the solution to 3, stir slowly until yellow precipitated particles appear in the solution, and then centrifuge to obtain a brown precipitated part. After weighing, the brown particle part is 200 g, and the yield is 20%.

Embodiment 3

[0046] Collect fresh duck gallbladder, cut the gall bladder, and collect fresh bile. Take 1000 g of bile and centrifuge at 1400 rpm for 23 min. After the centrifugation is completed, collect the filtrate. Add 12% dilute sulfuric acid under normal temperature conditions, adjust the pH to 3.2, let it stand for a period of time, and remove the upper layer of grease after the grease is separated.

[0047] The remaining bile was weighed to be 920g, 700ml of 12% potassium hydroxide was added thereto, and the temperature of the reactor was kept at 100°C to carry out the saponification reaction for 27h. After the saponification reaction is completed, add 11% dilute sulfuric acid again to adjust the pH of the solution to 2.8, stir slowly until yellow precipitate particles appear in the solution, and then centrifuge to obtain the yellow precipitate part. The yellow particle part is 192g after weighing, and the yield is 19.2%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com